Scheduling room heating device by means of different technologies, including new installation of floor heating by a heating cable sets itself apart from other types of heating. And as practice shows, it is electric underfloor heating under tiles, It is the most profitable and convenient form of individual room heating in all categories of the comparison of the economic viability, to the convenience of work. but, in spite of such attractive prospects, Some knowledge of the nuances of electric floor heating device under the tiles will not only make the right choice, but also independently, without outside help establish a whole set.

Criteria for selection of premises heating technology

Consider the real reason for the popularity and convenience of the device different heating systems allow comparison highlights, related planning, Design and installation of various heating systems for individual use.

comparing, Various systems for installation, a prerequisite in this case is the presence of a floor ceramic tiles, such coverage is becoming increasingly popular not only in bathrooms and kitchens, ceramic tile is increasingly used for the coating device in the corridors, as a combined coating for studio Improvement. detail: installation of underfloor heating under tiles.

For gas heating installation for heating floor heating system requires the installation of pipeline under the floor surface. The possibility of using in this case a standard heating boilers, with the principle of natural circulation of the coolant immediately faced with the problem of additional installation of the circulating pump. Besides, included in the total radiant floor heating scheme will require to warm up the room, eg, in rainy weather in early autumn or spring inclusion of the entire system, rather than a separate room. Detailed information on Installation of water underfloor heating.

Electric underfloor heating under tiles based on infrared technology heating elements, It is not quite suitable for tiling, this embodiment for laminate.

But the heated floor tiles under the electric cable is the best option for installation, because even at the stage of the calculation and documentation of the project does not require the manufacture and its coordination with a large number of organizations, in heating gas. Moreover, in contrast to the film embodiment, It does not require constant care of waterproofing - cable is double PVC insulation, securely enclosing the conductors from moisture. In addition to installing the electrical part does not require special skills, That's really what you need to carefully watch instructional videos and additional read the manual.

Another advantage is the Finnish Cable floor heating under the tiles is the possibility of management of heating buildings directly via thermostats, and by means of remote access by logging on to the computer system over the Internet.

Well necessarily need to point out the economic component of the project - for gas heating is the gasification project, permission, project, equipment and labor costs, costs of acceptance and authorization for commissioning. For electric underfloor heating cable on the basis of - only the cost of equipment, with the purchase of a lot of variants from the nearest building market with a guarantee of six months, to order a full set of equipment from a global manufacturer with 10-year warranty and all instructions and video courses.

How to choose the most suitable option

Underfloor heating Electric under the tile in the usual sense of consumers is primarily a cable laid in the concrete screed and plugged into the socket on the principle of heating pads. In principle, this is true, or almost so, since the structure and provides an electrical heating cable and the power supply system. But with respect to everything else here it is not so. The assembly of electrical floor, and we must pay tribute to manufacturers from Europe as the Finnish engineers, and the Czech and German for them, It is primarily a clearly worked-out system, consisting of several elements:

- management and control systems;

- equipment protection system;

- heating elements.

Wherein, eg, Finnish development company ENSTO Finland offers a comprehensive approach - the kit is calculated not only cable, but the programmer, Liquid heating controller display, temperature sensor, and except for the cable compulsory is mounting tape and instructions for installation.

This integrated approach is typical when ordering equipment from ProfiTherm (Poland-Germany), Nexans (Norway).

Danish concern Devi (Denmark) in the arsenal offers, among other things, optional equipment, allowing eventually transform the home into a super-modern "smart home" to control a heating system with a smartphone screen literally from anywhere in the world, with Internet.

Danish concern Devi (Denmark) in the arsenal offers, among other things, optional equipment, allowing eventually transform the home into a super-modern "smart home" to control a heating system with a smartphone screen literally from anywhere in the world, with Internet.

certainly, this decision a bit more expensive compared to the conventional way of using domestic heating cable with the nearest market, but also with the assembly and installation of floor heating under the tile will cost less difficult, It will allow significant savings already just in the first heating season. In this case, the system can be collected by analogy with firm, but using domestic components. details, see, about the choice of electric heating cables.

Planning floor heating device

Optimal for planning such a heating system is a time of detailed design of building construction or repair of premises, when it is possible in practice to calculate the required amount of materials and the most efficient distribution of a location control unit. And think, how to make a reliable wiring to the control unit, because for such equipment, as the electric floor heating require a separate, reliable power line.

Calculator to calculate the power of sex

With the online help calculator electric underfloor you can calculate the power.

Considering options for styling, it should be understood what layout of furniture and home appliances is planned in the future. This is particularly important in order not to carry out additional wiring under the kitchen unit or bath. Sounding realistic thing to do on the spot, the distance between the cable lines should be at least two cable turning radius, eg, Danish for "Devi" is 10 cm. In the reality, for economical heating and constant maintenance of indoor comfort 22-23 degrees is enough to make a move in 12-15 cm between the cable lines.

Offset from the external walls is recommended to be done in 10 cm, and from internal 5-7 cm. When calculating the recommended immediately make the stock on 10-15% the calculated cable length. In the calculations, it is recommended to take into account:

- perimeter of the room to install a thermal insulation barrier;

- floor area calculation foam polystyrene insulation, waterproofing layer, calculate the number of tiles.

- placement height control units - It depends on it, as corrugated sleeves need and how long it will be necessary to order wire sensor.

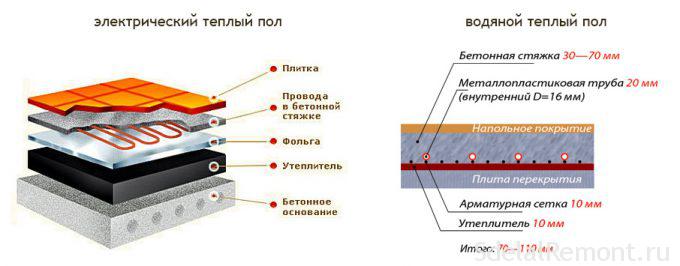

Warm electric floor under the tile in its design is a bit like a layer cake with many layers, each of which has its own technology and styling appointment. So you need to consider each of the elements in more detail.

base cushion stacking technology

considering, electric device under the tile floor on the basis of the heating cable, taken classic example of such a heating device using all layers and their construction technology.

The basis for the apparatus of the first insulation layer acts as a concrete floor slab. The surface of the subfloor is cleaned of debris and dust, and processed primer possible to enhance the surface layer. Further, held device thermal insulation of walls - no thinner foam 1 see on the perimeter is arranged to contour height 10 cm. The next step serves floor laying insulation, typically by at least the thickness of the foam 2 cm and a density of not less 35-45 units or uses extruded foam thickness 2 cm.

Atop this coating film is carried out styling thermally insulating foil layer. Material upward travel along the foil, with the edge it needs to make the walls of at least 10 cm and secure masking tape.

For concrete screed using an additional reinforced belt of metal mesh or reinforcement diameter 6-8 mm increments 15-20 cm. Fill cement concrete is carried out on the basis of cement M450 or M500. The thickness of the screed must be at least 5 cm. Special attention is paid at that stage of the formation of a flat surface. Flooded screed must dry completely natural way, without additional effects and drying. Alternatively accelerate drying is allowed to use the plasticizer in concrete, but at the same time such a plasticizer should be approved for use indoors. Continuation of work on the further installation of a warm floor under the tile is recommended to start no earlier than, than 3 day. When the concrete starts to gain its commodity strength.

Installation of underfloor heating

Easy to install underfloor heating under tiles is comparable with the assembly designer, as well as in the constructor contains instructions and have the right amount of details and also there is a picture with the end view of the finished structure.

Initially installed in the walls of the space for the controls and set the box for these items. Conclusions power wires at this stage simply be entered into the box and is isolated, safety advice must be observed at all stages of installation. From the box into the prepared indent in the wall of stacked corrugated hoses - one for the temperature sensor, one for the heating cable. Corrugation sensor extends for 1-1,5 meters of floor. End insulated PVC electrical tape to prevent ingress corrugations concrete mortar and moisture.

Mounting tape to attach the cable is laid out perpendicular to the direction of cable laying. She just nails nailed to the floor. step driving 15-20 cm. The distance from the exterior wall to the mounting tape - 15 cm.

cable laying begins with the installation of the terminal coupling, part of the kit, it is set at the end of the cable, which is mounted in a remote location design. With the help of pliers, or pliers cable is fixed on the mounting tape. Cabling must not have sharp bends and fractures. Each intersection of the cable element and the mounting tape to be recorded. The heating cable is laid without tension, but he should not be free and dangling.

Cable end closure after stacking cut with the margin for mounting the control device. After the end of the corrugated pipe is introduced into the cable mounting box.

Simultaneously set temperature sensor. He just is pushed the corrugation. Upon completion of this phase of work on a mandatory basis is checked with a tester the resistance of each of the cores and the entire cable is fully.

At this stage, usually professional installers connect control system and test performance.

If there is a particular need to conduct a trial run of the system, then later during the screed or tile not only turn off the power, and if possible remove the control unit and electrically insulated to prevent accidental startup!

Preparation for laying tiles

Installing electric underfloor heating under tiles on cable installation phase does not end, must, Besides, make a screed for laying of tile.

Traditional screed under tiles should be at least 4-5 cm, and it is desirable to have additional reinforcement, but in view of the, that are laid thermal cable is recommended to use a special mix for thermal papers, but instead use a metal reinforcement fabric reinforcing mesh.

The thickness of this tie will be no more 1,5-2 cm. Ties are recommended to fill in one pass. It is important to work with was not the heating cable damage, because if it is damaged will have to carry out the installation of underfloor heating in a new way. Therefore it is recommended to use self-leveling screed and roll with plastic spikes rounded.

Laying tiles carried out on frozen tie after the final drying. As the adhesive is recommended to use a special adhesive finished termosmesi.