When entering any premises in the eye catches floor, the quality of its execution. To any flooring laid down nice and smooth, It must be appropriately configured draft, there is a reason. That it would be desirable to spend, as little time. For this purpose, and was invented a mechanized floor screed in the apartment. It is performed with the help of special equipment, allows everyone in the shortest possible time and with high quality.

Application area

This embodiment is performed in semi-dry screed case, when the final coating will be in the final result,. These include warehouses, garage structure, etc.. The same applies to subsequent decorating floor. That is, if we take into account the evenness of the surface.

mechanized screed floor apartment done if desired to obtain a qualitative and a solid foundation for flooring. After all, the evenness of the surface is important for such floor coverings, as laminate or parquet. Labor costs here are minimal, true, this semi-dry screed pricing is quite high due to the use of the expensive equipment.

When a person doubts, polusuhaya screed or usual it is better, here will depend on the desired result. When required subfloor as an additional insulation layer, then, without mechanized versions do not. It also easily allows to hide the available communication elements, piping or wiring. Moreover, in the solution used minimal amount of water, that extends the range of application in terms of the base to a semi-dry screed.

Pros mechanized tie

Not only the production rate of the semi-dry screeds distinguishes it among other options devices subfloor. The benefits of application include:

- Lower labor costs in high performance.

- Gaining strength solution promptly.

- There is no need to apply a steel net as a reinforcing material.

There are enough alternatives, which reduces the overall weight and have better properties, specifications.

There are enough alternatives, which reduces the overall weight and have better properties, specifications. - The excellent properties of thermal and sound insulation of the finished base.

- Small amounts of water in the resulting solution.

- The absence of shrinkage cracks.

- plasticizer for semi-dry screeds, as well as any other additives allow to make the solution more plastic and able to withstand the various loads.

- According to semi-dry screed services are mainly provided by specialized firms, Available from all the necessary equipment. The result of this it is much better.

The use of fiberglass and other components

The solution was prepared by addition of water may be added and other components, among which there is a reinforcing agent - fibrovolokno. Semi-dry mixture usually contain all elements in one bag, in which it is enough to add the required amount of water. The main thing is not to sort.

With fiberglass combined optimally sea sand, fraction having to 0.05 mm. Brand of cement - at least M500, as well as other possible substances, presence of which will depend on the particular circumstances, weather conditions and requirements to the base for flooring flooring.

Fiberglass replaces all the usual steel mesh.  At the same time it increases the strength characteristics of the sub-floor, prevents cracks formed on the surface. When adding fiber to the dry mixture, for self-preparation solution, it must be uniformly mixed with all components, and then you can pour water. Stirring is until, until you have a smooth paste. Fiber is very easy to connect with them.

At the same time it increases the strength characteristics of the sub-floor, prevents cracks formed on the surface. When adding fiber to the dry mixture, for self-preparation solution, it must be uniformly mixed with all components, and then you can pour water. Stirring is until, until you have a smooth paste. Fiber is very easy to connect with them.

The semi-dry screed exhibits positive characteristics only, when all the proportions in line with the manufacturer's. Especially it concerns the addition of water, excess which leads to the appearance of cracks and numerous places shrinkage.

Mounting ties

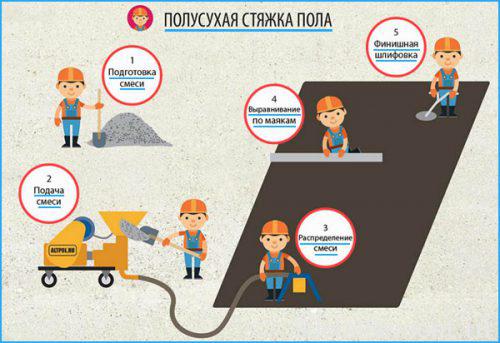

The first step is to prepare the ground for performing semi-dry screeds mechanized method. For this purpose, any debris is removed, dust, mud, closed up to the maximum cracks and potholes in the ceiling. We can not forget about a waterproofing layer and brackets along the perimeter walls and architectural structures damper tape.

Upon completion of the preparatory work with the help of special equipment, characteristic for this method screed, kneaded solution is supplied into the room through the hoses. Filling should be performed on the beacons, which are installed with the help of lasers.

Using the usual rule, solution is distributed uniformly throughout the room, Root can work from any angle, Located away from the entrance to the room. To perform semi-mechanized tie will be enough of one man, which will be the operator. But it is worth remembering, after that for 6 hours necessary to make the grout and sanding base.

Grinding semi-dry screeds done using trowels machines. work capacity is reduced when they are used much. Besides manually unevenness is unlikely to succeed to eliminate.

In addition, cut expansion joints. Their main purpose - to get rid of possible defects, which arise from the shrinkage. Most often, the joints eliminate cracks.

The result is a very smooth surface, on which later 12 hours, you can safely move. Depending on the used floor covering, in certain situations, even after a week, you can make him packing.

cost of

When it comes to such an embodiment of rough sex, all think about, how much is semi-dry floor screed material. As for the material, the price is likely to be even lower, than the installation of the concrete surface. Top misappropriation involving the application of special equipment.

Equipment to perform mechanized semi-dry screed can be leased. enough companies, specializing in a given direction. But more than the best option - to order the installation of the sub-floor in the building firm. They will surely be all at your fingertips, to achieve a positive result in. true, remuneration will be appropriate. One has only to note, it is unlikely that anyone will perform a semi-dry screed in such a way in a small room about area 15 m2. In such a case, the use of special equipment is very expensive and impractical. Probably better to choose dry screed technology via filling.

Rental equipment fully cost about 8-10 thousand. Prior to this, it is worth thinking about, whether there is a desire to spend such sums for repairs in the apartment. Semi-dry floor screed with their hands the apartment will cost slightly cheaper, if this still use the mixer , rather than special equipment.

Painting

Not always have the desire to lay flooring in the rough floor. Finish thus it must be brought into the proper form.  Owners of storage facilities or leased space often think about, than to paint a semi-dry screed.

Owners of storage facilities or leased space often think about, than to paint a semi-dry screed.

The large number of painting materials in the sale raises questions about, that we want to get in the end. This may be a sturdy surface, smooth, colorful, bright, allowing to avoid the effects of external influences. Some paints can withstand abrasion during operation.

Everything will depend on the size of the purse and the requirements of the customer.

Tips

Each specialist semi-dry screed can give advice to the novice builder, or the, who wants to own forces to carry out repair work in the house or apartment.

Very important drying the cast solution, and meticulous care after him. It is impossible that the room there is a large amount of the sun's rays, as well as drafts. This is the negative side affects to the surface, which dries unevenly. To get rid of possible cracks, no harm will apply to the special additive solution, which abound in the range in DIY stores.

It is worth noting, that complete drying screed at all times is reached only a month after the completion of the work. It is important to comply with the requirements of care. Depending upon the floor covering, work on his deck can start and after a week and a half. In any case, it is necessary to look carefully at the condition and moisture content of the surface of the subfloor.

After this is unlikely to be questions about, which is better - screed semi-dry or normal. Positive qualities mechanized laying method inclines solution on its side. It is also no small importance is the ease of installation and low knowledge of the construction industry. true, basic requirements and nuances must be observed constantly and technology to adhere to a semi-dry screeds.