To align the floor in any room are increasingly give preference to semi-dry screed. This is connected with the basic features, is the rapid installation and use with a minimum of water. It resembles the grout, but brings less red tape. It is important to observe the solution stacking technology, selecting a suitable thickness for.

general information

During execution semi-dry screeds increasingly began to use dry ready-mix, that make the job easier and more convenient. As the reinforcing agent is selected from a steel mesh material, fiberglass. To reduce the load on the overlap and improve the strength characteristics - acquire fibrovolokno.

The concrete mixture dries much faster due to the small amount of water. The average term of 5-6 days. These figures are roughly in 5 times faster, than fill a "wet" ties.

medium-dry  subfloors device embodiment may be performed as in concrete slabs, and the wooden base. Do not play the role of a room, where the installation is performed, and used in subsequent floor. the main thing, that technology is respected in all stages of.

subfloors device embodiment may be performed as in concrete slabs, and the wooden base. Do not play the role of a room, where the installation is performed, and used in subsequent floor. the main thing, that technology is respected in all stages of.

It is worth noting, that very carefully defined thickness semi-dry screeds. At the height of the finished cake influence certain factors.

factors, influencing the thickness

There are certain conditions, which affect the thickness of the floor screed. It's not just the technology itself, but also:

- Specifications Operating room, where the works on the device of the subfloor. The greatest load on the floor in the corridors, kitchen and hall. So we should not think of the minimum rates in these areas, and make some more required.

- Flooring, which will lay a foundation prepared after drying.

- Material, which is filled polusuhaya screed, and the state itself of the coating. The more irregularities, the greater the need to arrange a layer of semi-dry screeds. If you pay attention to the building regulations, the minimum rate is set to the thickness where 20 mm. It is important in such a thin layer of reinforcement to think about, that she did not give a time rift.

- Materials for the semi floor screed, used in the process.

Each of these factors add or reduce the overall thickness and creates conditions for use in mounting additional moments. But in no way suggests that, which is very thin or very thick base to be more effective, in difference from each other. In this case, there are subtleties and nuances. For each case should be approached individually.

Materials used

When there is no desire to mix your own solution for semi-dry screeds, you should consider purchasing the finished versions. Dry mixes in the structure already contain all the components required to produce the desired result. They include:

- Sand.

- Cement.

- fiberglass.

- plasticizer.

It is worth noting, that the semi-dry screed with fiberglass has much better qualities, the simple application of the installation of steel mesh. It gives the plasticity of the solution, allowing it to evenly flatten the surface of the prepared base. In addition, you end up with an even subfloor, having high strength indicators.

Brand semi screed will directly depend on the grade utilized in the composition of cement. The higher the score, the better will be the strength of the result. Semi-dry screed in this case will turn out really strong and reliable. By increasing the brand will grow slightly and the cost of the finished mixture for solution.

Building sand or river selected.  Its fraction should not exceed five millimeters. It is necessary to closely monitor the humidity, since it will depend on it and the amount of water added to a solution of.

Its fraction should not exceed five millimeters. It is necessary to closely monitor the humidity, since it will depend on it and the amount of water added to a solution of.

Plasticizing agents are included in the semi-dry floor screed and the mixture while outwardly no different. But the quality of the final solution obtained by high. When he was preparing yourself, the plasticizer can be purchased separately, adding a certain amount depending on the amount. The plasticizer can be found in any hardware store.

For the most part also is attributed and is, that semi-dry floor screed ready-mix is much faster. In addition, one should not think about the proportions, which are very important in this case,.

reinforcement of the surface

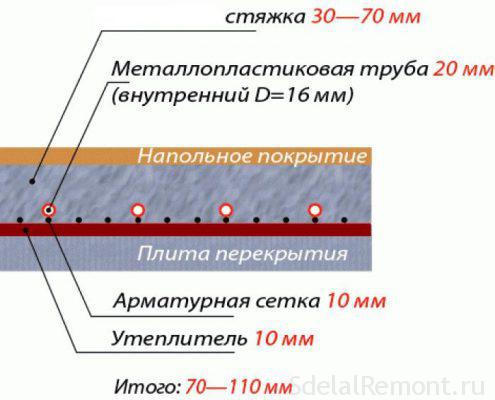

When a semi-dry floor screed, thickness will depend, including by reinforcing layer. All familiar in this case is a stainless steel wire mesh, with a mesh size 10*10 mm. But it starts to go in the direction of increasing the weight of the finished design on the ceiling.

To replace the semi-dry screed comes with a fiber.  This component is easily "introduced" in the all the components of the mixture and turns integrally. The coating as a result becomes more durable, durable and solid, able to withstand any loads and decking flooring without exception.

This component is easily "introduced" in the all the components of the mixture and turns integrally. The coating as a result becomes more durable, durable and solid, able to withstand any loads and decking flooring without exception.

Steel mesh increases and the total thickness of the subfloor. installation process will look stretched due to the creation of additional work stages: filling mixture, laying a reinforcing element, finishing work. WITH fiberglass it's much easier and more convenient.

The choice of thickness

To begin to explore the very foundations of the subfloor. From him and will be used in determining the thickness of the semi-dry screeds. Sufficient will carefully examine externally. Do not spend more than a rack of metal about a meter long. She points to the existing uneven part, as well as significant projections. These defects are manifested not only in old buildings, but also to newly built houses. The accuracy of the laser level will perform.

Semi-dry cementitious screed comes from the training grounds. The smoother the surface will, the smaller the amount of the solution will have to spend at work.

The need to determine the minimum

Minimum performance thicknesses semi-dry screed must be determined in the case, when there are installed communication system or underfloor heating. Having a very large layer subfloor, decreasing the distance from floor to ceiling. This is particularly evident in low areas.

Above the floor heating minimum thickness should be 35 mm. This level is set immediately after the end of all its elements. Thick floor increases the cost of space heating, since a long time is impregnated with heat itself screed, and not to mention about another barrier - floor.

Most floor thickness exerts pressure on the overlapping.  It appears most often on balconies. And immediately increase the drying time. The material with the passage of time tends to expand. This can subsequently cause the pressure on the wall, if the layer is too massive.

It appears most often on balconies. And immediately increase the drying time. The material with the passage of time tends to expand. This can subsequently cause the pressure on the wall, if the layer is too massive.

If the mixture does not include any additional reinforcing agents, then it must be the minimum thickness 40-50 mm. About the thickness can learn a lot of packaging for a mixture. Recommended settings there is always displayed. Manufacturers always have to worry about the final result.

According to the SNIP for laying semi ties immediately on the floor slab, it should be a minimum thickness 20 mm. In the presence of an additional waterproofing layer - 40 mm.

maximum performance

Maximum limits for the tie is not available. All will depend on the need for communication or hide any surface irregularities. But one should be careful, not to have a strong burden on the overlap.

Experts recommend not to come from the minimum layer semi-dry screeds, and take it a few more. A small value will rise to cracks and chips on the surface, which will lead to a repeat of the work.

As almost every basis for sub-floor is uneven in a few centimeters, then screed, generally, will receive an order 50-60 mm. At each level of the ceiling it should be at least 30-35 mm. Some places are more, some limits on the minimum. This is also necessary in order, water to uniformly evaporate until dry.

Laying tiles is not always performed at a decent level. sometimes even, that the drop is more 60 mm. In this case it is best to use a solution of peskobeton coarse fraction of sand. In this case, the thickness of the semi-dry screed can reach up to 15 cm. If you have to make it even more, then come to the aid keramzit, able to cut costs.