floor screed can be performed using a variety of materials. It all depends on the purpose, as well as the desired result. Under certain circumstances, semi-dry screed can be arranged under the "warm floors" or under any floor covering. It is not uncommon installation "rough" sex on a concrete block, which is famous for its main advantages. Also here it is important to comply with the technology itself, so as not to appear the negative effects.

Pros and cons of expanded clay

The use of semi-dry screed expanded clay has a major positive qualities:

- Such a floor is not afraid of severe frosts, and high temperature. No heat will not damage the base of the sub-floor. Semi-dry screed with expanded clay can be done even in the premises, that are not heated during the year.

- With the use of expanded clay eliminates any irregularities, what height they were not. Perhaps floor screed device to a height of 150 mm. Some mixtures may then be powerless.

- using claydite, You can be sure, that does not manifest itself rot, it resists high temperatures, as well as the formation of corrosion. Service life is very long.

- The basis of expanded clay - baked clay. It weighs much less, than conventional concrete. Pressure and stress on the overlap is reduced to a minimum performance. It can be used even on a wooden base.

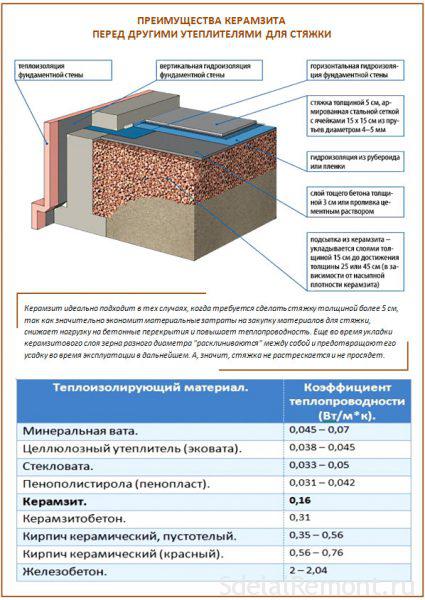

advantages of expanded clay

Among the disadvantages of instability is particularly disturbing this material to moisture. For this reason, there are some limitations on its use in certain circumstances.

Expanded clay should be kept under a special canopy or even indoors. The fact, that the material absorbs moisture very well, but slowly releases it. In this case, renovated, the room will be a long time to keep humidity.

types of fillings

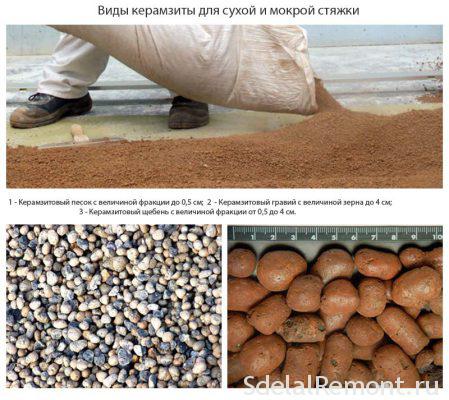

keramzita different density. The product range is presented on the construction market. It only remains to choose a more suitable embodiment of the device semi-dry screeds in room. The density may range from 250 to 600 kg per cubic meter, that meets certain circumstances the use. Depending on the type of release:

- crushed stone. The size of each granule is 10-14 mm. Its main area of application - concrete preparation.

- Expanded clay sand for dry screed. Necessary in the case, when you want to create a thin screed, expanded clay does not exceed 5 mm.

- Gravel. It allows a very easy, but quite durable floor. There are three categories of dimension and expanded clay granules: 20-40 mm, 10-20 mm, 5-10 mm.

Types of expanded clay under the screed

When choosing a specific backfill should assume, what subfloor device technology will be applied, as well as the room itself, where construction works are carried out.

application conditions

The semi-dry screed floor with expanded clay can only be performed under certain conditions. The most basic - the device thicker screed, which varies within the thickness of 6-10 cm. To begin poured expanded clay layer for planarizing, and only then is poured cement-sand screed.

Also, expanded clay is used, so as not to overlap on the load, especially if it's an old building.  The cost of this material is not high and it is to significantly reduce the costs of all, removing a sufficient amount of cement in solution.

The cost of this material is not high and it is to significantly reduce the costs of all, removing a sufficient amount of cement in solution.

Expanded clay exhibits a huge number of qualities, and the most basic of them - an excellent layer of thermal and sound insulation. As a result, he enjoys enough popular among buyers, beginners in the construction business and professionals.

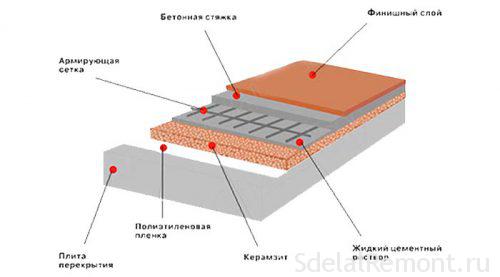

tie layers

Before you get started, should know about, which layers includes polusuhaya screed for underfloor heating. Primarily, this protective layer of waterproofing, which should be combined with the damper band. You can not be afraid to make a greater layer height, since subsequently it will all be cut off after the installation work. After that is filled with expanded clay is not the desired height, invoiced beacons. Embodiments beacons may be different. Everything will depend on the imagination and possibilities.

When all the above is satisfied - pouring performed semi screed, serving as the subfloor. If necessary, it is added reinforcing mesh, which can be replaced by fibrovolokno, popular in recent years due to the large number of positive qualities.

Necessary materials

Needless prepared tool for performing floor screeds indoors. It is very important to buy all the necessary material to work. You can even pre-calculate, which and how many need.

If the room is the size of 5*3 m, i.e 15 m2, the tie layer will be optimal 50 mm. This turns, that all we need to tie 0.75 m3 (square, multiplied by the thickness). When this proportion is usually up sand and cement 1 to 4 (sand 0.6 m3, and cement - 0.15 m3).

The sand will be needed for bedding under the concrete block. If we take the approximate height 20 mm, then released 0.3 m.3. Roughly speaking, at such premises will require almost one ton of sand. Depending on the density of the expanded clay is calculated, and the amount. With an average thickness and in 100 mm, it will take 1.5 m3. This option is suitable for performing a "wet" ties. But not much different and the unit semi-dry screeds, where it is necessary to buy the appropriate mixture with additives.

As for lighthouses, their number, Firstly, It will depend on the rules, its length. With his length and a half meters, on the above premises it will take about five lighthouses throughout the area. The length of such beacons is chosen throughout the width of the room - three meters.

Selection of the expanded clay pellets is focused on, or rather their faction. To calculate everything correctly and independently, enough to open the Calculator for, which can be found on the Internet. Do not be amiss to ask for help in such a case familiar to builders. They prompt the exact amount of material, which must be purchased. It is worth noting, that the materials for underfloor heating screeds do not differ in the number of.

preliminaries

The same preparation is done, for normal execution screed, and for semi-dry. I.e, There is no difference in the, screed dry or semi-dry it will be necessary for flooring flooring. It is important to align the base here, where the work will be carried out. All existing cracks and holes as possible are eliminated by means of cement solution. The protuberances can be knocked down. We can not forget about a waterproofing layer, which can be a conventional polyethylene film. The better the material will be selected, the better quality it will be able to display during operation.

After that is filled with sand, acting as a cushion under the concrete block. Usually it is a layer 20-30 mm. Cushion also be aligned on the level generally and using. As for the ram sand, it can simply walk across the plane. The weight of the person in this case enough.

Selection expanded clay is dependent on the fraction (finely, medium and krupnofraktsionny). He filled up the whole room, from the far corner. After the required backfill layer, should razravnyat. On top of expanded clay mounted beacons, serve the basis for the level of the sub-floor.

As beacons used profiles, which are mounted on the base by means of a cement-sand mortar. In the subsequent screed poured, Several replaces the lighthouse, and they just "hide" in the base of the sub-floor.

Performing a semi-dry screeds

When expanded clay filled, you can choose two options for further action:

- Pouring cement slurry. Installation is performed directly with the solution keramzit. Granules very easily absorb moisture. If this happens after pouring a semi-dry screeds, the drying can occur unevenly, which will lead to shrinkage in area. Some pre-wetted granules in water, and only then carry out the filling. But even this option does not give an absolute guarantee.

- Separation of expanded clay by semi-dry screed waterproofing layer. In podsypku moisture from the solution does not fall, even if just to lay a polyethylene film. the main thing, so it was a whole over the entire surface and was not torn in the process of mounting a semi-dry screeds.

Not everyone knows about, how to make cement milk. To this end, water is used twice as much, than with standard screed. Depending on the result obtained, should watch, if necessary add additional water or cement. In this form,, after filling of expanded clay, necessary to give the present and the litter layer for at least days. Only then can perform concrete pouring semi floor screed.

If beacons removable, they are pulled out only a few days later. The resulting grooves are embedded solution, tamping and carefully polished to obtain a uniform layer.

Expanded clay with a solution

There is also such an embodiment the semi-dry screed, when the solution itself is mixed with expanded clay pellets. This process takes much less time, than in the previous case.

The capacity, which is prepared in advance, poured concrete block, which is filled with water in the required quantity. With stirring was carried out using a mixer. In this dry mixture is poured ready, which should be carefully Stir until smooth. It should be very careful with the amount of water. After all polusuhaya screed it requires a small amount of. Bust lead to the manifestation of negative qualities.

Lumps under agitation should not be any, and granules themselves should become wet and acquire a gray shade. The mixture becomes slightly thick, consistency reminiscent of sour cream.

The finished solution is poured onto the prepared substrate in a thickness 20-25 mm. But the thickness will depend on the flatness of the floor, as well as the final result, which is required for the flooring planks. Reducing the time comes for the reason, there is no need to wait hours, first layer, filled with cement milk, dry and harden.

After the initial layer "cake" is performed to the second and subsequent formation of "rough" floor. During work do not wait until the previous dry layer. Seal coat not only thoroughly compacted, but aligned to the level of.

professional advice

floor screed semi-dry method requires some knowledge and experience of work. Even small nuances will avoid future problems during operation. Some of them:

- When placing the wires on the floor, a future tie, they should be, at least wrapped polyethylene, and attached to the base floor with duct tape.

- To avoid cracks in the poured concrete solution, it is best to add the plasticizer. It will be enough only for semi-dry topcoat ties.

- As floor waterproofing can serve not only as a film of polyethylene, but the asphalt mastic, flashing etc.

- After the screed should be to look beyond the surface. The main event - splash, using a spray bottle.

- screed drying time is about a month. The longer she could stand without external pressure, the more strength will be able to type in the result,. Much will depend on the used floor covering.

- Beacons may make metal rails or special profiles, known as "the flashing".

Compliance screed technology, however it was not, will provide a flat surface sub-floor, to which can be carried out immediately decking flooring.