What is drywall and designation (GKL) any markings used to indicate sheets. Types and edge and core standard size, about this in detail and will peq. Plasterboard sheet called three-layered composite material, consisting of brand gypsum layer T-4, pasted over with the outer sides of sturdy cardboard.

Available in a variety of types of gypsum boards: normal (GKL), fireproof (GKLO), moisture-proof (gypsum plasterboard), moisture-proof and fire-resistant (GKLVO).

Produced for premises conventional and high humidity.

Different in color: gray plasterboard Conventional Premises, drywall for damp rooms has a green color, fire-resistant plasterboard painted in pink.

Knauf plasterboard sheet to increase the strength is reinforced with glass.

Features GCR

GCR is widely used in the manufacture of false ceilings, internal partitions, for walls.

The material is easy to use and requires no special skills and tools.

Standard sizes GCR:

The length of the sheets 2,5 m;

Width 1,2 m;

Thickness 12,5 mm.

standard sheet weight does not exceed 30 kg.

For suspended ceilings apply no more than the thickness of sheets 9,5 mm, the weight of which does not exceed 25 kg.

Detail to calculate the right amount of material for plasterboard walls will help our online calculator.

The main advantages and disadvantages material

Lightweight gypsum board allows you to use them in the houses of the old buildings, without creating unnecessary burdens on the floor.

Plasterboard has increased strength. Each mounting point can withstand loads of up to 12 kg.

The material does not need the use of solutions based on cement and water, which reduces debris, It allows you to perform "dry" assembly.

Plasterboard partitions easier and cheaper than brick walls, block, tile.

FCL is widely used for the manufacture of arch structures.

There is no smell of gypsum boards, they are not electrically conductive, absorb excess moisture and release it at the dry air in the room, able to "breathe".

With the help of gypsum boards are ideal surfaces, do not require additional alignment.

Using cuts of the sheets can obtain different curved shapes, make columns.

The main drawback of gypsum boards, reduced storage space space for frame installation.

Drywall sheets are used for the manufacture of false ceilings, curved clearance surfaces, When zoning space.

Russian construction market offers a variety of gypsum boards from different manufacturers.

The lion's share of the market occupied by the production companies Knauf and Gyproc. Russian firm Knauf Gips is a subsidiary of German company Knauf, and the company Gyproc England.

Gyproc plasterboard brand expensive than its competitor, as it is done in the European Union.

Material under Gyproc mark is mounted on a metal profile Russian manufacturer "Alyumasvet". Caulking recommended material Rigips (England).

Knauf drywall mounted on a metal profile, developed by the specialists of Knauf.

Waterproof sheets of marked letters gypsum plasterboard (gypsum board moisture resistant) and painted in green color.

It recommended for accompanying materials to ensure quality of work when installing drywall, GCR indicated by manufacturers.

Personal skills and tools

Not necessarily have the experience and skills to work with plasterboard. It is important to have a work ethic, assiduity, perseverance.

Of the tools can not do without perforators, screwdriver, plummet, regulations or building level, Shears for metal. Still, you will need a pencil, hammer and knife.

Of supporting materials you will need a metal galvanized profile, screws, dowel-nails, drill.

Build walls and partitions

Familiarity with plasterboard easiest to start with the alignment of walls. This type of work you can do yourself, without the involvement of assistants.

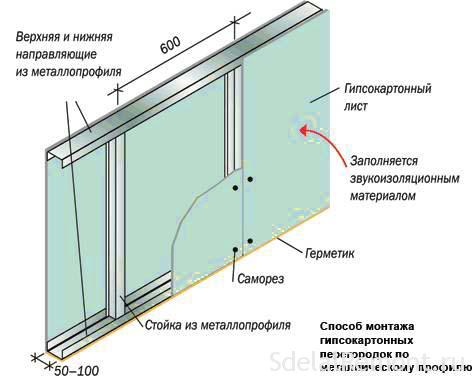

The most important stage, installation frame in galvanized profile. For this we use Knauf technology firm.

The system consists of a metal frame made of galvanized profile, which is sheathed with sheets of drywall.

A few words about the profile

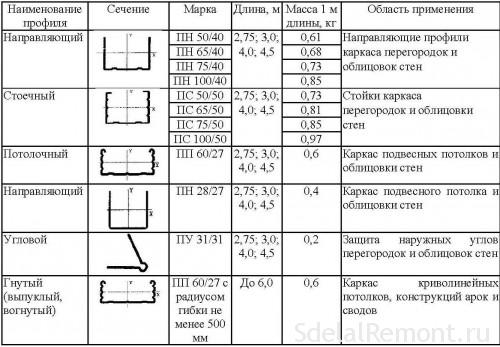

Applies rack profile "PS", section resembling channel. It performs the function of uprights. The size profile of 28 × 27 mm. Import marking rack profile has a CW index.

Guiding profile "PN" section of similar shape acts as a guiding framework for the profile of the "SS" and the bridges between rackmount profiles. Profile dimensions 60 × 27 mm. Marking the western analogue CD.

Corner profile "PU" secures the outer corner joints plasterboards.

Standard profile length is 3,0 and 6,0 m.

For mounting frame required to apply markings on the wall, drilled holes and set anchors. Step drilling selected from 0.4 ... 0.6 m.

The marking is applied depending on the size of gypsum boards employed.

Sheets should be laid on the edges of the middle frame profile.

Before attaching the sheet, make sure to install the required communications: electricity, heating, water, sewerage, etc.. d.

To begin the installation of gypsum boards should be on the wall without openings.

Sheets should be installed in a staggered manner, fastened on the perimeter and in the center.

Attach sheets should screws, Screwing strictly at right angles, maintaining the indentation on the sheet ends 10 ... 15 mm. In this case, be sure to head on utaplivat 1 mm.

As a heat or sound insulation is recommended to use glass wool, cork, izover, Styrofoam, laying between the carrier frame.

When installing drywall on the walls with openings follow the rules: joints sheets are mounted at a distance of 200 ... 300 mm from all corners of the opening.

suspended ceiling

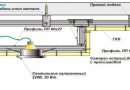

Installation of the ceiling is carried out with the assistant and consists of several stages:

- To mark the ceiling level;

- Apply a horizontal line from the top of the ceiling around the perimeter of the room;

- The horizontal dowels, nails line with a 0.5 ... 0.6 m mounted guide;

- The guide grooves are inserted ceiling profiles, cropped to size;

- Between the axes of the profiles it is recommended to maintain a distance: for moisture-resistant drywall 0,4 m, for ordinary 0,6 m;

- Profiles additionally fastened with fastening suspensions step 0.5 ... 0.6 m.

ABOUT Installation of ceilings in more detail learn and see video. online calculator expects not only the number of sheets of drywall required.

For greater rigidity of the ceiling frame between the longitudinal profiles are established by means of the transverse insertion devices, called "crabs".

Proceed to the headlining sheets of plasterboard with subsequent finish should only after wiring and other works.

Conclusion:

The main advantage of gypsum board is, that in case of failure of any part of the product replacement or repair can be easily performed with his own hands.