Protective roller blinds with a web of metal slats - Blinds - have long become a lifesaver business large and small hands. Installed in the openings of windows and doors, they protect against hacking and unwanted intrusion kiosks, the shops, the first floors of business centers, shopping and entertainment complexes. Facilitate and expedite the lifting or lowering of the web on several openings, do it synchronously, without leaving the premises, even absent in place, It helps electric roller shutter.

The advantages of automated roller shutters

Manual drive allows you to raise or lower the fabric roller blinds due to the inertial mechanism with spring, when the further movement of roller shutters is enough to pull in the right direction, or propeller mechanism - in this case it is necessary to turn the handle.

Manual roller shutter weight management more 35 kg physical work becomes. It is hard to imagine the loss of power and human time, whose duties include maintenance of protective roller shutters on the territory of a shopping and entertainment center. Electric shutters on the windows in this situation - the only right choice. Do not give up the convenience of electric and pampered comfort of the owner of the only blinds.

Remember! If the network is de-energized, It is prohibited from using emergency manual lifting shutters. This is a common cause of damage to the drive mechanism.

What else attracts consumer automatic shutters:

- The user does not need to know the principle of operation of the lifting mechanism of roller shutters and the order of service. Press the corresponding button switch or remote control, and the child will be able to.

- To control the roller shutters do not need to exert physical effort. This is an important advantage considering the actuator, that modern shutters for garage doors and other openings of large area can weigh more 500 kg.

- Opportunity to combine all common network electric roller shutters. Manage the entire protective complex from one location is very convenient.

- The use of radio control enables you to control the distance, a smartphone application - in the absence of hosts on site.

- The control unit all the shutters certain complex can be combined with remote control protection or surveillance equipment room.

- The required height of raising and lowering the blade can be set by adjusting the limit switches. In the extreme positions of the drive will be switched off.

- Possibility of installing automatic lock top structure.

- Electric roller shutters can be integrated into a system of "smart home".

Outs of the electric drive mechanism is attached to the apparatus and the mains, limit the minimum width covers the opening drive dimensions, as well as the high cost of.

selection, installation and connection of the electric drive

Important! Pursuing self-installed electric, the consumer loses the right to guarantee operation of the device, it receives in the performance of work by specialists of profile organizations.

When choosing a particular type of actuator should be considered: the weight of the profile webs, shaft diameter, supply voltage, drive dimensions, rotational speed, power consumption, torque, availability of emergency opening system, possible to build a radio control. Help ease the task of the special selection table, offering manufacturers. Do not be redundant specialist advice of a specialized organization, which not only sets the electric shutters, but also sells drive mechanisms with accessories.

To smooth the acuteness of the financial issue, amuse vanity positive end result, each business user can examine the wiring and cope with the installation of the electric drive alone.

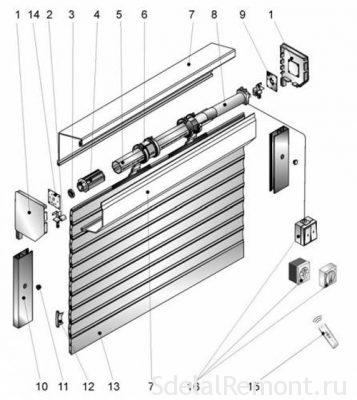

The order of the installation of the electric shutters on the next:

- With box, protects the shaft wound with a cloth blinds, side cover is removed.

- From the shaft disconnected crossbars.

- Freed shaft is removed.

- On the drive adapter fits, then a special cage end position.

- For future fixing the side cover is screwed to the motor mounting strap. Then drilled holes, respective attachment points.

- Motor through a fastening strap is fastened to the side cover box.

- The capsule is inserted with the bearing mounted on the other side of the engine.

- The resulting assembled structure is installed in the octagonal shaft.

- Bearing capsule, located at the other end of the shaft, extends outwardly to the maximum limit position and fixed in the cover. For fixing rivets are used. The shaft and the bearing capsule under these pre-drilled holes corresponding.

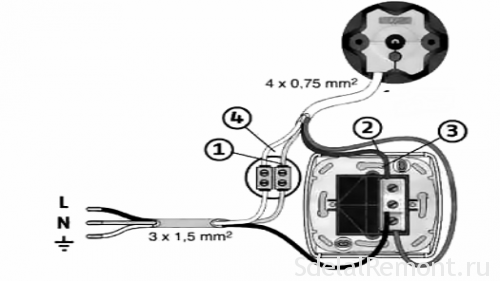

Installing the motor is completed. The next stage - the connection to the mains. four-wire cable, through which the drive is connected to the mains, color-coded:

- yellow-green wire - grounding;

- Blue - Neutral;

- black and brown wires - phase rotation in different directions.

The breaker device is required to provide the phase lock. This prevents simultaneous operation of two opposite rotations.

By means of adjusting "+" screws, "-" on the center pole of the motor response exhibited extreme border limit switches.

Important! Power surges can knock limit switch settings. Periodic debug switch align with survey crossbars blinds.

Featured manufacturers, supplying quality electric roller blind drive mechanisms on the domestic market:

- Somfy (France);

- New, An-motors (China);

- ITSELF, Becker, Elero (Germany);

- Mottura, Nice, Came (Italy).