Progress does not stand still. Advances in manufacturing technology has brought improvements decorative tiles, and now tile had a competitor - tiles of granite. In this tile has its advantages. It has a lower thermal conductivity, It brings great impact precipitation, temperature changes, more resistant to chemicals. Because now we are talking about machining, special attention should be paid to the, that granite has higher strength characteristics. It is much harder to break, make a scratch or scuff on the front side. Therefore stoneware tile has advantage over, when constantly exposed to friction on the feet of visitors or car tires. However, the increase in strength is the question, how and what better to cut granite at home.

It can cope with granite Tile?

Most often, this problem is facing the master, running away, but we are dealing with the matter professionally. In this case it is necessary to take into account only some of the nuances, and you can safely get down to business. Probably, he already has everything or almost everything you need.

If the amount of cutting required is not too big, and the thickness of the ceramic granite tile is not big, pressing question, and whether to cut granite Tile? The answer - yes, it will be possible to manage a familiar tool.

manual tile cutter may be suitable for straight cut. the main thing, that it is of good quality. However, a thicker porcelain tiles or relief can not do without power.

In addition, the increased strength of the material makes it difficult to cut granite and correctly so, that while tile does not burst. Do not get the same cut Tile narrow piece of stoneware tiles wide 3 – 5 cm.

Besides, Tile large size is available. It may simply not fit into the Tile. Or the surface of the tile has a textural irregularities. In such cases, the question arises, and the better to cut stoneware tiles?

angle grinder

first, that comes to mind in this case - this Angle Grinder, or Bulgarian. Any master this tool, probably, are available.

Here it is necessary to clarify, bolgarka that is suitable for medium thickness stoneware: from 5 to 15 millimeters. The best fit for these small works of Bulgarian. This is because, that each cut will be more time-consuming, and hold in their hands a heavy tool is tedious. Besides, a small grinder large speed, but a smaller diameter cutting wheel, so there is less chance of beating and vibration, which may lead to chipping of the cut on the surface when dry cutting granite. As well as a small grinder is easy to hold with one hand. The second hand will be cut off to hold a tile.

Perhaps, the main drawback of this method is, which is quite difficult to produce a perfect cut, but for small undercuts cut granite tiles at home quite succeed.

Since the Bulgarian involves dry cutting granite, the question arises in relation to the diamond wheel. Can I use regular tile blades for dry cutting? Yes, use these circles can, but the amount of chips will be more. The increased strength of the material does not prevent this shortcoming (note, it should be a drive for stoneware tiles, rather than concrete). Moreover, care should be taken to overheat the circle, especially if the thickness of the large granite. It is worth a little overexpose, lead to overheating and deformation range, and excessive vibration. If you cut off the edge will be hidden behind the tiles or other moldings, then the image of chips will not be a big problem. If these surfaces will remain in sight, master's reputation could suffer significantly.

Cutting grinder experienced tilers recommend using the discs for wet cutting granite. Yes, Yes!

When dry cutting of stoneware tiles is better to use circles for wet cutting.

These circles diamond coating has a smaller grain. Because of this, it has a little more pressure on the tool and be more attentive to overheating, but the quality of the cut will be the best, chips will have a much smaller, and cutting width will be smaller.

A method for cutting stoneware tiles next: It will first be necessary to draw a line (prescriber with a tipped or thin marker), then walk along this power tool line, venturing into the tile only 1-2 millimeter. Then repeat extending along the line, each time a little delving. Closer to the edges of the tiles need to be careful, special, if the cut is not conducted at a right angle to the edge of the tiles.

- The advantage is the possibility of cutting grinder cutting even on a curved line.

- The disadvantage - it large amounts of dust during dry cutting granite.

Video how to cut tile grinder dust

jigsaws

Jigsaw - is an indispensable tool in the event, If you need to cut the tiles on a curved line, and the required curves are steep enough. However, to use the jigsaw to cut into the ceramic granite is very difficult, this method is only suitable for ceramic tiles. Naturally, it is used not just an ordinary saw on hardboard, and a special diamond saw blade for jigsaw good quality, because the tile has increased strength. More suitable for cutting stoneware tiles Circular Saw.

Before the implementation of the internal cutting jigsaw you must drill a hole, the diameter of which is slightly greater than the width of the diamond nailfiles. Drilling it must, departing from the cutting line on the inside of a few millimeters longer, so than the drill radius, to give the reserve for possible chips during drilling.

home repairs

For those, who will independently produce cutting stoneware tiles in the home, worth mentioning, it is not so difficult. You need to know some of the features of this work, which pay attention to below, and not be afraid to take on new business for themselves.

To cut granite splinter need to mark the lines cut prescriber or carbide glass cutter. You need to spend some time with this tool for future cutting lines. you will notice, that this line has already occurred chipped upper layer of porcelain, however, the width of this cleavage are very small.

Res produce so, to cutting disc cutting edge was next to his side of the line, and the whole width of the cut is shifted to the other side, that you will not need right now. If you drive on a good grinder, the extra chips are unlikely to form - you get a near perfect cut.

During the cutting of tiles vibrates, therefore it is necessary to fix. The best thing, if the substrate under a tile will be out of the non-solid materials, which will be put out this vibration. Ideal polystyrene foam plate or medium or high density.

highly specialized tools

Of course, cutting methods, which we discussed above, suitable for those, who are not able to shell out a good amount for the purchase of the machine for cutting granite. but, for professional tilers save time for granite cutting operation principle, so the machine will be very to the article. Although the machine can only cut straight, Most cuts it straight. In addition, a good machine will allow to cut granite at different angles.

In addition to a large allowable cutting thickness, at the machine has a number of advantages. First of all, It can be applied wet cutting granite. This method reduces the chance of overheating as the blade, and the occurrence of chipping on porcelain stoneware. Secondly, freed his hands from the weight of the load power. The machine has a platform, which is rigidly fixed to the motor and the cutting edge. Thirdly, the machine has a device for straight forward movement: or tiles, a motor with a cutting tool. This avoids irregularities and significantly improves the quality of cut. It remains only to monitor the flow rate along the guides, while being cut. But the main advantage - it is free of dust when cutting tiles, which is especially important in the repair of the apartment.

Depending on, how often and many masters have to work with tiles, he can think about, What type and size of the cutting machine for granite it will be necessary. For example, if you are working in confined spaces or often, it is more appropriate machines a motor positioned below the operating table. Such machines less overall, lighter and much cheaper compared with machines, having an upper position of the engine (for example, Practice model 1860 It has an average value of 6000 rubles). But such an option greater depth limit cut. Not every model is equipped with a guide for a straight feed tiles and fittings for fixing tiles, which requires certain skills from the masters. Also cut at an angle 45 degrees is not provided in many models.

More opportunities and comfort when cutting granite provide machines with the engine located above the desktop. to master, who specializes in working with tiles, this option will definitely preferable. Although these machines will have large dimensions, They will ensure a safe and comfortable working conditions, a much greater depth of cut (to 100 – 135 millimeters), Some models allow you to not only cut at an angle 45 degrees, but also in the intermediate values. Naturally, this type of machine will have more powerful engines and large diameter cutting diamond wheels. Some of these machines will be fixed, that is to have very large dimensions and weight.

Depending on the manufacturer, equipment, sizes and abilities, Machines with upper motor position have a wide range of prices. Here you can read a detailed overview Tile.

How to remove the chips on the cut edge

Even good artists do not always get the perfect cut. Sometimes the reason - the very structure of the tiles, sometimes - poor quality cutting tool. not important, for some reason you were chipped stoneware tile. If this edge is in sight, there is a need to polish the brink, chamfer or some other way to get rid of this little marriage.

First, a rough layer can be removed by the stone cutting wheel (no diamond), and then a few tenths of a millimeter to bring the grinding diamond wheel, which is called in common bug.

Depending on the grain size, these circles are labeled, like sandpaper. They can not only be sanded, but zapolirovat to perfection your edge. In some cases, eg, if the cut is concave, grinder handle end of the cutting is difficult or impossible. Then the handy sponge Diamond Products. Lightly moisten the surface, circular motion can bring the product to the end or the bevel of high quality.

Gourmets quality and refinement

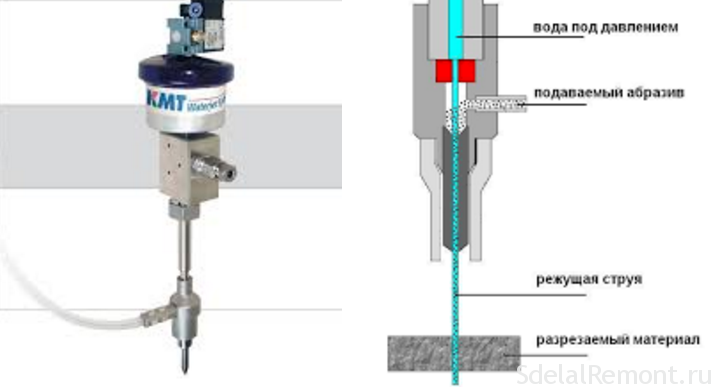

Not a secret, that there is a special category of customers, which can be called a quality gourmet. They are willing to pay big money for it, the work was perfected. Probably, this customer will be difficult to convince, that the hand can be made sufficiently high quality cutting granite. On the revenue can come cutting granite water, or waterjet cutting. This modern technology, allows cutting granite with the highest quality. At home, this is not done, because special equipment is required for it. The main drawback - the high cost of this work, which, probably, will not afford the usual customer.

The thickness at the waterjet cutting can reach several centimeters, in this case the product does not require additional grinding. A great advantage of this method is the ability to cut high complexity, which is not possible with manual methods. And, the difficulty is not only in relation to the figure of the cut line, but the width of the cut parts. Waterjet cutting keamogranita allows you to cut parts at an acute angle to the edge of the tiles, cut thin elements, cut holes and other difficult cuts. This makes it possible to create images, mosaic, panels and other images of granite in different colors. Since rezom controlled by a computer, possible adjustment of mating parts with perfect precision. Really, gourmets will get the desired result.