should perform quality tie for great sex. It begins with it all the dirty work, not only during the overhaul, but also in new. It acts as the upper part of the concrete base, and serves for the flooring of any type of floor covering. It is for this reason, every effort should be, to get the desired result.

designation

Arrange cement floor has its own function. It is important to know, What is the floor screed:

- Creating a flat floor, in that case, when he has no horizontal or there are any defects.

- Apparatus bilayer surface for floor heating systems. The first layer is mounted after the insulation layer, and the second - after laying heating wires.

- floor leveling in the same level in different rooms. Such problems begin to appear after the poor quality of concrete pouring, or of the improper billing level. If you move away from this point, then later it will be impossible to implement quality laying of floor covering. Otherwise, can form the so-called "step".

- Sex should always be to maintain a certain load, have a sufficient level of strength. Here comes to the rescue and screed.

But this is only the minimum and most basic functions, which is able to perform a screed in the apartment. Everything else will depend on the particular situation of its installation.

Composition of the screed

Prior to the beginning of the work should focus on the application of the composition to perform floorings. That is, if we take into account the variations ready mixes. Nothing complicated here is not. The most basic components - cement and sand in certain proportions. They allow to obtain the result, towards which every. It is enough to add a certain amount of water, and strong surface obtained after drying.

Are contained in the mixture components do not take high finance, their low cost. This is the reason they have such popularity and demand.

In the market you can find different types of mixtures, which can perform the claimed function or give the finished solution quality. They are ready for their intended use. The solution is obtained inexpensively forces.

surface preparation

The main purpose of the screed floor - creating a flat surface. It is very important to hold on to the proper level preparatory activities. The substrate must be cleaned from existing waste, dust layer. There will be a great help building cleaner. existing defects ("Ridges", dimples, cracks), They should be eliminated by sealing them churning or.

New screed will have better adhesion to the surface in case, if the latter is treated with a primer layer. In some cases, layers may be even more. If the room is damp and has a high level of humidity, then no harm will arrange waterproofing layer. It will act as a roofing material or other insulating material. Greater efficiency is a thick paste, which can be applied with a brush or roller.

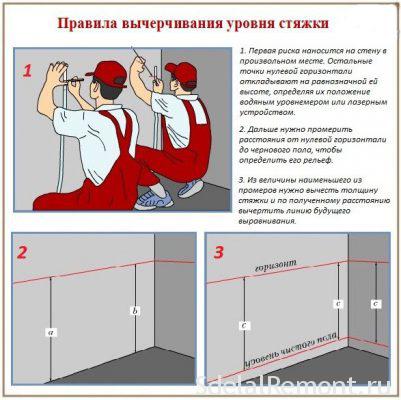

Measurements of the floor

Surface itself must be determined for any distortions. For this fit laser level or other modern appliances. Exhibited zero mark, and also determines the highest point of the base. This will install all possible costs and the amount of work for a solution. With regard to the zero level, it should pierce in each room apartments. He should be in the form of marks in all the rooms, and it is set not by the level of the floor, and on the horizon. If they are connected to each other by one line, then turn the zero level. It can be used for reconciliation with the horizontal all other measurements.

If expanded clay layer is laid under the screed, it is necessary to find possible differences. When working with high quality and compliance with technology, screed installation level will be as accurate as possible.

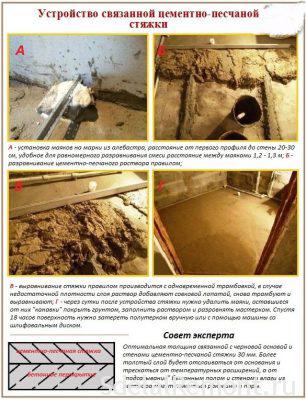

exhibiting lighthouses

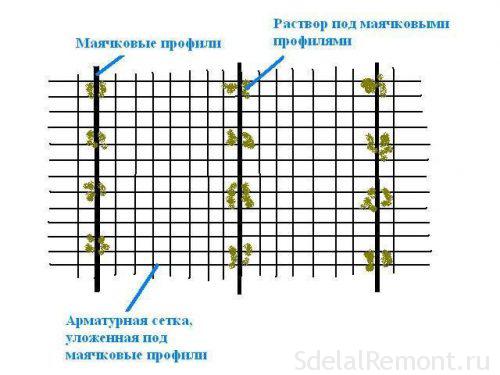

To improve the quality and speed of installation screed, you should set the beacons all over the place. As one of the embodiments may consider mounting the flashing profiles Alabaster. The first of the beacons to be located at one of the selected wall, and the second - in front of the wall. In this case, they must be placed strictly on the level. When a sand cement screed, the number of lighthouses will be a matter of arbitrary.  The more, the accuracy will increase. However, this option is effective for novice builders.

The more, the accuracy will increase. However, this option is effective for novice builders.

the main thing, to the height of the lighthouse was no more than the level of the floor of the future. Step locking elements may vary from 40 to 80 cm. Beacons some tensioned mesh of filaments, to check their horizontality. This creates a certain comfort when leveling of floor space solution.

It is possible to increase strength by ties exhibiting reinforcing elements. This is done until the solution assembly. To fill the grid better suited grout, able to close all the gaps and omissions. Strongly pull it is not necessary, and are evenly distributed over the plane. The sandy floor screed will be more robust and reliable, protected from external influences.

calculation of screed

If the device floor screed is carried out on concrete base, the thickness is generally at least 70 mm. The larger layer is formed on the installation surface of compacted ground - about 120 mm. Some doubt, Do screed floor needed with such high costs of material. A smaller thickness over time begins to crack, since the full will not possess those qualities, which are necessary. Several can be reduced, but not less than 50 mm.

Thick ties to perform better with the use of expanded clay. This applies to the surface at great differences of heights to 200 mm. If this material is mixed with a solution, then we get claydite. In addition, he will receive a great quality, as a high level of sound insulation.

When choosing a pre-mixes, preference should be given to proven companies. Not rare, when caught low quality materials. In this situation, people often perform self-mixing of the solution to meet the requirements of the proportions. In order to perform high quality floor screed with their hands instructions must be respected in any case.

Mixing the solution

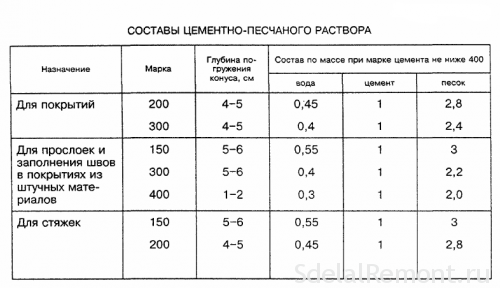

In preparing the solution on their own should pay attention to the recommendations from the experts. Qualitative solution was obtained when the proportion of sand and cement 3 to 1. If you make a proportion of 4 to 1, that such surfaces are more suitable for subsequent laying of tile.

Laminate or linoleum coupler requires using high performance grade solution. In this situation it is very difficult to find quality cement for. Arrangement of cement sand floor screeds involves the use of the brand M400. He finds increasing application in the construction industry. If you pay attention to the brand M500, it should here be approached with some caution, since it is not uncommon for the addition of the various components of the.

Used for floor screed cement and sand, are put into a matched capacity. Then, they are stirred to a homogeneous mass of water and poured. As a result, the solution should be free of lumps, one color, without evidence of clot cement or sand. If this is not achieved, quality floor screed will be poor.

Mounting ties

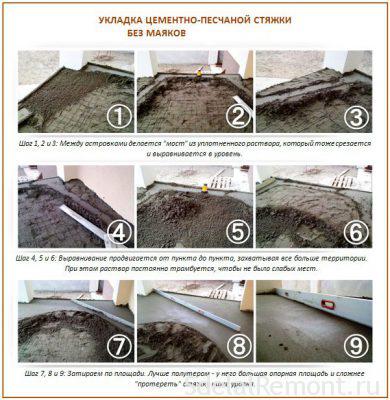

Screed cement sand mortar begins execution from a distant angle from the entrance to the space. It is enough to put it to a height of about two feet, and then distribute to the input direction by the rules. There is no any pitfalls. Easy installation with low cost, and attracts a large number of performers. In addition, experts have learned to carry out the installation without installing beacons.

When installing screed should pay attention to what, to each gap was filled with a solution of. If such and will manifest, they can be filled with a spatula.

To navigate through the floor space of the solution is used generally, which moves according to the established beacons. From this comes, that the distance between a number of beacons placed there should be more, than the length of a rule.

The last thing is done grout those bands, which are located opposite the entrance. I.e, at first everything is done from the side walls and toward the center.

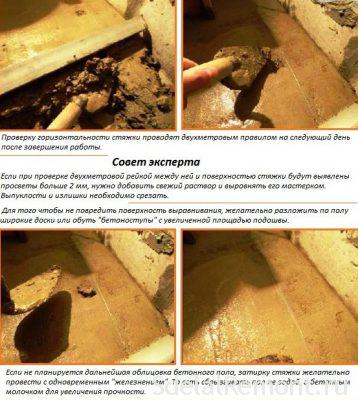

After that, the solution begins to harden, all the bumps formed should bring down with the help of a spatula. wood rasp is used to obtain low surface roughness and uniformity. She erased the entire surface. But also for grouting should be done right solution, the device floor screed with their hands appeared at a decent level.

Using screened sand, mix it with cement in equal proportions. Thereafter, the required amount of water is added. Do not be amiss to wet the surface when working from a spray for a better setting.

Typically the level of the final stages of implementation of the floor screed in the room will help to identify irregularities on the surface, smooth them out and eliminate. The solution should be maintained for at least 12 hours, after which it will be possible to move. But it is impossible to provide him a strong external impact to dry completely, that is to 4 weeks.

Regarding the number of employees, then it all depends on the required speed. While one solution to the base flooded, second leveled his, may third kneading the mixture for subsequent mounting. It is very shorter period of time the use of special equipment in the form of concrete mixers.

Ending

If necessary, After drying the guide surface should be removed (beacons). The formed voids are sealed with a solution of. This will provide a monolithic floor screed.

Depending on the proportions used in the preparation of the solution, as well as the specific recipe, Drying time will be from 10 to 30 days. If time is better to give more time to stand screed, so that excess moisture is gone.

All the moments and installation stages of responding to the question of, Do I need a screed in the apartment. Without it you can not do nothing, if you want to level the surface under the flooring of any kind of floor covering. It is from the latter and will depend on the performance of a specific embodiment of the screed, all the details and the little things in.

floor Pouring cement sand mortar does not take a lot of time and financial costs, but it allows you to subsequently obtain a solid and strong foundation, able to withstand heavy loads from outside.

video selection