For laying any type of flooring should perform high-quality cement-sand screed. It is necessary to align the base. Installation of concrete floors takes some time and work, but it has the minimum cost. All major components may be easily purchased in the market of building materials. It should make all work in strict accordance with pouring technology of cement-sand floors, comprising certain steps.

Embodiments screed

When selecting a specific device type concrete floor, It should start from the fact, how it will affect the base. After all the components together have considerable weight. Everything will depend not only on the quantity of water, but the power coupler. Each tie square meter with a thickness 40 mm will exert pressure on the surface at about 90 kg. That is, depending on the thickness and dividing device will be a cement-sand mortar into types:

- associated option. Perfect device cement floor with a layer of no more than 40 mm. It becomes a single whole with the sub-floor, as well as the walls and other structures in the room. It is very important to spend quality preparations, of which will depend on the strength of the finished fort and variants. All deep cracks and potholes should be filled, debris removed, mounting tabs are bent using a sledgehammer. If there are minor defects of the base, they leave, to better clutched solution after pouring.

minutes later 20 after mixing the cement-sand mortar begins to lose its quality. It was during this time it is best to apply the fill for better quality.

- Not connected to the building structures. When selecting such a variant device of floors on concrete base, adhesion is not important and all, connected with it. But it will require a very smooth surface for the grout. It should in addition have the property of water resistance, so that moisture does not leave the tie, which will dry out. The thickness of the embodiment device is typically 50 mm.

It is impossible in the preparation of concrete floors using different primer and mix for concrete floors, which increase the level of adhesion.

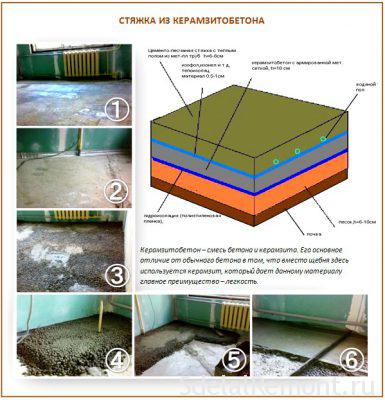

- floating plate, separated from the floor and wall layers. Layer thickness for leveling the floor in such a case is from 50 to 70 mm. From the base of the next solution is separated by means of a waterproofing layer arranged. Also it is separated from the wall by means of the damper tape, made of foamed polystyrene. Reinforced concrete floor to get a quality, if you add a reinforcing metal mesh or fiberglass. In the latter case, almost completely eliminated the probability of occurrence of cracks in the future screed surface due to positive as a component.

Determination of thickness

Thickness future ties It will depend on the prepared base. If this is hard-packed soil, the layer is usually made of solution within 100-120 mm, and when the device according to the concrete base - about 70 mm. You can reach 40-50 mm.

For large differences in elevation in the room, except for the cement-sand screed is not superfluous to use of expanded clay backfill. This will save money and get a better future surface. To get claydite, These components should be mixed together. In addition, the insulation level will be at a decent level.

In such ties, there are some minuses, related device technology. But even in this case, its popularity remains at the highest level. Direct process to avoid errors in the work, if you do everything efficiently and consistently.

In determining the number of calculations for the thickness of the solution used are produced. But not everyone knows about, which mixture is used for leveling concrete floors. The store offers a wide range of. Of particular importance will play a grade of concrete to fill the floor. It will depend on the strength and strength of the finished solution.

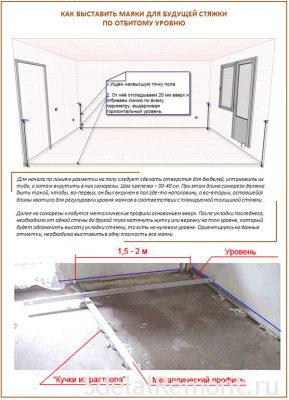

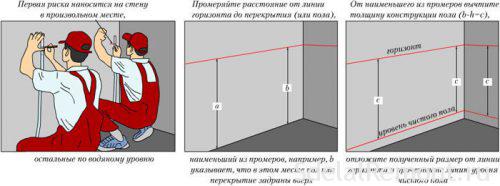

Marking the base

Almost never is an ideal surface for the device cement screed. Consequently, you must set the highest and lowest point. Here assistant perform laser level, giving more accurate results.

The first mark is applied independently at the level of 1 meter of surface, which will subsequently grouted. It will serve as a starting point for a horizontal line. Delineate suitable pencil or chalk. the main thing, to the level of safety to the next measurement. The name she received her - zero.

From the highest point of the room is set in the distance 30 mm in height and a note on the wall. It should also produce the measurement from this point to the zero level. Thereafter carried scribing points down from the horizon. The results are interconnected. It is this line and the plane will be the future ties. On it are exposed lighthouses and other calculations are carried out, respecting the rules of the device of floors.

The choice of lighthouses

For high-quality floor leveling cement-sand screed, should expose beacons. They will provide a smooth surface with minimal effort. For them, you can even take the tube, which is the diameter 15-30 mm. Each builder selects a more suitable result, allowing to obtain the desired result. There is only one main requirement for it - the stiffness and ability to withstand a certain load.

There are several ways, thanks to which you are installing beacons:

Using broken-off line, drilled screws. Their need for each beacon on 3 pieces: on the edges and in the middle. For self-tapping screws tightened thread. But it can and sag, if there is a large distance. To avoid this, set the additional support (bars of wood).

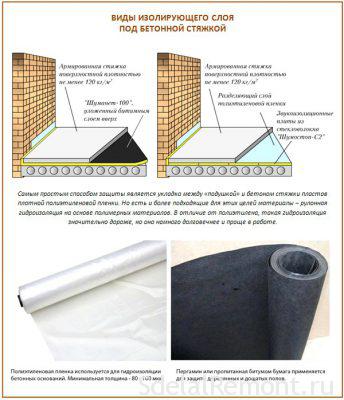

Hydro and thermal insulation

Waterproofing layer can not be ignored when device cement screed. In the most concrete (basis) may be cracked, which are not visible at the time of preparation. They may let in water after casting. To avoid this should apply special formulations and mixtures of the above device layer.

As the sealing material can make:

- obmazochnaya mastic (bitumen, synthetic rubber);

- roll waterproofing, which is pasted over the surface and the walls of a certain height;

- cement-polymer compositions in liquid form.

If it is dry rooms, it is not always necessary to seal all or promazyvat base. Enough to pay attention to the joints of floor slabs. When it comes to bath or toilet, then there is the mixture should be spared to work.

When using roll material, must be at least in the joint 10-15 cm. It is these areas will be the most vulnerable to the negative manifestations. A more expensive option - liquid waterproofing. But the result will please every artist. All these subtleties will provide the answer to, cover than a concrete floor.

When the active layer is arranged, Shading can be performed floor cement. In addition, you can now not worry about, that the water gets to the downstream floors. Pour the cement floor can be on their own, but special attention should be paid namely preparatory activities.

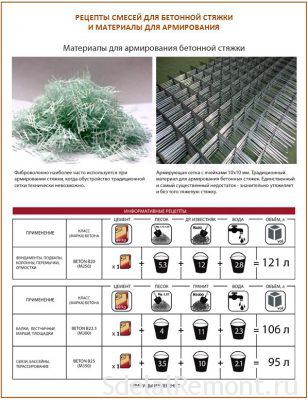

Reinforcement

In the exercise of pouring the concrete floor on the ground prerequisite - the reinforcement layer. The metal mesh may be used as the material, reinforcing bars, or the more modern materials - fibrovolokno.

It is the last component has a large number of properties and qualities, avoiding the appearance of cracks, shrinkage during drying and other adverse manifestations. Especially, if you make calculations on consumption, the cost of fiber will be slightly lower, than for example steel mesh. For each square meter of floor space will require about 600-800 gram of such material.

The use of modern technologies, to align the floor cement mortar, It allows you to significantly reduce the load on the floor plate. This becomes especially relevant in the case, when the screed is arranged in old buildings, as well as the wooden base.

There are several options fiberglass:

- Bazaltovaya. It is used for reinforcement of plaster, lightweight concrete, in the production of press materials, plastic products

- steel. Increased consumption at the expense of weight - 20 to 100 kilograms per square meter, depending on conditions.

- polypropylene.

Mixing the solution

The composition of the concrete floor can be quite different. Everything will depend on the components, are selected Mixing. It is necessary to know and understand, a mixture of Line floor, to get quality coverage. You can pour the cement floor as soon as possible, but the main technology to comply.

There are several options, by which one can prepare a solution of:

- Buy ready-made bags with a mixture of, which should only add the necessary amount of water. But it is worth noting, Such bags will cost a bit more, rather than prepare it yourself, Using respective components.

The leveling floor screed mixture will depend upon the brand of cement. It is best to choose a minimum of M400, to the fortress was the highest.

The leveling floor screed mixture will depend upon the brand of cement. It is best to choose a minimum of M400, to the fortress was the highest. - Check the solution in the mixer. In addition to quality, happy customer and reasonable cost. true, very difficult to bring to site solution from the mixer, special, if a large area of the room. You can use concrete pump for a certain value. This will reduce labor costs.

- Using recipe for mixing a solution of, between a cement mix, sand. You can be further used additives, such as reinforcer for concrete floors. This will be the budget option for leveling the floor fill.

If the cement-sand mixture turned gray tinge, you can be sure, that the quality is high. All other colors - red, yellow, to the contrary. The color of the plasticizers can influence, to better solidify after pouring the solution.

fill

There should be no problems with the, how to pour cement floor. This process takes a minimum amount of time, if all successively executed according to the technology. The beginning of all work carried out on the opposite corner from the entrance to the room. There is poured certain amount of the prepared solution, after which it is leveled by means of regulations in the upstream direction. All slots in this must be completely filled.

Originally populated strip between beacons, located along the side walls, and only after that - the central portions. When all done, solution should be left to solidify. When will the seizure of the solution, guides removed, and the appeared emptiness filled repair pastes.

Any bumps formed should be knocked in using a metal spatula. Thereafter, a floating wooden float. The surface should be smooth and with little roughness.

Term of drying floor after pouring is generally from 10 to 30 day.

During operation, you should know some of the subtleties, Related topics, cover than a concrete floor, not to pylil, as well as the alignment is carried out by grinding the floor.

There should be no problems with the, why sex casting. It allows you to create favorable conditions for the subsequent laying of any kind of floor covering. But even in this case, it should be understood, how to align the concrete floor.