Under a variety of different floor coverings embodiment serves concrete leveling floor screed. This is due to a very simple installation, long service life and excellent display the qualities. Sex then becomes smooth, suitable for subsequent floor screed in the apartment. All possible defects with a solution eliminated. It is worth paying attention to, that in the case, when there is a floor screed device technology should be observed without deviation. Only in this case can get a firm foundation.

notion

Under a concrete screed mean base, acting as a surface for any type of floor covering. To carry out the installation of a variety of ways, which differ depending on the situation.

Screed is necessary not only to, to align the base, smooth all the existing defects, create a surface with a uniform load distribution, but also enhance the strength of the floor. Since the liquid solution used in the process of mounting, such a screed called "wet".

It is very important to correctly and carefully approach the choice for the mixture. After all, not everyone knows, how to make a concrete floor. Do not be amiss to refer to specialists. All will depend on the amount and quality of the desired. In addition, the concrete floor with their hands does not require special knowledge for installation. So that the mixture will play its role.

Each package out of the mixture contains all proportion for mixing, as well as recommendations from the manufacturer. It is enough to read them, explore and start fulfilling.

classification ties

Types and kinds of concrete screeds there are so many. Should choose to focus on the most basic of them:

- related. The kneaded mixture is poured directly on the substrate, which had been primed with deep penetration. Coupling is maximized, and subsequently such a surface will be able to withstand heavy loads.

- With a layer of insulation. It is necessary to obtain a floor with high. Among variants isolated Heated floor (to reflect and retain heat inside the room. Screed still has the name "floating", has excellent quality sound and heat insulation. true, strength somewhat lower, than other analogs. Under environmental stress destruction can occur.

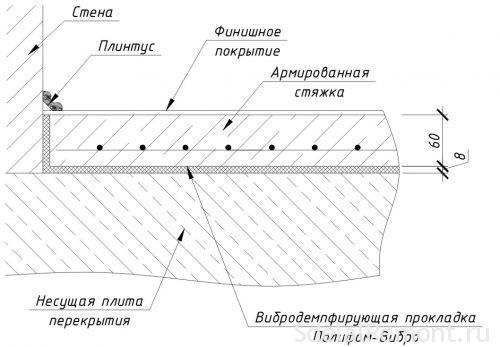

- With a separating layer. Floor screed arranged only on top of the waterproofing layer. There are materials roller, painting materials. There are requirements on the level of thickness, which should not be less than 3 cm. Strength is also reduced, but waterproofing properties delight.

With regard to strengthening the concrete floor screed, the two methods is isolated:

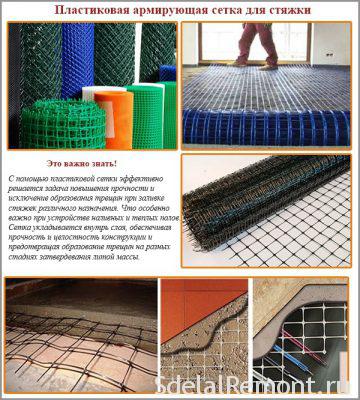

- Adding fiberglass. The surface quality is higher, and the installation takes much less time because of your component, which is added to the solution when mixing. In addition, the tie becomes more pliable, which contributes to its uniform distribution across the surface when pouring. Cracks almost never appear after drying, important to observe all the stages and sequence of the implementation of the floor screed technology for concrete base. Moreover, the cost is significantly reduced due to the application of fiberglass. Reinforcing mesh extends from the pocket of the order 1.5-2.0 u.e. for each square meter. But fiber - just 0.2-0.3 u.e. It is important to adhere to the requirements on the number of adding a component in solution. When rendering the concrete will krohkim.

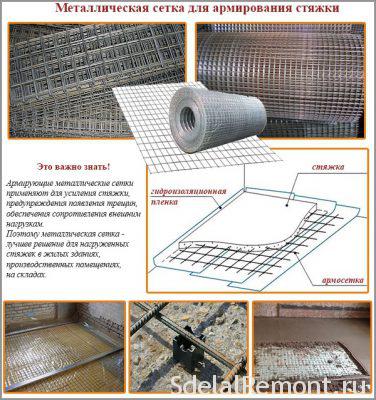

- With the use of a reinforcing grid. It is very popular among the performers. The grid cells are usually taken within 40-50 mm. Stacking is not on the base itself, and the exposed struts, which can act as pieces of wood. In addition to positive features may be encountered and the shortcomings of using such material for strengthening concrete screed. During shrinkage cracks may remain, despite the presence of the grid. With used metal begins to oxidize over time, corrode, collapse. Performance at this reduced.

Substrate preparation

Now we have to focus on the technology of concrete floor screed in the apartment. The first step is to define the terms and conditions, under which the installation of. Consider embodiment subgrade.

If there is no basement or a basement room, you need to select the soil to a depth of about 50 cm. After that, the inside is filled with sand ("pillow") layer in 10 cm. Necessarily at the same ramming. Next poured gravel. At a thickness of about 20 see is pouring concrete along with expanded clay. It is necessary to create a specific temperature on the surface.

When everything freezes, Getting waterproofing. There can buy a roofing material or plastic film of suitable thickness. Material should anyone enter several Wall, fill layer above solution.

When performing mounting on top of an existing screed, who has already served his sentence, it should be removed to the maximum. The reason for this are as follows:

- No old surface can not guarantee the quality and integrity of. delamination occurs, potreskivanie or deformation. All this will affect in the future on the drenched tie.

- Should adhere to the permissible loads on the floor slab, that is especially true for older buildings. There are parameters of the dynamic and static load. In the first case it is within the 150 kg, Second - 350-400 per square meter. If the screed concrete is performed on the thickness of 50 mm, then its weight will be 100 kg per one meter2.

- The strong rise in the floor will reduce the distance to the ceiling. But it is so slight, to lose precious centimeters.

When dismantling the old ties should be careful, to overlap remains intact. The paper used is a device for tightening of floors, as the punch. After that you should spend cleaning the old concrete fragments, debris and other elements, unrelated to work.

For related ties should clean out the recesses, to cut a crack at least 5 mm, that in the subsequent concrete solution could no obstacles to get them.

All other options screed requires an initial repair base. Voids under waterproofing layer should not be. Otherwise they will become a place of condensate accumulation. For the elimination of defects using trained repair composition. If there are too many, they have a significant amount of, the fit and foam.

After that, the mandatory use primer coating base.  Slabs get rid of dust, increases the adhesion level. In addition, she moisture will not actively absorbed from the solution. This item of preparatory activities is very important. primer distribution across the surface is carried out using a roller. If there are hard to reach areas, it will brush. Compensate for the expansion of the concrete screed allow damper tape, which is placed around the perimeter of the room. If you fulfill all these items, then no one would question arises, how to make a concrete floor with his hands.

Slabs get rid of dust, increases the adhesion level. In addition, she moisture will not actively absorbed from the solution. This item of preparatory activities is very important. primer distribution across the surface is carried out using a roller. If there are hard to reach areas, it will brush. Compensate for the expansion of the concrete screed allow damper tape, which is placed around the perimeter of the room. If you fulfill all these items, then no one would question arises, how to make a concrete floor with his hands.

installation beacons

Concrete floor screed must have a level surface after drying. This helps to achieve installation beacons. They will help produce high-quality leveling of the surface of the solution.

Simplification of operation involves the use of laser leveling. Simply will define a basic level, from which will be carried out calculations. Instead, a cheaper option - the water level. Since it must be carried out in the following sequence:

- Determine the highest angle indoors, where the wall is an arbitrary mark on it (for example - and a half meters from the floor).

- Similar mark by the level are put on the walls of the whole house. Subsequently they are connected to each other via line.

- From the baseline measurements are made to the level of the floor in the room. The optimum distance between them- 50 cm. the main thing, arranged vertically to the strip.

The minimum distance from the soundings to the floor - the highest station on the basis of. Is subtracted from it a layer of screed, its thickness. Usually this option is taken in the range 30 mm. All will depend on the surface and the desired result. In this way, We get zero mark, which should be connected to each other. All calculations are from the baseline.

there are cases, when the whole house can be portions of a height greater than zero. To avoid this, it is necessary to pull the thread from one end to the other and to establish such irregularities. If they, We have to shift the zero level at a certain distance.

From the zero level are installing beacons. They can be as metal profiles, were called Beacon, able to arrange a full concrete floor apartment. During operation rule in leveling solution, they can withstand a given load. Besides, popular self-tapping screws, which are screwed on the area in the room. To the extreme of the lighthouse from the wall should be maintained at a distance 25-30 cm.

From zero marks stretched fishing line, that there are no sagging. In certain places is a hole in the ground, where it is driven into the dowel and screw screwed to the set value. Its upper cap must keep pace with the zero level. On top of the caps screws tightened cord. Step installation of beacons by the device under floor screed is 35-40 cm. If in a subsequent beacon will remain in the screed, instead of the cord will be optimally used wire. This will create a kind of an additional layer of reinforcement.

subtleties reinforcement

In the implementation of the concrete floor screed there are many nuances, with which to be reckoned with. This is especially true when thick layer implementation solution reinforcement. When the location of the metal grid with cells in 50-100 mm, there is a lot of mistakes, when fresh concrete floors. Do not place the grid directly on the floor or further layers arranged waterproofing. To benefit from the reinforcement was, material should ideally be located in the middle of the cast solution layer. Not everyone knows in this case,, how to make a concrete floor. The shops are commercially available special supports made of polymers. The height may be set independently or acquired an option. Here it is necessary to do without wooden props. The reinforcement should be to install beacons and location.

Mixing the solution

At present, very few people make their own batch of cement and sand for solution. It takes time, and it is not always exactly the proportions are respected. Replaced by ready-mixes. Just add the required amount of water according to the instructions from the manufacturer. If done efficiently and correctly, the result will please everyone.

Somebody think, the more cement into solution add, the higher the quality of the concrete outlet. But it is a serious mistake, since after drying, the solution begins to crack, spill, crumble. Strength gain, he could not because of the small amount of water. All standards should be reflected in the fact.

With self-preparing a mixture, all components are mixed until a homogeneous mass, and then added to the desired amount of water. For every 5 kg pour the resultant mixture should be approximately 1 litere of water. floor concrete screed technology must be respected at every stage, especially when it concerns the use of mechanized equipment (concrete mixer). Moreover in this case it turns halfway more durable solution, than when using a shovel or improvised.

Do not be amiss to use assistant, kneading solution that will at that time, when the other starts to pour the solution and distributing it over the surface.

Mounting ties

If you need to perform concrete floors installation is very simple with no serious knowledge. But it is necessary to pay attention to the correct implementation of all preparatory activities. They determine the quality of the subsequent. You can highlight certain subtleties, which must adhere to each performer:

- The optimal room temperature 15-25 degrees. You can work and +5, but in this case the rise time for concrete maturation. To avoid cracks, should abandon mounting at higher temperatures. The upper layer will start to dry out significantly faster.

- When the device floor screed according to the technology in the apartment, involved in the work of assistants. They will allow to prepare a solution in the implementation of the fill, to avoid its premature drying.

- The beginning of works - from the far corner of the room to the entrance. For uniformity ties and its strength is necessary to produce work for a maximum period of time compressed, meet on the same day.

- Pay attention to, not to leave voids, where there is no solution. They are buried with a trowel. All air bubbles out of the solution should come out. This will help "shtykovanie" with a shovel or trowel.

- It will only have to spend on the guide rule (beacons), distributing the solution uniformly over the entire surface. Surpluses can be easily remove by the end of the room, where the wire mounting.

Apparatus concrete screed

If done efficiently and perform screed, technology will give a positive result. subsequently,, after drying, You can produce any type of laying a floor covering.

Tips from the expert

All of the following types of work can not start earlier than two weeks after potting. Recommendations for complete drying prescribed on the package from the mixture. It is impossible to resort to early drying. That concrete water and adhesion to the base is the key. It is possible to periodically wet the surface, if you are seen premature drying. For this fit the wetted roller or spray gun. No drafts and mechanical effects on the screed to dry and should not be.