How to choose a heavy, convenient, but not a big puncher with a cartridge SDS MAX (SDS MAX)? It would seem that, reigns in Europe crisis, production stagnation, buyers poured cold. However, most manufacturers of big names continue to increase momentum and produce large-sized tools. Particular attention is paid by such companies jackhammers and electric hammer as the one of the most sought-after in the construction market. We have already told how pick hammer home. TEPER we pick heavy hammer SDS MAX following companies - manufacturers - Makita (Makita), DeWALT, HITACHI (Hitachi), Hilti, TIME.

Significantly, that the production of building materials giant, with years of experience - the company the METABO - only recently approved the release of heavy shock art as evident promising area. Not far behind and the company DeWalt, It is widely known for the production of high-quality woodworking tools, offering customers drills and jackhammers. The high rate of return on sale shock art achieved, Firstly, rather expensive servicing, and not the margins. Due to the enormous load level, which are tools, parts and mechanisms wear out fairly quickly, requiring replacement and reconstruction.

Design features heavy rotary and demolition hammers

The question of choice of fastening systems in percussion, in particular, chisels and drills, long-shot. To date, almost all manufacturers have preferred SDS MAX system due to the exceptional wear resistance of parts, resistance to overloads, as well as to the damaging effects of vibration. Such unanimity in the ranks of the producers found a positive response among consumers, tk. It has the opportunity to choose consumables, focusing not only on the specific manufacturers, but also within the desired price range.

Wherein, as known, miser pays twice, and the consumer, wanting to save, often forgets, that jackhammers and drills, are extremely high impact energy, They can not be equipped with inexpensive consumables. Take the example of two punch with impact force 12 George and 27 J. (DWT BH-1500 with a capacity of BMC 1500 W and AEG PN 11 with power 1700 W respectively). In both cases, the impact energy while the tool is quite enough, to flatten the shank drill low quality and low price without the possibility of self recovery. However, builders are quite entitled to pay for a replacement Drum Barrel, which will cost a pretty penny. count up: item worth a few hundred dollars, cost recovery of the gun and replacement parts are not counted in the tens of rubles. It is easy to calculate the amount of the overpayment.

As known, requirements for European producers of percussion instruments is several times higher, than the requirements in our country. Our products are simply not subject to rigorous quality control for export abroad: are present electrical interference, affecting the quality of the work, high noise level and vibrations unacceptable level - unfortunately, framework, which have become the norm for European producers, for our producers are kind Procrustean bed. Squeeze it until there is no way. In particular, foreign production equipment is now equipped with anti-vibration handles and knobs against depreciation, significantly reducing the harm, the damage to the builders during operation.

Makita - a well-established company in the field of production of percussion instruments - a long time produced a punch model HR5001C SDS-MAX without significant design changes, that, by the way, It was not necessary. Puncher fully meet the requirements of the time: a high level of endurance, durability and operability together with the engine power 1500 W, good impact strength 17, 5 J., weight 10 kg and cost slightly less 20 thousand. rubles. This tool allows us to call one of the best in its niche SDS MAX and price category.

but, due to the need to comply safety requirements, MAKITA produces VTS MAX perforator HR5210C with identical specifications, but with enhanced features for safety, Firstly, reducing vibration during operation (This additional protection was called AVT): dynamic counterweight (It compensates for vibration due to piston protivohoda), anti-vibration handle and amortization lining. Impeccably fit into European standards, tool, true, It gained half a kilogram in weight and 4 thousand rubles in price. However, representatives of companies from European countries counted, that the spending on the improvement of percussion instruments in the framework of safety in times less spending on treatment of victims of the same tools, but created without observance of strict rules.

It is becoming increasingly popular among manufacturers acquires liquid lubricant mechanisms severe shock art. There are a quite plausible explanation: liquid lubricant, in contrast to the usual, thickens in the cold rather slowly, quickly distributed over the tool mechanism, protecting from heat reducer, and this extends the life of the gun or hammer.

housing - Another important detail, which is directly proportional to the quality of protection provided by. Corps of quality plastic saves not only the metal parts of the machine, but also its operator from burns, reduces vibration, an insulator from exposure to electrical current.

The notion, that the punch housing during operation should not be heated - mistakenly. However, there is a certain temperature limit of its heating, which are designed to maintain lubrication, ventilation and metal housing, heat dissipation and cooling tool. Otherwise, there is a risk not only burns, but also reducing tool life. Cooling also serves as an elongated handle, which is a complete set of hammers, eg, company's DeWALT. Besides, handle - a very useful and convenient item for those builders, which often are working on a horizontal surface.

Concerning complete heavy shock art, the best in terms of profitable option: buy the gun or hammer in a special suitcase, necessary for the storage and safe and convenient tool transport, and with a maximum of one chisel. It's simple: often manufacturers equip the instrument with unnecessary details and drills, that, ultimately, unlikely to be useful. therefore, advice for saving: procure the necessary minimum, picking up later on their own the rest of the necessary elements.

Another firm, kings in addition to the above production percussion, is HILTI, the principle of which reads as follows: implementation of direct sales exclusively produced equipment, bypassing suppliers. It is often fraught with complications for buyers of small settlements, related to the issue of repair and service. On the other hand, There are numerous laudatory reviews about the company on the part of a great number of customers and unique warranty period and service: The elimination of any damage within 2 years old. It remains to solve small problems: how to get to residents of remote villages to authorized service center,, certainly, to resolve the issue with the price. The cost of these miracle machines reaches 98, 5 thousand (like HILTI TE 70). This kind of record. And at the same time, for the same price you can buy 4 punch BOSCH, spare parts to find that much simpler.

tool selection when buying in the first place depends on the features, which will mostly be used. For the destruction of any design has obvious advantages hammer due to the fact, that his performance in the direct impact mode is several times higher, than that of the punch of the same class.

How to choose a versatile heavy punchers SDS MAX

not infrequently, because of the high cost of tools, the question arises: it is more profitable to take - hammer or hammer. And more profitable in terms of cost, and tool versatility. When, if there was such confusion, the choice is clear: drill.

Heavy hammers are conventionally divided into 3 main, based on their weight:

- weight of not more than 5 kg;

- weight of not more than 7 kg;

- weight 11 kg or more.

Hammers middle weight category are not inferior in functionality heavy punchers, significant differences in the price. Their main functionality is wide enough: installation of split systems, drilling of wall openings and pipe-laying and wiring. Undeniable plus 7-kilogram instrument also drills the possibility of using for light rotary hammers through adapter SDS +. This option will significantly save money.

For, To simplify the choice Drifters, compare the most popular brands with parameters approximately equal, in the same weight class (except for the last) and the terms of the warranty service. It will be drills Makita HR4011C, DeWALT D 25600 K, HITACHI DH40MRY, Hilti TE 76-АТС, AEG PN 11 E (heavy punch).

Perforator Makita HR4011C

Quite a new model of the Japanese company, allowing not only punch, whose diameter does not exceed 45 mm, but also to use the hollow drill bits with a diameter 105 mm. instrument the impact energy - 9,5 J., engine power - 1100 W, the result of these characteristics is the extremely high level of performance.

In keeping with all the stringent safety criteria, punch has a number of features, that it should be noted separately. Firstly, This increased wear resistance of the metal gear by covering the last of metal and plastic housing. Besides, of course, puncher fitted with protection against vibration and the unique automatic display system of the electric cable is damaged or worn carbon brushes. tool weight: 6,3 kg, price - 18,3 thousand rubles to the manufacturer's guarantee to 1 of the year.

Perforator DeWALT D 25600 K

The uniqueness of the instrument in the presence of a specially designed plastic gear housing, which does not need to be removed when passing service, that at times reduces the process. Thanks to this successful innovation has increased the ability of the body to remove heat during operation, cooling tool, as well as facilitating access to carbon brushes. Besides, Hammer is equipped with comfortable extra long handle, which can be attached to the back of the. The power and energy of the impact of such an instrument: 1150 and W 10 J. respectively. Minus a small system is the lack of AVT system, which is not fully compensated by the depreciation linings. Also, is there a display system, allowing time to identify and eliminate the wear or breakage.

Like the previous contestant, tool allows you to make holes with a diameter in the area 45 mm. Its weight - 6,8 kg, and the cost - 19,5 thousand. However, for this price (in case of contact action, of course) we get together with the hammer sander DeWALT D 28942 (power 2,2 kW, circle diameter 230 mm) in one large suitcase. In the free market buying such a gift will cost 5,5 thousand.

Perforator HITACHI DH40MRY

This tool stands out among fellow body design, but otherwise similar to the previously discussed. With engine power of not more than 950 W, Hammer shows impact energy 10,5 J.. Also of interest is the high level of engine protection against ingress of small construction waste during operation. Talking about the Protection, we should also mention the presence of anti-vibration system of the same brand. Also, the tool boasts a high rate of beats : to 2650 per minute, which it is associated with the electronic engine speed control: maximum 480 rpm. openings, which can give the punch to be a maximum 40 mm in diameter, using this parameter hollow drill bits increases to 105 mm. The price of such a miracle - 16, 5 thousand Russian rubles.

Hilti TE model of big punchers 76 ATS

Already the only one among the hammers mentioned above will cost 45 thousand. In exchange, you get: high motor capacity 1400 W, giving the impact energy to 8, 3 J.; drilling diameter - 40 mm, with hollow crowns - 150 mm maximum. Besides: improved operator safety in case of a possible seizure of the drill, provided that the presence of an active torque control system. Also included - level indicator of wear of carbon brushes, power switch mode and system of protection against vibration in the form of anti-vibration handle.

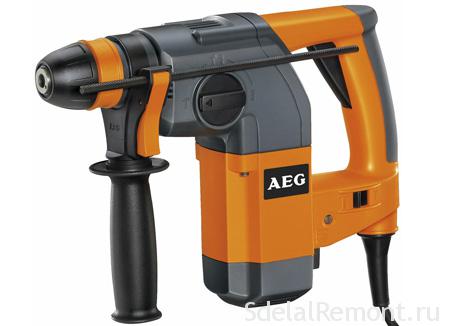

AEG model heavy punch PN 11 E SDS MAX

Due weight in 11, 8 kg hammer falls into the category of heavy. The rating he got with a view, to visualize the difference between the punches of different weight categories.

This punch made in Germany - new model. it is distinguished by, Firstly, linear motor setting, in connection with which it is ideal for operation in the horizontal plane or to produce a sufficiently narrow space. With stunning performance due to high power engine (1700 W) and, Consequently, devastating impact energy - 27 J.. The cost of such a king - 26,5 thousand. The conclusion of such a comparison can be made: having an acceptable price, its characteristics and parameters shown it significantly exceeds the average weight category Hammers.

findings.

Verdict: each heavy puncher there are pluses, and cons, However, under the initially set parameters (small construction team) best suited DeWALT D 25600 K, because:

- angle grinder in addition superfluous in any way will not be;

- ease, convenience and excellent technical parameters, as that: engine power and impact energy, isolated perforator advantageous among other;

- the quality of products by DeWALT is no doubt;

- the company's level of service over the past few years only increased, causing multiple positive feedback, Besides: nice variety of promotions and bonuses served their purpose for the good reputation.

In the end,, the information presented is based on a purely personal experience and is only exploratory in nature. Everyone is free to pick and choose the tool, based on their own perceptions of the quality of, safe and adequate service.

Especially for site apartment repair.