Today it is hard to imagine any repairs and construction work without the use of foam. And in each case, it will be important to use not only the proposed solutions on the basis of a cylinder and pipes available to it, but to resort to the use of foam, applying gun. And then the question arises - Gun foam - which one is better to choose. For this matter is taken seriously, because the use of the gun will greatly simplify the work at height and will allow more quality work foaming seams and formed circuit.

Features and benefits of the use of technical

it is important to decide what it will be needed and what are the benefits before using for foam gun will in carrying out this type of work. If we are talking about one-time foaming space between the windows or doors, it is not necessary to purchase a gun and will be sufficient to apply the proposed set of tubing and bottle with foam. But if the frequency of ongoing installation work is carried out more than once, the use of the gun will provide much better performance and create slopes of the criteria for its application.

And here is to provide a number of advantages, which will provide a familiar and less familiar to all gun foam, namely:

- economy. Achieved by the uniform distribution of foam and detailed supply pressure. This has the advantage 3 fold, not allowing the sprayed excess quantity of foam on the weld surface area or, when you install any of the elements in an existing opening.

- Usability and performance improvements. When using the gun, you can improve the performance of the installation. Creating best criteria for the foam movement and a detailed approach to the process. It can be more easily extrude the foam and fill the seam space is, rather than parts of the walls or elements of the product.

- The relevance of a detailed and sealing of narrow spaces. can be approached in more detail With the gun applied to the foam flow and enter it even in the most difficult accessible places.

- Repeated use of the foam cylinder. When used properly, the gun. You can use the remaining foam again, that can not be performed, if you take a foam tank.

These criteria make it possible to apply a foam gun, taking into account the specificity of certain volumes and joints or existing space for foaming. It is worth noting, that such a device will allow universal approach to work and to avoid significant marriage in places docking of individual products.

Design features of the tool

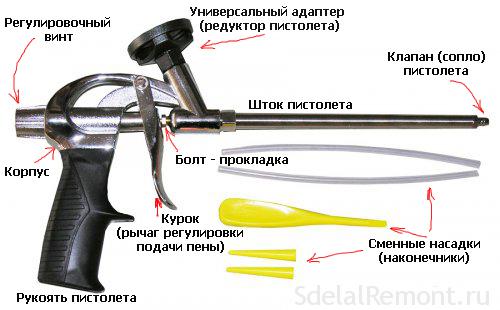

Before selecting a tool for the construction work it is important to detail the approach to the study of its structural features. This would eliminate the choice is not high quality and the right solution for each of the cases. and in the case of a gun for foam. Each gun has its individual elements, namely:

- housing. This element may be formed, both from metal, so plastic;

- metal barrel, It allows you to create a concentrated stream of foam and it is located within the needle rod;

- Lever. To the surface of the trigger, which drives the exhaust valve;

- Tip. Due to the selection of the profile element can be selected and the amount of sprayed foam;

- Adapter. Its special feature is the cylinder fixing with foam and possible submission to the gun system. In this case, the adapter (reducer) there is a valve, controlling foam portions movement;

- adjusting screw. This element allows you to control the movement of the hammer and power, which enters the foam in the gun barrel.

Rules for applying foam gun

When used correctly, any construction tool, you can talk about his durability. In this case, the gun foam is no exception and given the yard of the rules and abide by them, the mono will talk about the continuing use of corruptible in its construction and assembly works. It is important to take into account the safety of the, because foam, located in the cylinder easily, flammable and in contact with skin or opening areas of the body can cause irritation. Therefore it is necessary to take into account the rules of the yard, namely:

- Before using a new bottle with foam, it is necessary to thoroughly shake. Then vertically upper valve screwed to the gun. Then flipped the gun into the operating position, and the work is carried out with a strong girth pistol grip.

- Surface, which will be applied foam should be cleaned of debris and dirt. It is best not to apply foam at a high temperature, as this may affect the curing process with a heated surface.

- Increasing foam flow rate should be, due to tightening the screws controlling, but not at the expense of a stronger trigger pull. It should be understood, that the pressure generated by the foam will quickly go, should prepare for this volume and space for foam distribution. This will prevent loss of material and low-quality execution of work.

- All work carried out should be carried out in gloves, and the presence of workwear, It will protect the exposed areas, Foam misses to the skin. It does not in any case impossible to remove excess foam hands, so you should use a cloth or a spatula.

- Perform work on the foaming space, stands top down, to be able to control the placement and distribution of the foam in the joints evenly. It also allows you to see the result of foaming during the movement of the gun nozzle.

- To clean the gun after performing works, necessary to use a special tool. This will allow to leave the device in operation, even after long periods during the foaming and lack of work.

- In the process of lack of work or minimum break, should leave the bottle upright, avoiding direct sunlight.

- When reusing the container and foam residues, should resort to washing foam supply portion and, This will prevent jamming of the container and give a reason to use the material completely.

When storing is unnecessary to remove a balloon, This tool allows you to keep in working order for many months.

Major selection criteria for gun foam

The most important criteria for the selection of equipment is its reliability. From this point will depend on the workflow, and practical application of the criteria. It's worth to pay attention to the choice of products. And here it is necessary to give the preference to methodological articles, which will not only ensure the integrity, but the best process of moving the foam, without corroding the main elements of the product.

Also worth noting, and the place with the selection of a light gun, which will allow less tired hands and perform a large amount of work does not rub the calluses and more reliable to stay in the hand. Giving reason to perform any practical volume. in addition, watch the video at the choice of the mounting foam gun.