- Methods of finishing the house

- How is lined with gas concretes?

- Methods of attachment of bricks

- whether the gain is required openings?

- Fixing with pins

- The use of flexible connections

- Communication from Armplast

- Variants of the company Glen

- Flexible connection ZV-Welle

- Recommendations for use

- The use of masonry grids

- How to lay tile, brick above the window

Foam block does not look very attractive and needs to be protected from external influences, for this is good facing brick. However, many question, as an attachment to the facing brick foam block without wounding derived mortgages, it is quite possible. To do this, there are certain home-made and ready-made solutions which are and will cover in this article, and thanks to the photos and videos you can handle with your hands lined with houses.

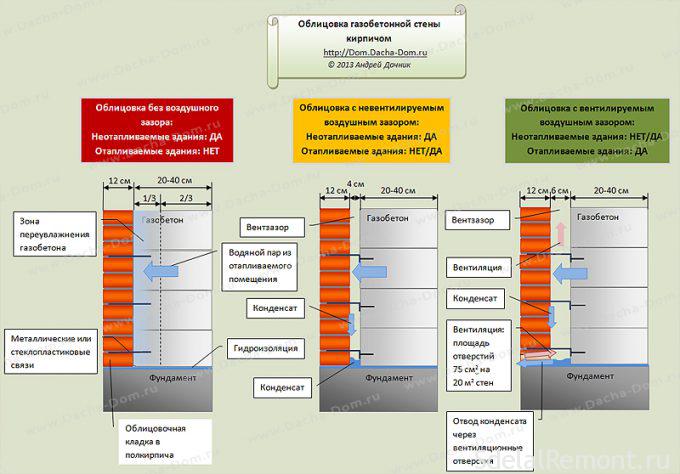

Methods of finishing the house

Aerated require mandatory finishes, because over time it can begin to absorb moisture. Additional lining helps retain heat, to give an attractive appearance structure.

Building can be oblitsevat, using facing brick, wall mounting is possible in different ways: This material not only has an attractive appearance, but also reliably protects against damage aerated, cold and moisture.

Between the lining and the wall can be placed insulation. Another brick advantage is the ability to breathe: it will take moisture away from aerated concrete, provide adequate ventilation facade. However, if the mortgage is not made initially, can be a problem, since there is no fixing of bricks with a supporting wall. This problem can be solved, It offers several ways to accomplish the task.

How is lined with gas concretes?

Fixing of bricks for bearing walls is one of the most important moments, but before you start it, you must deal with the whole technology. An important point is the width of the foundation, if you plan to brick finish, it should be of sufficient width for these works. Usually there is no problem.

Fixing of bricks to the wall may occur at different distances, all depends on, planned installation of insulation or not. If the insulation is, between concrete blocks and brick should leave a gap of at least 3 and no more 5 cm. Insulation should choose water-resistant, eg, well suited foam or similar materials. The walls need to leave the vents. brick or a ceramic is used for finishing M-150, or finishing, layer is laid in a brick, method of mounting a similar stacking wall.

Fixing of bricks to a heater can be close. If the heater is not planned, the bricks should not be pressed to the aerated concrete, Otherwise both materials will break down quickly, because they have different performance, and between the air layer must be.

Methods of attachment of bricks

Quite often, use screws for fastening of bricks, as it is the easiest and most inexpensive way to fixing materials. Buy the long wood screws that are on the market. Plus this method in the speed and reliability of connection.

If the wall has a sufficiently large area, the use of additional fasteners necessary, otherwise the foundation can lead or deforms the wall itself.

Using a ligation series or grid bars through 3-5 series necessarily, in any case,!

whether the gain is required openings?

Quite brittle material is aerated; mounting of bricks in the case with openings should occur in a special way, because it needed to be strengthened. If you do not do this, tiling with Suspension tresnet, To prevent this, in the construction of the joints between the facing bricks lay a small metal rod, whose diameter is 5 mm. The distance may be different, whichever, any width applied masonry. The connecting member due to the spot welding and the use of a profiled rod with the same cross-section. Important, so that after installation the rod seal was clamped tightly.

Fixing of bricks to the wall can be made with metal parts, which are attached to the anchors or screws, intended for aerated concrete. In order to make it possible to lay element, foam blocks attached to the special console. After such frame above windows and doorways arranged stirrups, allowing to create the framework necessary rigidity. This is the most modern way, previously applied a wide concrete beam, which was placed over the opening.

Fixing with pins

Quite often, mounting of bricks with gas concretes takes place by means of pins from armatures. Establish their every need 5 rows of masonry.

You can often do gain, but not recommended for less, Pins must be separated by a 1 meter. Besides, between blocks stacked metal rods, which should act on 10 cm from the blocks.

Fixing of bricks in aerated by means of reinforcing pins must begin with the first row of bricks. Drill a small hole is made, after scoring a ribbed rebar.

To design the best kept, We make a small slope gorezontalny. Thereafter, the following series of overlapping and thus provide a reliable reinforcement of the banding. this affordable, but it requires great physical effort method.

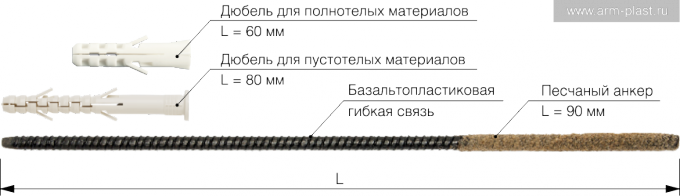

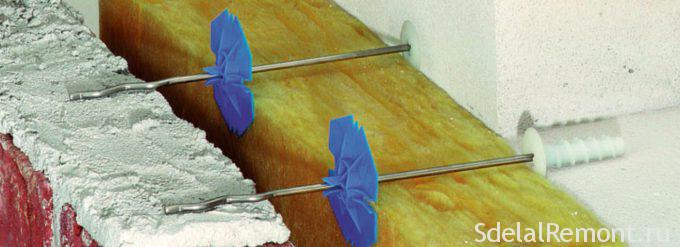

The use of flexible connections

Another reliable method of attaching the facing brick to the wall of aerated concrete - the use of flexible connections. There are different options and manufacturers. There are several types of these materials: fiberglass, bazaltoplastykovыe. True cost of their ranges from 10 to 60 rub. for pike, and it does not always have the opportunity to purchase.

Durability of flexible connections - this is one of the key features, which look like when selecting consumables. Masters-known fact, that the outdoor portion of the wall under the influence of moisture and temperature fluctuations can change the size and deformed, "Walking" with respect to a fixed bearing masonry. Strong balzatovye fibers allow the outer wall to resize and move, without creating the very wall stress.

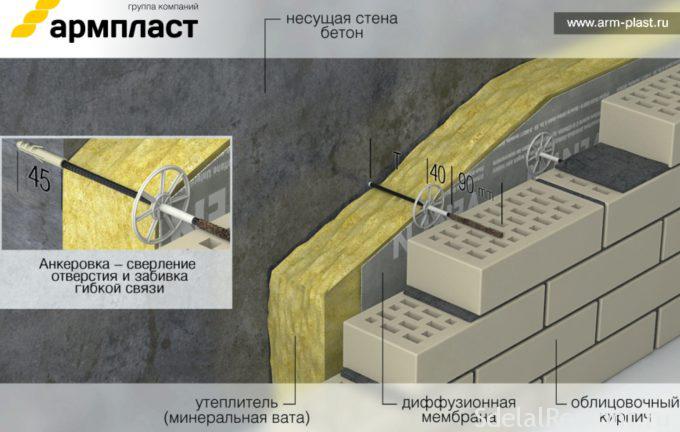

Communication from Armplast

The flexible link is a rod made of basalt sand coated with. Sand coated anchors are used when connecting the concrete wall panels. Sand anchors provide adhesion of mortar, as well as protection against corrosion in the alkaline environment of the concrete.

Using balzatovyh rods for masonry significantly increases the operating life of the structure.

- Basalt flexible communication from the company "Armplast" has a number of advantages:

- The low level of thermal conductivity;

- High flexibility and strength;

- Not susceptible to corrosion or any other negative effects in the alkaline cement environment;

- Are not subject to deformation.

Company Website https://arm-plast.ru

Variants of the company Glen

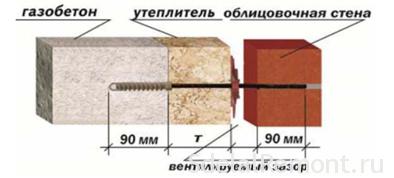

If you wish to carry out work on the facade facing clinker brick after, there is no need to lay a flexible connection in the process of construction of load-bearing wall, and use special flexible connections for use with a ready base.

This flexible connection basalt GALEN 6-aerated concrete intended for installation in the base plate of a material with high porosity: concrete blocks or concrete blocks

Material: bazaltoplastyk

- diameter - 6 mm;

- Minimum anchorage depth - 90 mm;

- Tensile modulus of elasticity - 51000 MPa;

- Modulus of elasticity in compression - 30000 MPa;

- Ultimate tensile stress, not less than - 1000 MPa;

- Breaking bending stress - minimum 1000 MPa;

- Meaning efforts on digging, at least H

for aerated concrete D400 - at least 2500 n;

for aerated concrete D500 - at least 3000 n;

for aerated concrete D600 - at least 4000 n. - The strain at break - at least 3 %;

- Coefficient of thermal conductivity - 0,46 W / m * 0C.

- Consumption: depending on the distance between the walls (5-9 Pieces / m2). **Table calculation flexible communication flow, see below.

- insulation clamps for fixing an optional insulation

- length options: 180 – 400 mm.

Flexible connection ZV-Welle

Flexible connection ZV-Welle made of stainless steel, designed to bind the front facing brickwork and bearing walls, made of a dense construction material, such as, eg, concrete or solid brick building brick, and issuing the ventilation gap between them.

Flexible connection Bever ZV-Welle used then, when the supporting structure of the dense material is already built and there is no possibility to use less costly flexible connection for installation in masonry bearing joints.

Applying this relationship to a flexible porous base (aerated, penoblok) only with low height buildings (to 4 m), in other cases, for porous substrates, use flexible connection Bever PB 10 with increased capsule.

Flexible connection Bever ZV Welle supplied has spacers binding element in stainless steel and nylon dowel.

It is set as follows:: a first bearing wall drilled hole 8 mm and a depth 60 mm. Then hammered dowels. Then, within a dowel with a special casing oscillator element (It is in each package) and a hammer, a dowel mounted expansible flexible coupling element.

In this way, in a double masonry systems (an inner layer - carrying a dense monolithic concrete or solid building bricks and an outer layer of bricks) flexible connection Bever ZV-Welle uses sequential erection of walls double brick (first elevated support base, then facing brickwork).

- Material: stainless steel (link) and polyamide (dowel).

- The depth of penetration into the joint load-bearing wall: 50 mm.

- The depth of penetration into the seam facing brickwork: 50 mm.

- Consumption: depending on the width of the ventilation gap (5-9 Pieces / m2).

- clamps for fixing an optional insulation Iso Clip .

- length options: 160 – 320 mm.

Recommendations for use

By means of such links occurs attachment of bricks to the supporting wall, it takes to pick up the product properly, which must meet the following requirements:

- applicable products, if the house is ready, they can be inserted, Drill a hole in the wall at any time.

- One of the ends of the anchor should have a wavy profile, second - have the form, that will meet your needs, eg, for fastening plates.

- If the seams are tight, It needs to anchor with a curved end.

- Spiral used for driving the tip into the material.

- If you use a dowel, required anchor screw tip.

- Preference is given to rust-free materials, eg, galvanized .

- product diameter should not be more than 4-5 mm.

- In order to secure anchor, bearing wall is drilled, inserted into her plastic dowels, then assembled compound itself.

Fixing of bricks ties – the simplest and most affordable way. Positioning the anchor so you need, to the walls of a square meter had no more than five, possess necessary staggered: most convenient 50 cm horizontal and 40 cm vertically.

If you want to create the frame openings, make a step 30 cm, in this case the most solid attachment of bricks and aerated concrete, It is not reduced carrying capacity of the wall. If the distance is measured from the corner of the building, should not be less than the retreat from them 150 mm, Ideally indent should make 250.

The use of masonry grids

Fixing of bricks to the supporting wall is very often carried out by means of masonry grid. It's quite old, but reliable way. The grid is not expensive, It does not require complicated installation, but it must be laid at the time of construction of the wall of aerated concrete, to attach the finished design net will not work. The grid is needed in order, so that when the structure shrink the load is distributed evenly and does not cause cracks in the facade. Can be used metal product or of galvanized mesh.

Fixing of bricks to the wall with the grid must take place every three rows. If masonry is used from 2 blocks, you can put a grid every 4 a number. If not used very strong blocks, is allowed more frequent stacking mesh, but in no case more than a rare. Reinforce number must be at zero: it will firmly secure the trim, to avoid its damage in the future.

This type of fastening for facing bricks can be made of different materials, eg, become, fiberglass. choosing grid, it is necessary to pay attention to its rigidity, eg, fiberglass is not suitable for

wall sections, which affects a large load. It considered the safest metal mesh, it can be used for all types of buildings.

Steel good springy, not afraid of strong physical influences, strong tensile, thus it is lightweight and does not overload the structure. This is one of the most simple and practical fasteners for brick facing brick. Metal mesh acute, therefore a high risk of injury. Basalt in this regard is much safer, moreover, it does not rust, and the load can withstand the same.

Fixing walls of bricks by using aerated concrete grid has the following features:

- Holds up 50 kN / m.

- It has high strength.

- Light weight product does not affect the design as an additional burden.

- can stretch, therefore it has a certain plasticity.

- If you use a metal mesh, inside walls may form cold bridges, Basalt option eliminates this problem.

- It is worth noting, that tension is stronger precisely basaltic grid.

- Not afraid of the impact of the environment. If the mesh of stainless steel or basalt, ordinary steel under the influence of moisture and oxygen can oxidize, causing rust appears, and the product eventually loses its quality.

Conclusion: fixing to aerated concrete facing brick perhaps a variety of ways, the choice of which depends not only on the cost of the product, but also on the stage of construction.

How to lay tile, brick above the window

When facing clinker brick built house, often is the problem, how to get around the window and dock with the window because there zazok between the wall and masonry. Of course there are ready solutions zamudrennye fixing bricks around the window, But consider the cost and the number of windows it turns expensive.

Just solve the problem junction box and masonry turned using metal corner 120h120h9 mm and custom bent sheet metal. This method allowed the right to receive the finished result. Perhaps, it was the easiest solution for the device of the upper slope of the window frame at facing brick already built homes

If you have your ways to overlap the window aperture share in the comments. In this farewell, Good luck in building!