The use of multiple types of flooring in one area always entails the question "how to dock a tile and laminate". After all, it must be done not only visually beautiful, but also qualitatively. many are thinking today about, to divide the kitchen into two zones: and working place for lunch. Therefore, the portion of the floor, where the kitchen, spread tiles, and another part of the room - laminate.

Why combine coverage?

The combination of multiple coatings in a room provides a number of evident advantages, eg:

- Ability to create your own interior design and choose the desired color range of materials.

- Separation zones into several segments, depending on their destination. these cities, where ever there is a movement, can drop heavy objects, dirty floor - is recommended oblitsevat tiles, a second room floor area, where people will only spend some of the time, It can be finished with laminate.

- Ease of cleaning the floor covering, as well as increased service life.

- Such a move would help to visually enlarge the space of the room.

- Savings in costs flooring. You do not need to buy a tile for the whole kitchen area, if it has a large volume. Instead of this, financial costs decrease, if half of the room covered with laminate, which has a lower cost.

In addition to the kitchen, the division of space is also found in other rooms of the house, hallway or corridor e.g.. In these areas there is also a likelihood of contamination of constant sex. In these cases,, to the site will have floor tiles and porcelain tiles. The latter variant is distinguished by its high cost, and therefore oblitsevat them all over the floor in the room is too expensive. Therefore it is necessary to combine the tiles with laminate, and a smooth transition with the help of the nut to visually divide the room into zones.

The choice of joining method

At the moment, several methods tiles engages with laminate. Some of them require a long and painstaking work, others - easier to install and are common.

Tight fitting materials

This method is good for connecting the same type of finishing materials, Internal space in e.g.. Connect manner and plate laminate may, but this process will require perseverance and accuracy in work. For the reason that, floor tile that has a much greater thickness than laminate, We have to raise the level of ties in the zone, where there will be the last.

Achieve perfect smooth interface still does not work due to the difference of material properties. Under the influence of temperature the laminate can increase in size. For, In order to prevent such a situation, the seam between the tiles and laminate fill grouting, whereupon it is cleaned to a state with a floor covering coincide. Of course option is possible, if glued laminate board to the floor on liquid nails or silicone, and tile joint with lamiatom fluff acrylic sealant.

The main rule in floating floors made of laminate to thus fixed side there was only one, and the rest were free of linear expansion.

Junction with silicone

This method is based on the entry connection seam using silicone sealants and. The use of these materials will make the seam inconspicuous. The material to fill the seam is selected in the color material to a finishing.

If in the future you will have to make repairs, then remove the flooring will not be easy - it is a disadvantage of this method. Also it requires accuracy in work - in fact the foam or sealant should be applied slowly. The advantage of this method can be considered reliable and rugged construction.

The use of cork compensator

This method is an innovation in the field of construction. This method differs durability and reliability. The cork material has the ability to compress, and therefore will not deform the floor. Also, the compensator of cork sealed and aesthetically fill the seam and is an alternative to the most popular method of interface - Nut.

With toning compensator can achieve the desired color. However, this method requires a perfect fit material, otherwise it is impossible to use cork compensator.

The use of the nut for the joint

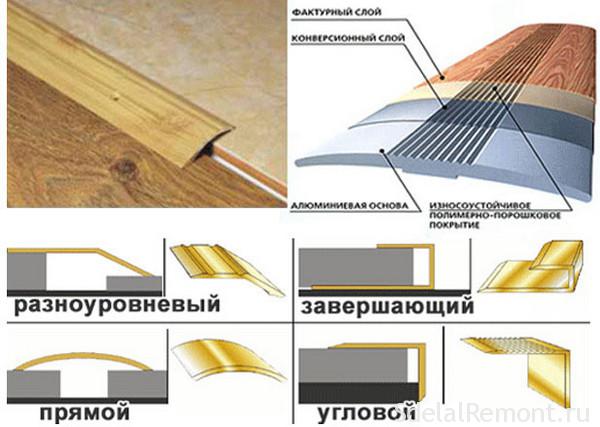

The most common, effective and affordable method for today. This method compares favorably with the other, that has a number of advantages. A variety of materials for the nut lets you choose the, which is most suitable in style: aluminum, wood, plastic or steel.

If the joint has a non-standard shape, such as bends, the plastic sills help to cope with this issue. Another plus the use of the nut - the ability to hide all the bumps and joint defects. So the deciding factor in choosing this method of docking between tiles and laminate - it is easy to install and variety of colors.

The choice is up to the consumer, so before the method defined docking coatings, Think about what option most suitable for your materials.

Features installation of the nut at the junction

Since the option of using thresholds at the joints between the tiles and the laminate is the most common, you need to know some of the nuances of installation.

Sills are made from different materials: tree - rarely used, since they have a tendency to fissuring; plastic - are often equipped with a special rubber gasket for a snug fit to the joint; Aluminum - the most popular version of the product because of its durability and strength.

Depending on the type of connection sills are:

- With a through fixing. Option is good, that is easy to install, and also is capable hide small height difference between coatings. In addition, a nut thrown on a sealed adhesive.

- The shape of the H-shaped strap. Such a construction comprises grooves on both sides. On one side of the bottom portion of the article is put laminate, and on the other - tiles. The gaps are filled with the respective material - silicone and grout.

- folding strip. Here, the nut is based on two T-shaped strips, both coatings are laid on the joint line. Further, they are connected in one piece, then set escutcheon, which snaps on top.

To install the metal nut, which has a through mounting, must:

- Measure the length of the joint and to measure this distance on the product.

- Attach the nut to the coupling place and identify points for fasteners.

- With perforator, drill or screwdriver, drill holes, diameter suitable to samorezah, which will be attached nut.

- The product insert seals and attach to the installation site using the fasteners.

With concealed fastening nut has a slightly different procedure for installation:

- Unpack the product and cut on both sides of the length, equal to the length of the doorway;

- With the tool to drill holes in the floor at the joint;

- The resulting holes install plastic dowels;

- The groove on the inside of the nut insert screws and place them, to match its location in the floor with dowels;

- Carefully insert the product into the holes;

- Fasten the nut to the floor with mallets neat movements. To prevent damage to the product, Use a wooden block.

Easy to install the nut to the joint between the laminate and tile determines its popularity among consumers. Proper installation will ensure the aesthetic appearance of the floor covering.