cold floor, especially in winter, - is the key to a quick colds, Climate uncomfortable atmosphere in the house. here, holding on warming of the grounds - an urgent need. One of the options, characterized by a simple and affordable, - floor insulation foam.

Reasons base insulation

The living area is not completely closed by heat. heat withdrawal occurs through windows, balcony, doors, walls, ceiling and floor. At last accounts to 10-15% of the total leakage. In the reality, in one-storey houses of the old buildings, It pulls up the base 30% heat.

Main tasks, pursued by the base protection:

- to prevent the penetration of cold in the house;

- eliminate heat loss, i.e, stop "street heat";

- offset dewpoint (of condensation), reducing the risk of mold, rot in the underground space;

- rational use of energy, allocated system "warm floor", - most of the heat goes to the heating of the room.

Solving such problems is achieved, if the warm floor foam.

types of foam

Foam - separate type polymers. It is a foamed plastic mass. It consists of individual beads-cells (pellets). Variety - Styrofoam. Widespread brand PSB-S (bespressovy polystyrene). According to the structure to 95-98% consists of gas.

The first type has a looser structure, easily damaged by mechanical action. But wins in the price. The second type, with comparable figures on the thermal conductivity, stronger, but more expensive.

The market represents one more type of insulation - penoplex. different density, strength. It has the best performance of thermal conductivity, group than foams. But its price is higher.

Choosing types of polystyrene used for insulation floor, We must take into account a number of factors:

- Installation method - Ground, under the concrete floor or it will foam insulation slabs. Here, the value play water absorption, mechanical strength and thermal conductivity.

- cost of production. traditional products (foam ball) It has the lowest price, but crumbles, damaged during installation. Warming of the floor Penoplex cost more, but the effect of thermal protection above. It explains the design feature. This product is on the edges of shoulder. I.e, styling made overlap, without formation of through-seam.

Ease of installation. determined:

- freedom of access to the object of insulation (narrow or wide room);

- its design (availability of external parts, eg, clay, beams, pipe);

- evenness of the surface, and other factors.

Based on this, are determined by the size of foam to insulate the floor. Determining parameter - the thickness of the article.

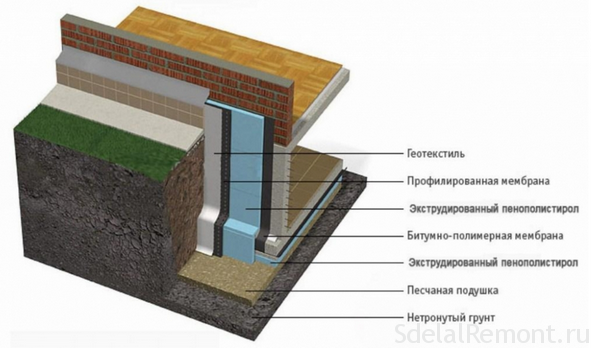

- Moisture sources. For private houses - is the level of groundwater and the presence of waterproofing. The presence of moisture, increases the thermal conductivity coefficient, reducing the effectiveness of measures for insulation.

- Location of heat sources, electrical wires. This aspect is important for fire safety. Polymers not support combustion, but open flame heating emit a pungent, preventing breathing, smoke.

Products PSB-S available in sheets with dimensions (the most common) 1000 x 2000 mm. The thickness of 25-500 mm. Penoplex 600 x 1200 (2400) x 20-100 mm (width, length, thickness).

that warm

Foam for thermal insulation of the floor is used in the following cases:

- insulation of ceiling multistory building; true for the first floor (presence in the basement boiler or open skylights);

- protection of premises from the base of the penetration of cold from the non-heated basement or cellar;

- insulation slab foundation, serving base for floor covering device;

- creating layer during laying "Warm floor";

- cut-off effect of the temperature of the background from the land during the construction frame houses or similar wooden structures.

installation

Laying a protective coating It is not a complicated process. Therefore, the operation of insulation foam floor with their hands quite capable of many people. Nuances are as preconditioning the base prior to assembly and prior alignment .

Laying a protective coating It is not a complicated process. Therefore, the operation of insulation foam floor with their hands quite capable of many people. Nuances are as preconditioning the base prior to assembly and prior alignment .

The most optimal solution - placing the bottom layer overlap. Thus it is cut off the cold flow. This is possible at the initial stage of construction or basement has the necessary parameters of high-rise.

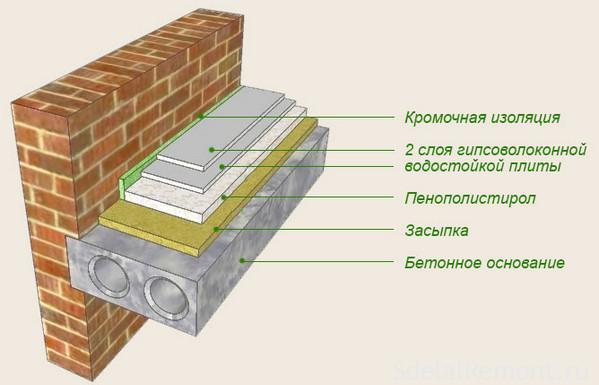

Isolation of soil require device gidromembrany. This can be used as conventional materials, - ruberoyd, Bikrost, thick greenhouse film, layered crosswise.

Council: material is capable of deformation. Consequently, size sheets and insulated space, may vary by 2-5 mm. Such a process is called "interference fit".

floor insulation foam technology in the room consists of a series of events:

- Autopsy wooden support (of necessity).

- removal of debris, impregnation of the concrete base acrylic primer.

- Apparatus waterproofing layer.

- Placing lag, mount. Supports advisable to place, taking into account respect for the strength, rigidity of the wooden floors and insulation sizes.

- Further, the foam is placed on the floor. Plates stacked without forming through-seams.

- Fits vapor barrier. Mounted floor finishing.

Council. Through-seams are eliminated with foam, - it holds the plate between itself and has insulating properties.

For private housing, insulation is placed in advance on the floor and poured a concrete screed.

so. If you want to protect from the cold floor, – insulation foam the optimum solution for private housing or apartment, located in a high-rise building. This will provide cost savings on an inexpensive material and the ability to perform the work with his own hands.