Method semi screed has as main component the use of mortar in dry state. Apart from the quality of cement in the mixture contained various additives, allowing its use in certain circumstances and weather conditions. Due to carry out the installation takes much less time to deck flooring, Quality and strength and durability are increased at times. A sufficient number of positive aspects of increasing the demand and interest of the artists work.

styling options

Before, how to learn, how to make a semi-dry screed, It should stay at the specific embodiments of the solution styling:

- Use of a polyethylene substrate. Here she is called the "floating" because, that it in no place is not in contact with the floor base (ceiling), as well as the walls.

- Denial of pads. Mounting works are performed directly with the base slab. No additional elements here do not need.

- Performing ties with the substrate for soundproofing. Sound-proof membrane are stacked immediately on flooded screed. If here to add polyethylene foam, the result will be more than perfect.

- Increased thermal insulating qualities by the use of appropriate substrate. This option is more suitable and optimal in private construction, when lying flat on the ground floors of buildings. In most cases, as the material here is a slab of mineral wool.

Each of these device embodiments semi-dry screeds the room is different in the final result. One can even sochlenyat them together and thereby increasing the specific characteristics of the floor. But in most cases, pay attention on the building itself or the room, wherein the work is carried out.

The main pros and cons

Looking at reviews on the Internet, semi-dry floor screed with their hands is very fast and does not require specific knowledge in construction. But then do not need to run headlong into the store and purchase the dry mortar. It is important to understand that, what are the semi-pros ties for sex, and what difficulties may be encountered. If we talk about the disadvantages, more often, when a semi-dry screed with their hands, Technology is not respected. Any violations that would lead to negative consequences.

Among the positive aspects distinguish the most basic of them, allowing not to think about, some screed floor is better to make in an apartment, and stop it on a semi-dry version:

- In most cases, such a variant device screed It will cost a little bit cheaper, than "wet" version.

- Increased thermal and sound insulation properties of the premises, where construction works are carried out. This is achieved by the porous structure of the embodiment in the final solution.

- Sex becomes perfectly smooth under any floor covering. You do not need to make any other arrangements for the equalization. This reduces the period of works, and also saves power and money.

- After drying the cast solution cracking and rainfall places negated. This is most characteristic of "wet" floor device.

- The final solution does not flow on the lower floors and you can not worry about, that they will be filled. The cause of all this - a low amount of water used.

But this is only the main points, that attract customers. Especially thinking about, how to make a semi-dry screed with their hands, owners of apartments in new buildings.  They try to carry out all the work as quickly as possible, to settle and to celebrate the housewarming. But we must not forget about those cons, that may be encountered when using a semi-dry screeds in the creation of a "rough" sex options. Most often this is due to not compliance solution creation proportions, namely a large amount of water to be added. If you fulfill all the points and the requirements of the manufacturer of construction dry mix, the problem will not occur. When the semi-dry floor screed in the apartment manually, practically no other deficiencies.

They try to carry out all the work as quickly as possible, to settle and to celebrate the housewarming. But we must not forget about those cons, that may be encountered when using a semi-dry screeds in the creation of a "rough" sex options. Most often this is due to not compliance solution creation proportions, namely a large amount of water to be added. If you fulfill all the points and the requirements of the manufacturer of construction dry mix, the problem will not occur. When the semi-dry floor screed in the apartment manually, practically no other deficiencies.

But here mechanized option It makes its own adjustments. The first and basic of all it is about the use of expensive specialized equipment. Its expensive, even to rent, not to mention the purchase of a unit of work. By the time it will be much faster, but you have to pay a decent amount of money. It should be ready for the cost.

Materials and tools

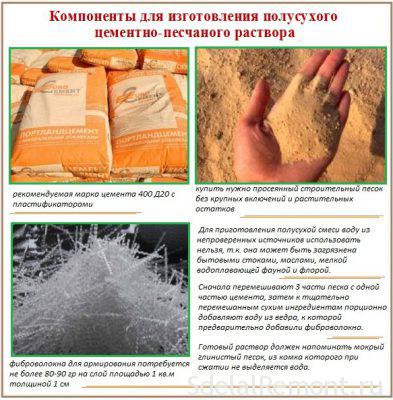

If you already know about, how to make a semi-dry floor screed, should think about buying the necessary materials and tools for the job. It is the quality of materials will affect the service life of the finished screed, as well as to the manifestation of its positive properties and characteristics. The main components here sand and cement. It is best to focus on a proven seller and manufacturer specific. There are many cases of consumer fraud, when it sold under the guise of a completely different quality raw materials, markedly different in quality. generally need:

We should not forget about the tools. The solution is easy to prepare using a mixer. Solution suitable for leveling generally defined length. All performed in a healthy way - to buy gloves and goggles. Aftercare of the screed is performed using EPS float or metal trowel, metal comb, resembling a conventional rake for leaves. On top of the cast solution stacked film of polyethylene, which is necessary for uniform moisture distribution throughout the bed. Also the number of tools included level (Laser is more accurate).

some deem, that perform screed without reinforcement in no case be. There could not agree more. But instead of the usual steel mesh in the modern world of semi-dry screed in the apartment is carried out with the addition of fiberglass.

Work to do better 2-3 people at the same time. One solution would be to mix, distributes it to the second floor space, and the third is already beginning to tamp and sanded surface for floor covering.

preliminaries

Before the start of the folding solution on the area in the room room, it is very important to prepare the base. This will give an answer to the, how to make a semi-dry screed floor with their hands correctly and accurately. Killed all the available waste, and mud. In this case, useful building cleaner, which is able to even collect all the dust. It would in any case unnecessary during execution of works. Any slight deformation of the surface are stripped using sandpaper. More noticeable - are sealed or removed. It applies grout, unshrinkable.

Important waterproofing layer. As a material suitable film of polyethylene, having a minimum thickness 200 micron. There are also specialized materials, eg "Izolon". He is protective against moisture, and also increases the properties of sound and heat insulation in the room. The choice will be only for the performer. In any case, they will perform all of the required quality for the future of "rough" sex.

Optimal variant laying a waterproofing layer - a continuous web. But not always, it will be enough for the whole area in the room. In this case, you can make starts one element to another with a distance of 15-20 cm. They should not be adjacent to each other, and go. Also, it is important to start the film and the walls to a height, several large, what future screed. Subsequently, it can be cut without problems.

Many people know about, how to make polusuhaya screed, but forget about the walls in the room. They should also be prepared to work. Walls and any architectural structure should be isolated. In this case a damper tape. It is adhered around the perimeter. The upper limit of the tape should protrude above the tie. A damping solution feed contributes standoff cracked, after drying, and it will not be afraid of any compression and uncompressing the action of external and internal factors. At the end of the work, all the tabs can easily be cut using a knife stationery.

The usual way to install beacons

When using a laser or conventional level determines the zero boundary floor. On it are established beacons to a semi-dry floor screed.

beacons supports can be made of cement mortar or gypsum mixture. The guide beacons are exposed from the metal profile, strips of wood, tendons etc..All beacons installed on a level equal to. The greater the number, the more accurate the final results, the floor surface will be smoother. It is important to take into account the length of the rule used. The distance between the beacons should be less than a given length of approximately 10-15 cm.

When the flashing profiles are taken, they are attached to the base parallel to one of the selected wall in the room. The first of these is set around 200 mm from the wall. Further, they are evenly distributed and optimally throughout the area.

Mixtures for beacons of grout can be purchased off the shelf at any hardware store. But if the answer is given, how to make a semi-dry screed on their own, then the solution can be prepared by yourself. The main thing to observe precisely the proportions and that the solution itself turned out not rare.

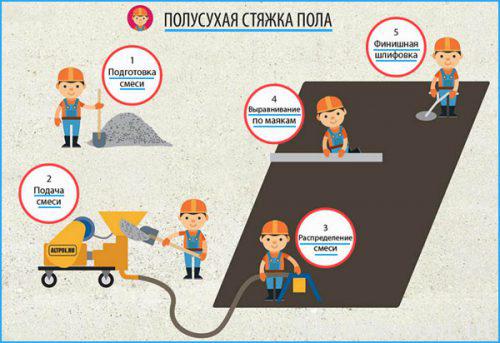

Mixing the solution

When mixing the solution should follow a very simple rule - cook it on the exposed proportions without deviation.  Cement and sand is taken in the ratio 1 to 3, and for each cubic meter of final solution is taken 600 gram of fiberglass as a reinforcing element. For every 100 taken kg of cement to be added 1 liter plasticizer.

Cement and sand is taken in the ratio 1 to 3, and for each cubic meter of final solution is taken 600 gram of fiberglass as a reinforcing element. For every 100 taken kg of cement to be added 1 liter plasticizer.

As the capacity for solution will suit perfect any utensils, barrel. The alternative - a special mixer. Should adhere to the sequence of work:

- River sand in a quantity 130 gallons poured into the container used.

- added fibrovolokno and plasticizer 140 g i 0.5 liter, respectively.

- fill 50 kg of cement.

- All components are mixed thoroughly, then add about 15 liters of water.

The container may be of any size, but the proportions must be observed at all times. The most important thing, the solution turned to a liquid. Quality Checks follows: should be compressed a small amount in the fist, and if there is no moisture isolation, then you can start installation. At the same time it must not crumble.

Stacking ready mix

Lighthouses are exposed, solution, reinforced fiberglass, implicated, you can start working. Semi-dry screed independently starts from the opposite wall from the entrance. Filled the distance between the two mounted beacons and with normally contracted by the right and left to itself.

You can not be afraid to close several exposed lighthouses, as often as they remain forever in the solution. Sometimes it gets profiles, and the voids are filled with a mixture of finished, after which it must tamp. The thickness of the screed when it is usually done minimally 40 mm. Much will depend directly on the evenness of the base.

Once strainer It laid out all over the place, it should be compacted. The best option - if this process will execute the other person during the filling solution. This will reduce the number of times, but do not have to be distracted by another job.

Zatirka

When all of the solution after the mounting carefully tamped, you can proceed to the final work - grout. If you do not want to spend the extra money and involve special equipment surcharge, you can take a trowel strip of a certain width. Since it performs a rubbing the entire surface in a circular motion. As a more worthwhile alternative - equipment for grinding disc type. Work with it will be carried out more efficiently and in the shortest possible time. Besides further carried ramming and.

Do not be amiss to bring to work and another person, especially if a large area of the premises, where the installation is carried out. There are time limits, which should meet in grinding surface. It begins not earlier, than 20 minutes after placing solution, but should not be allowed more than six hours of downtime.

cost of

Everyone wants to know, how much it costs to make a semi-dry floor screed. Furthermore purchases all the necessary tools for, and the material, worth here to add the cost of delivery to the place of installation, raise to a specific floor, laborers pay production, rent special equipment (it shall be sufficient and grinding apparatus). Specific cost should determine the choice of the store, as well as company, providing such services.

But this option is the best tie due to a great final result. The most important thing to comply with mounting technology "rough" sex, and any nuances there is not exactly.