For any premises very important level floor. From it will depend not only on the quality of the flooring floor covering, but also the location of all the furniture. In addition, carry out any additional leveling measures do not have to (grinding, polish). Accustomed to all variants of the floor device does not always produce the desired result immediately. In this case, the aid will come mechanized polusuhaya screed, having a sufficient number of positive qualities. He was noticeably different from the "wet" ties by reducing the number of persons involved and the time spent.

The need machinemade

Mechanized semi-dry floor screeds come in handy in the event, when the final coating "rough" sex is necessary to make a really final. It can also be used for the subsequent decorative finish. With this embodiment, the floor is not only smooth over the entire plane, but also very durable.

For such floorings, as laminate or, eg parquet, very important mechanical floor screed, since it requires fairly smooth surface. Special effort here will not be, and the result will please everyone. Such embodiment will have to use a semi-dry screed for additional acoustic insulation layer. Sex becomes rigid and sturdy, It allows you to hide the available communication indoors, wiring the electric wires or tubes. irreplaceable floor screed mechanized means under Heated floor, what kind he was not.

As components of such a semi-dry screed execution protrude sand-cement components. They have a variety of additives, responsible for those or other qualities of a future solution. Here is isolated modern material fibrovolokno, and granotsev. As a basis for such semi-dry suit tie concrete floor slab, and rammed gravel. Special project for the tie involves the use of litter layer.

Its main difference from the classical variant screed - minimal use of water. enough, to cement filled. You can not overdo it here. In this manifests less shrinkage final solution after installation, cracking minimized. The technology must be observed at all stages of work on the device of a semi-dry screeds.

Advantage machinemade

The technology of semi-mechanized way tie has its own characteristics, that exhibit some positive traits. Of course, You can not ignore the disadvantages. true, past often arise due to the fact, that the whole process is carried out not in full, not adhering to the advice of experts. The advantages include:

- rapid erection. Following the laying of semi-dry screed in such a way, the water evaporates very quickly due to its small number of. even later 1-2 hours using special equipment, You can move over the surface of the screed drenched. It's necessary, to carry out grouting. The whole process just prior to laying the flooring takes a very short time.

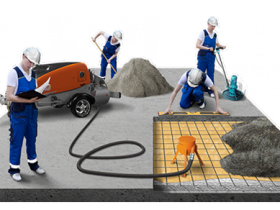

- In the semi-dry process apparatus screed special equipment into operation, which include high-performance cars. Downtime is not happening. Work crews at one time able to produce fill the order 200-250 square meters of screed. I.e, Preparation of the base under the tile or laminate is carried out on the whole apartment for one day. Manual coupler has disadvantages in such a case in time expenditure - batch solution, its transportation, subsequent installation, retracting lighthouses and more.

- No cracks after shrinkage. Screed hardens better, and its quality is increasing due to the small amount of water. Shrinkage cracks are most typical for the "wet" version. As a fight with cracks and apply a special material - fibrovolokno. The polypropylene fibers are added in the form of a dry mix and subsequently preparing the solution. They "run up" on all components of the mixture, creating a single entity.

- No additional planarizing. Due to the rotary power trowel, screed in the wet state passes grinding procedure. The result is a perfectly smooth surface, which can be safely used under any floor covering. On the square every three meters in height is acceptable discrepancy on 2 mm.

- All work on the preparation of the solution are carried out on the street. In the room at the same time there will be no dirt and debris.

- Lack of final solution to flow downstream floors.

- The automated process of laying.

disadvantages

We can not forget about the possible disadvantages of using a semi-dry screed machine. And most importantly there is Truce, that the need to use expensive equipment. So for a single performance of the installation will be greatly beneficial to the way. It is more important for construction companies. Even the hired equipment will require a decent financial expenses.

It is very important to handle the equipment. If no skill is not, then the result is unlikely to be positive. It is not always the firm will be able to take on the machine floor screed in a small room in 30-50 square meters. Most often they are the minimum order must be 100-150 m2.  So perform this variant semi-ties in a single room (room, kitchen), will not work. In this case, can only find a companion for himself. It may be neighbors in the building. Several apartments easily keep within such area.

So perform this variant semi-ties in a single room (room, kitchen), will not work. In this case, can only find a companion for himself. It may be neighbors in the building. Several apartments easily keep within such area.

The cost of performing the work will be higher due to the operation of expensive equipment. Manual version here much cheaper.

Technology

Fill screed mechanized way to perform specific construction firms. They possess a sufficient amount of art. At the initial stage of preparing the foundation for: removed all the existing garbage, dust, everything, that may prevent. Do not be amiss to process it soil solution. In the following layer is arranged, and waterproofing noise-. This is done by laying the polyethylene substrate. Its thickness will be sufficient to 5-10 mm.

Along the walls of the damper attached tape. the main thing, that each element was a big, layer than the future "rough" floor. After mounting and pour solution, extra weight elements are easily removed.

Exhibiting level is carried out on the entire perimeter. To facilitate the work of applied laser level. Zero level should take place at the highest point of the floor. According to it has carried out measurement of the required layer of the future "rough" sex.

The following mixture is prepare itself for operation. This is all performed in the hopper Pneumosupercharger. Minimum temperature should not be below -5 degrees. When it is not enough, it's frosty outside, it is possible to build a thermal room. To do this, there are many ways. And must adhere to the sequence of supply of necessary materials into the hopper:

- Sand;

- Fiberglass;

- Cement;

- Water together with plasticizers.

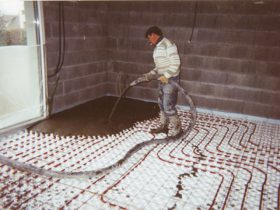

To shuffle will be enough and three minutes. Pneumosupercharger used in the subsequent delivery of the finished solution to, which will be carried out after all installation work.  As the main constituent of the equipment compressed air acts. Receiving solution is carried out in absorber. It is enough to attach to a hose conveying.

As the main constituent of the equipment compressed air acts. Receiving solution is carried out in absorber. It is enough to attach to a hose conveying.

Using the working mixture, Lighthouses are built around the perimeter of the room. Mechanical semi-dry screed must be performed at a room temperature of at least +5 degrees. Between beacons should be such a distance, which will be equal to the existing rule. Based on this, is determined and the required number of beacons. Pouring from a hose ready solution semi-dry screeds, it should be evenly distributed over the entire surface in the room.

Care after the works

A few hours after the above actions, there is grinding and smoothing screeds.  In this case, use the disk sander. any irregularities, fovea, bugorki, easily be remedied. That will have a really smooth surface, which can be laid completely any floor covering.

In this case, use the disk sander. any irregularities, fovea, bugorki, easily be remedied. That will have a really smooth surface, which can be laid completely any floor covering.

Even after about three hours, made expansion joints. Here come to the aid fugel. The depth of the joints should be within 10-18 mm, and their thickness - 4-6 mm. If there is no space project, they are executed in the doorway, which is adjacent to the colony, if there is a height difference.

When the room temperature and all other parameters have permanence, that little or no action to take will not have to. But if there are drafts, the sun is shining or low humidity in the room, the surface is covered with a film of polyethylene. For everything out of order 1-2 day.

Specialists generally recommended to wait for the deadline for drying semi-tie solution. It takes almost 4 weeks after installation. When the timing will not chase, better to wait, and only then proceed to the present flooring.

cost of

Machine semi-dry floor screed has its price. It will depend on, including most of the screed (gypsum concrete, peskobeton, mosaic, Heated floor under et al.). Nor rates affects the layer thickness, Fill the area. It also includes the use of specialized equipment.