With the construction of their own home everyone wants to get home, which would be the most cozy and comfortable atmosphere. To get a house, you must attach a significant funding.

But no matter, what will be the construction of, costs can be significantly reduced. And for that, there is absolutely no need to buy the cheapest materials and save on professional workers. So how can we get the savings without compromising the quality and comfort?

First of all, you need to choose the right building material. The modern market is literally littered with such products. But despite the wide range of, attention is paid to such a practical option, like glulam. Using a holistic approach, and knowing all the details of the construction with the use of this material, such a choice will significantly reduce costs.

Designing of country houses

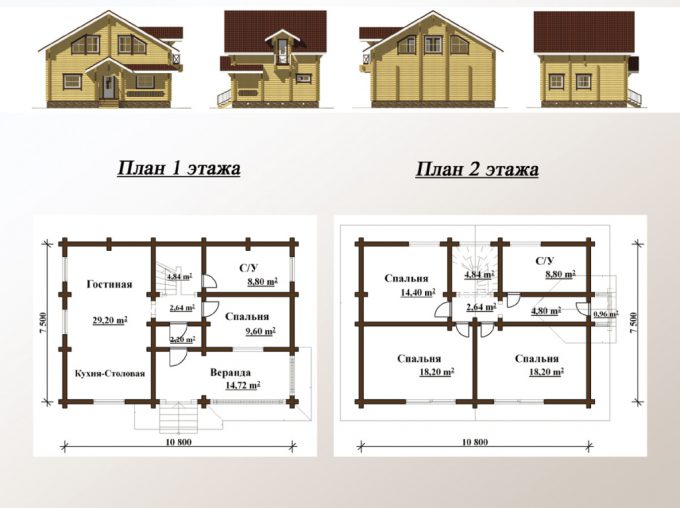

Proper design plays an equally important role in the optimization of budget. It greatly simplifies the construction of, and without compromising on quality, comfort and other characteristics of the house. For example, square shaped building will be cheaper, than a similar area, but elongated structure.

The spacious rooms and the formation of one large space from several smaller cheaper, than the large number of small rooms. It should be taken into account here as a parameter, as whether: if the family is big, the number of bedrooms will be appropriate, but if there are two or three people, the many facilities do not need.

As experts recommend, the design of the house of laminated veneer lumber is desirable to combine in one space living, dining room and lounge. It is a modern and highly effective method, allowing to save money and get a spacious room. On houses various embodiments of laminated board detail.

The advantages of laminated veneer lumber

Houses, constructed using this material, do not require a massive foundation. And this is a savings in construction equipment, time and materials. Natural wood texture, Use for the manufacture of laminated board, It eliminates the need to hold the inner and outer finishing. Since natural wood is a poor conductor of heat, You do not need to spend money on house warming of laminated veneer lumber. You can also save on additional heaters.

Carry out engineering work in the lumber house is possible immediately after the construction of the box, which is not the brick structures or buildings made of logs, which require a certain amount of time to shrink.

Another important factor is also the rapid construction of homes using laminated veneer lumber. This advantage allows you to save a lot of time, and the time, as known, money too.

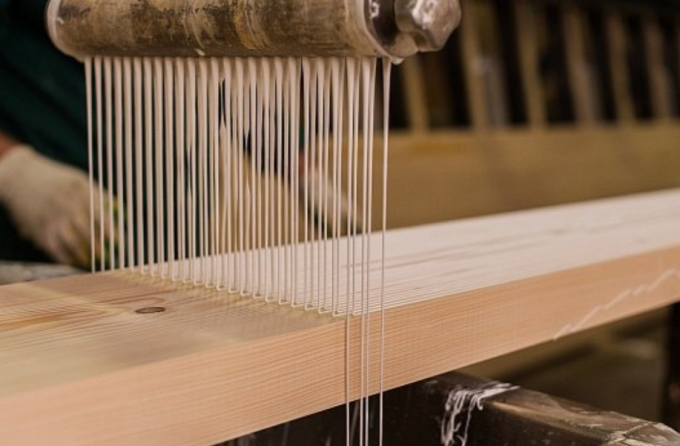

timber manufacturing process involves several steps. The most popular material for these products is wood spruce and pine, less frequently used cedar and larch. At the beginning of the logs made planks of the desired size and subjected to thorough drying, which takes a lot of time compared with the process of timber drying in solid. If boards have any damage, flaws, they are removed and produce antimicrobial preservatives and processing special impregnation to reduce the combustibility (flame retardants). Production timber occurs in special presses by gluing boards such well-sorted (they are called lamellae).

To beam turned moderately thick, need of 2 to 5 slat. The optimum size of the width 25 cm. For the bonding process, corresponding to international standard, use special waterproof adhesives, which not only give strength Brus, but also allow the wood to "breathe". In the manufacture of wood fiber direction of the timber relative to age the rings in the lamellae located in opposite sides, so glued structures more durable in comparison with whole array. it also features enhanced soundproofing, and the amplification humidity glued material is not deformed.

Laminated wood used in the construction of wooden houses in almost all of his designs: roof slabs, rafters, wall beam, shaped curved beams for houses with rounded shapes. Compared with whole array laminated material has a wide range of advantages. Consider the main ones:

- timber blanks are matched in texture and color, all visible defects are removed before gluing process, however very high surface quality with a presentable appearance;

- material laminated wood has a greater strength with respect to the integral bar (on 50-70%);

- over time, the shape of this design does not change, it is not deformed by any external influences, does not shrink, because in such a timber is no internal stress and its components before gluing process are thoroughly dry $

- wooden house, made of laminated veneer lumber has a high quality thermal characteristics. Therefore, the cost of an expensive heating equipment, its operation and transportation fuels greatly reduced. During the construction of such structures are so tightly joined to each other, that eliminates the need for insulation between them. Raindrops or snow are not available for these boards, and it reliably protects the building from the occurrence of the processes of decay and other lesions.

- If glulam is made of all the technological rules, its surface is smooth, smooth, without roughness, so the wall of the building looks indivisible. House from such material does not need exterior finishing;

- erection of structures in solid takes much more time, than the erection of laminated veneer lumber, since it is made using the latest technologies in the factory at a certain temperature and the set humidity norms. Installation design the finished basement is fast enough and does not require any additional costs. Shrinkage of the house of such material does not exceed 1%. (for comparison: building shrinkage of the planed or profiled timber exceeds 7%). With such a minimal degree of quality possible not only the construction of these structures all year round, but also the installation of the doors in the house, windows of various parameters, timely finishing works;

- the admissibility of wiring engineering and municipal communications hidden method;

- for the walls of the house does not require additional finishing, because lumber - almost ready-made material for the facade;

- other finishing materials "friends" with glued structures. They are well treated with wax, varnish, paint, and with proper care with optimum service life.

In our time, the public and individual building develops rapidly. Laminated wood is one of the most important places in the long list offered a choice of building materials, because different wide availability and low cost, and it makes this material very popular among different segments of the population.

engineering systems

On average, one third of the cost can be cut, if the house of laminated veneer lumber to build near the main communications. The advantage of this embodiment is, that can be easily and quickly connect to all necessary systems.

When choosing a heating system for the bar-shaped house you need to consider, that the acquisition of the gas equipment will be more expensive, than electrical. But the further operation of the first will be much cheaper. Construction of natural wood also does not require large expenditures for heating.

Finishing and equipping

Decided to build a house using laminated veneer lumber, expenditure item called "finishing" can immediately exclude. This material has remarkable excellent aesthetic properties, so finish it there is absolutely no need to. Due to the special manufacturing technology is a material, which has a flat and smooth surface, does not require alignment.

If the house of laminated veneer lumber want to change something in terms of design, the savings here would be palpable. For example, to give the walls a shade, only need to choose the right paint or tint impregnating composition. The use of such materials would cost very inexpensive.

If desired, radically transform the house in terms of colors, you can use drywall. This is an inexpensive, versatile and environmentally friendly material, whose installation does not require the use of building mixtures.

At the end should be added, that in order to obtain an optimal balance of quality and economy of the construction of bar-shaped house is desirable to entrust a reliable company, specializing in the construction of this kind of buildings. Organizations of this type today, there are quite a lot of, and each of them provides a full range of services - from design and choice of design to the cleaning of premises and garbage removal.

In the construction industry, the use of laminated veneer lumber is much more active. This material is well established in the construction of hangars, water parks, sporting, warehouses, shopping malls, that is, structures with large spans. It is widely used in individual housing.

https://www.youtube.com/watch?time_continue=1&v = g90C9V-gae8

https://www.youtube.com/watch?time_continue=167&v = EeuCmpaMciM