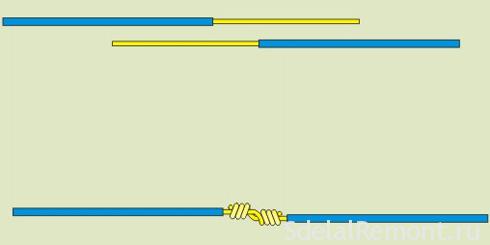

More recently has been the main way twisted wire connections in the home electrical wiring, and often in industrial premises. In modern electrical codes, this method is not even mentioned, although in practice, he now finds application. detail, about all the possible options for the connection of stranded wires.

Twisting and soldering two wires

Very reliable contact ensures soldering, to prepare a preliminary twist entirely appropriate and even necessary for a greater contact area (Considering, that the electrical conductivity of the solder below, than the soldered materials) and mechanical strength.

Brazing requires soldering capacity of 60-100 watts. You must first remove the insulation of the wires (4-5 cm), clean them with fine sandpaper and tinned with, ie. covered with a thin layer of solder.

- For copper wire can be used conventional rosin (a solid or as a solution) or special paste or liquid flux. Rosin and neutral bezotmyvochnye fluxes do not require subsequent removal, tk. do not cause corrosion.

- Acid soldering fluxes and other active use is undesirable - their residues can cause corrosion of wires and a short circuit even.

- There soldering materials and aluminum, but their use is not recommended.

Tinned wires twisted, then carefully propaivayutsya. Pike should cool down naturally, without forced cooling, which can lead to cracks in the compound. MREs convenient to isolate the heat-shrinkable tube of appropriate size, which, when heated, tightly encloses the junction. This is the most reliable way to connect electrical wires and cables as a copper, and aluminum.

Another option - a common masking tape, preferably not less than 3 layers.

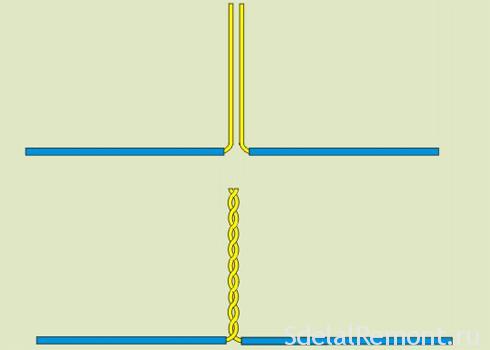

Insulating connecting clamps (YOU) It can be regarded as modern version of the old wires stranding. This is - a plastic housing, having an internally conical shape anodized spring. Bonding wires trimmed to a length of 10-15 mm, collected in a bun, and wind on their PPE - clockwise, against the stop. The total bond area, depending on the size - from 2,5 to 20 mm2. The connection quality is quite high, but somewhat less, than the screw terminals.

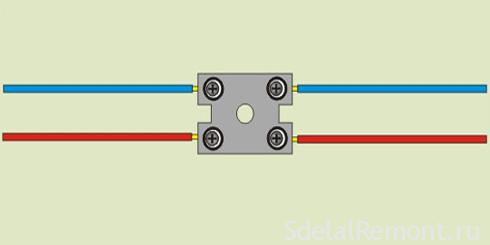

The compound of aluminum and copper wires with terminals

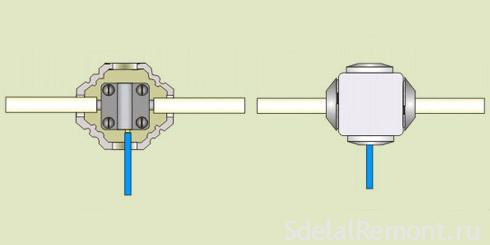

The most common screw terminals, They are often used in distribution boxes. Available in both small, and at very high currents. If you are using aluminum conductors, care must be taken when tightening the screws, because it is soft (and sometimes - and fragility) and easily damaged.

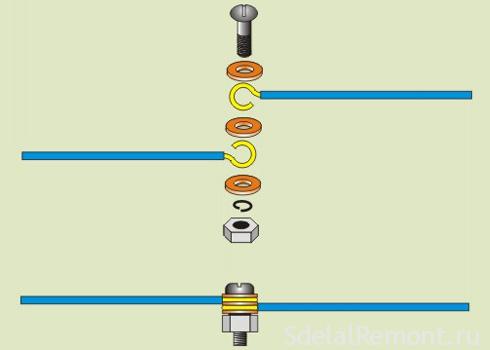

Compound cables screws with washers

This is a somewhat outdated version, in the absence of a suitable screw terminals suitable size, It provides a similar quality, It can be used to connect the aluminum wire with a copper.

Branch clip U-733

This is actually a variant of the screw terminal block, it allows you to take a branch from trunk, not cutting it.

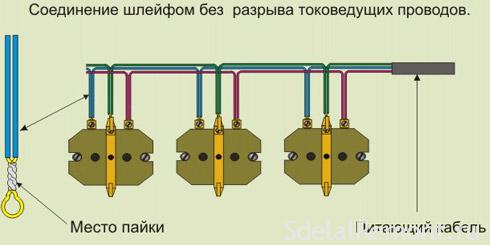

Compound several outlets loop

In this embodiment, socket can actually be used as screw terminals, but for greater reliability of the connection wires should be solder.

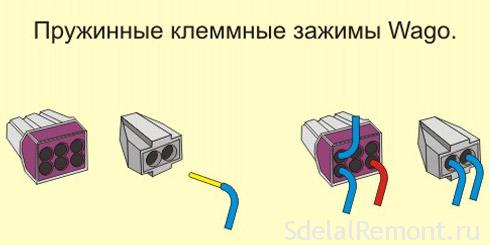

Self-clamping terminals Wago

Self-clamping terminals allow to connect electrical wires section to 2,5 square millimeters, allowable current can be up to 24 BUT. This is a very fast way to connect and technological. Stripping is carried out at a length of 10-12 mm, It does not require any twisting, no insulation, or even tightening the screws. The wires are simply inserted into the terminals,. Do not get so just connect flexible stranded wires.

Another drawback - in connection with a lower contact area, this compound is still somewhat less reliable, than screw terminal or, especially, soldering or welding.

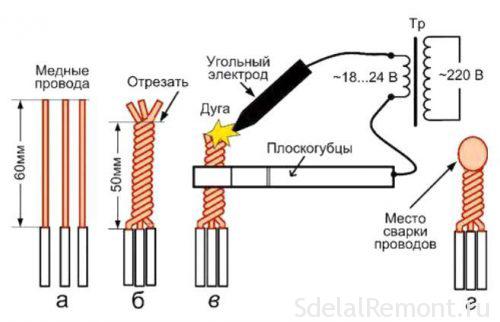

Connecting two cable conductors by welding

This is the most reliable way to connect, it provides the perfect touch and very long-term trouble-free operation. Electrical wires are twisted in the length of at least 50 mm, welding copper wires produced special carbon electrode coated with copper. It is best to use an inverter welding machine, although other options are possible. When welding wires, as with any other welding, must be strict compliance with safety regulations.

most importantly, remember, You can not directly connect and aluminum wires and copper, Only through the third metal. And about Wago, It has long been the clamps for soft wires

And for WAGO have pasta…