For cooking use electric, induction and gas panel. Each of them has its advantages and disadvantages, and there is a number of faults, which can be at the event of their occurrence correct yourself. Repair of the cooktop can be made with your own hands, subject to certain guidelines and with the necessary tools.

Repair electric cooktop

Repair hob Bosch, in some cases, can be done by yourself.

If the power supply is connected is not working one of the burners or the entire unit, the following work:

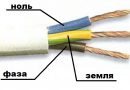

- Check with a multimeter AC mains voltage. If it is, so, the problem is most of the hob. Checking can use the indicator, but it only indicates the presence of voltage. A significant current change rates can result in triggering protective mechanisms.

- check the status of an electrical cord and plug. If there is mechanical damage will be sufficient to carry out the replacement of the cord or plug. It is also possible to check the current supplied to the panel itself, it is not always mechanical damage is the cause of the fault cord and plug.

- If the cord with plug, socket in good condition, conduct dismantling of the hob.

If to repair the glass ceramic hob with their hands worth knowing, that malfunction of some structural elements can be detected only with a multimeter, by carrying out measurements on individual sections of the chain. When considering the hob Bosh should pay attention to the elements outlined below:

- Termopredohranitely.

- Transformer.

When no resistance or at low rates should be carried out replacement of these elements.

Common problems of electric cooktops

Another common problem can be called a broken wire in the hob connection block. They may under certain circumstances otgoret or due to poor installation may be a bad contact. Check similar failure can be quite simple.

We select a few problems, which lead to malfunction of the cooking surface:

- Some models have fuses, that due to the strong power surge could burn out. Their cost is low, replacement procedure is quite simple. In order to protect expensive equipment from such situations should be installed to protect the device from power surges. With the constant failure of the fuse, check the features of the hardware itself, since the problem may not be in terms of the applied voltage.

- Burner may not work due to the fact, that lost contact at PETN. If transactions can be sealed-off back to resume work, why you need to have a soldering iron and know how to use. The problem may be associated with power supply, which are also often lost contact.

If the heating element has blown it must be replaced by new - If you do not work the sensor can solve the problem alone rarely. To begin with ping sensor, check whether the supplied voltage to it. Usually, sensor failure rarely occurs due to contact failure. Often to repair the touch panel is necessary in services, in some cases, can only be a complete replacement. An example of misuse of the hob may be mentioned the use of saline for washing, which leads to burn control unit.

- If the hotplate is not heated completely or overheats, which can lead to fire hazards, a high probability of failure of the thermostat. It is this structural element conducts control the temperature of the heated surface. Replace the thermostat can hold their own, why you need to conduct analysis of the hob. Depending on the model, the hob unit can be soldered to the chip, or connect via a special plug.

- The appearance of cracks or other defects not glass ceramic surface - rare, but all, also found. Often, the cause of such defects on the surface is allowed in the manufacture of a marriage, and improper operation. Self-repair will not hold, if no warranty case, the repairs will cost dearly.

Design electric hobs is quite complicated, however, many of its components have high reliability.

Induction hobs

The operating principle of the induction hob is in direct heating of the contents of dishes, instead of surface plates or dishes most. By reason of, that the cooking surface remains permanently cold such kitchen appliances is very popular.

There are several problems, in which you can carry out repairs induction hob self:

- If the hob does not turn on or off at once do not panic. Current models of the considered products are able to determine the type of cookware, its absence on the hob. Therefore, if the dishes are not suitable for induction heating, or it is not installed, so, triggered protective mechanism. Do not forget about, that induction cookers do not conduct heat very cooktop.

- If low heat, it was originally to be used to check the type of dishes, whether it is suitable for recommendation.

- Repair induction hobs, As in the previous case,, you need to start with a testing circuit for the presence or absence of contact. Fuses often go down, since the network often surges. In this case, simply changing the fuse.

For the rest, repair induction hobs similar to repair of electrical panels.

Required tools

For repair of electric hob and induction hob The following tools need to be:

- Set of screwdrivers. In order to spend many demolition work is necessary to have several different screwdrivers, which may differ in size and type of tip. Besides conventional screwdrivers, should pay attention to the need for an indicator, which detects the presence of voltage.

- Mounting the knife is frequently used for electrical maintenance. Usually, it is necessary to change the length, stripping wire strands and other similar works.

- Pliers are often used for installation purposes. However, they often have sharp parts, which can be used for cutting the veins.

- It is often necessary to have wire cutters to work with wires.

Besides, meter may be required to determine the amount of voltage. It defines the various parameters supplied current. Soldering may be necessary during the repair work.