An interesting technology is gaining popularity in suburban housing construction, based on the use of a unique material - SIP panels. These are products in the form of large-format panels with a multilayer structure.. They are considered very promising and able to compete with traditional building materials..

What are SIP panels made of

In developed countries, the technology of building houses from SIP panels is one of the most popular. Its principle is, that the assembly of load-bearing walls, partitions, floor and slab installation is carried out using the same SIP panels.

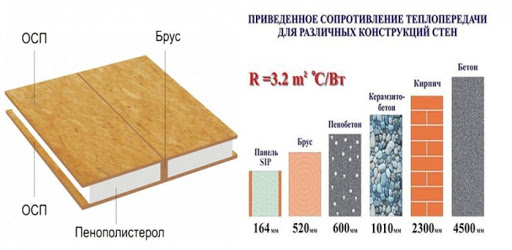

By their design, they resemble a sandwich - they also have a "filling", protected on both sides by OSB boards. Unlike sandwich panels, these products are not obtained by gluing, and by pouring insulation inside. So from relatively fragile materials, an almost monolithic plate with a much higher bending strength and bearing capacity is obtained..

SIP panels are made from environmentally friendly materials, 95% which are made up of solid timber and oriented strand boards. Extruded polystyrene foam acts as a heat insulator inside them, which has higher strength rates, durability and fire safety compared to foam.

SIP technology in Russian conditions

Why is this technology beneficial for the domestic consumer?? First of all, the buildings are very inexpensive: their construction requires half the labor costs and materials, than in the construction of brick houses. Most of the owners of suburban areas, preferring SIP panels, these are people with an average income. Production and construction company "EcoEuroDom" is the largest supplier of SIP panels in the Russian construction market. Acceptable prices for SIP panels from EcoEuroDom.

You can build houses from such lightweight panels on any soil., even in hard-to-reach areas and in those summer cottages, where there are no roads for trucks.

A house made of SIP panels can be used for year-round use. This becomes possible due to the increased thermal insulation properties of the panels.. The walls of such products are warm in themselves., therefore the rooms warm up quickly and cool down extremely slowly.

The durability of houses made of SIP panels is evidenced by the fact, that in Western European countries the age of many such buildings exceeds 50 years old, and they still serve well.

Construction sequence

The construction of buildings from SIP panels can be compared with assembling a designer: a ready-made kit is delivered to the construction site, in which all the details are neatly folded and numbered. Having disassembled the packaging, you can manually drag all panels, since the mass 1 quarter. m of similar products in total 15 kg. Four workers with no experience in construction will be able to handle the installation of walls in just two weeks. At the same time, there is no need to rent special equipment.

A columnar base is suitable as a foundation, which is much cheaper than concrete. No cement is needed to make such a foundation., nor armature.

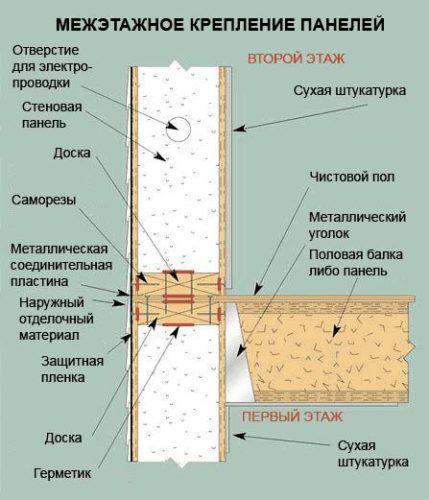

After preparing the base, install the guide bar, to which the two corner panels are attached. Installation of the following panels can be done without careful leveling.

When assembling houses using this technology, SIP panels are joined using a wooden beam, acting as a framework. This principle allows you to get a building, which is three times superior in resistance to wind load and strength of a conventional frame or even a house made of timber.

Walls made of SIP panels are absolutely flat, which further simplifies interior and exterior decoration. No need to plaster the surface for wallpapering. When decorating the interior, any finishing technology can be used, since the walls do not shrink.