- A new kind of floor finishing liquid-tree

- The advantages of liquid wood in front of a stone

- The choice of the board of the (DPK)

- Unlike models decking profile of type

- The difference of surface

- Unlike compounds of type

- Features of assembly of composite decking

- Rules of conduct installation works on laying decking

- The four main rules of installation

- Laying the supporting lag TERRAPOL

- Laying and fastening decking

- Finishing the edges of the flooring and stairs

- Care terrace board

- We recommend that you immediately clean the dirt

Quite often for arbours device, sites, footpaths in the area used the original and easy to install, relatively new universal finishing material- (DPK). The material mimics the natural structure of wood and decorated with designs they have a pretty good view. Mounting slats polymer composite is not much of a challenge, even when working with your hands.

A new kind of floor finishing liquid-tree

If you want to draw a bridge over a stream or track in the garden, make the coating around the pool or on the terrace, you are welcome, Check out the full details of the latest finishing materials - composite decking board.

This new generation of coating, Made from a mixture of plastic (polypropylene) wood meal and extruded. Composite decking board can be used for all kinds of finishing works: both internal, and finishing. A significant part in the composite has chopped wood (order 60-80%, depending on the manufacturer).

The remainder of such additives is filled, as: pigments, polyethylene, UV stabilizers and other.

This material has other names: DPK (wood-plastic composite), liquid wood, WPC (wood-polymer composite). The use of composite boards are widely. It can be used for decoration of terraces, stairways, arbors, tracks, Pierces, playgrounds, patio, pools, balconies, etc.. d.

For example the company "STATE PDK" - narrow profile company, specializing in the supply of decking of the KDP and the installer of composite structures. This material is not just an alternative to other coatings, It is the best solution for processing semi-open areas, recreation areas, facade designs.

But the majority of the old prefer to use wooden coverings for terraces and seating areas by the pool, as well as tile, wood and stone - for stairs, bridges, garden paths. They are guided by the idea, that the use of plastic is not environmentally friendly, in contrast to the use of natural wood and stone. But nowadays polymers everywhere, from tableware, toothbrush to household appliances and other items, that we use everyday.

Consider the advantages of composite decking to wood. Liquid wood is resistant to UV rays, mechanical and biological (bacteria, fungus, rodents, insects) effects, all kinds of detergents. The composite board is not subject to deformation and is capable of withstanding significant thermal swings (from -60 to +80 °C, depending on the model and manufacturer). The service life of the material over 10 years old, and in some cases up 50 years old.

The advantages of liquid wood in front of a stone

Wood-plastic composite is simple and convenient to install and dismantle, It has additional elements (support beams, lies, clips, curbs and so on.). Unlike stone, Composite decking has a non-slip surface and pleasant to the touch. At present, the market of building and finishing materials can be found composite decking manufacturers such, as: Finland, Germany, Canada, Belgium, Russia, China.

The average cost is in the range 1500-3400 rub. for quarter. m.

Positive sides (DPK) and its characteristics:

- environmentally friendly material, easy to process, resistant to mechanical damage;

- fairly easy to maintain and does not require finishing;

- does not rot, It brings great changes of heat and humidity;

- (DPK) durable, service life of not less than 30-35 years;

- Typical dimensions of the slats: length - 1500-6000 mm, width - 135-145 mm, thickness - 22-28 mm.;

- load per square meter - about 800 kg / m2;

- negative sides can be attributed combustibility material.

The choice of the board of the (DPK)

In choosing the material should be paid to its composition. The main components are the following: wood flour, pigments and stabilizers, fillers and polymers. If the percentage of wood flour is about 70%, then the material is not as durable, It does not work well with moisture. The truth has a great view, difficult to distinguish from real wood. Versatile material can be regarded as the ratio of wood flour with other ingredients 50/50%. This composite is more durable, externally stored timber structure. If the proportion is less than wood flour 40% in the composition of the material, then such wood-plastic board is not very different from the plastic in its properties and has a good appearance. Only quite durable and undemanding in operation.

The main point in the selection should be regarded as the, what type of polymer material used in the manufacture. If polypropylene is used, polyethylene, then the surface will slide when walking. At high temperatures can damage the slats air shoe heels. This is not a wear-resistant material. The only plus - low cost. When used in a PVC material, its properties are significantly improved. Surface, even wet does not slip when walking, sunproof, the material is not very flammable.

This kind of good use for decking and platforms around the pool, Pier.

More durable kind, It recommended for finishing of all surfaces. In its polymeric structure of the board can be hollow or full-bodied. Full-bodied best used for exterior work on the arrangement of sites, in the garage or workshop. There has frequent possibility of mechanical damage to the surface. Hollow ideal for devices Balcony Floor, arbors. There's loads on floors are not very large.

Unlike models decking profile of type

Decking Hollow

Hollow - for all types of terraces with low, medium and high permeability, used in cottages, restaurants and cafes. example: Decking Deckron

Decking corpulent

Corpulent - designed for high loads and difficult climatic conditions of use, It is used in places with high traffic, piers and berths. example: Full-bodied board Holzhof.

The difference of surface

Decking embossed woodgrain

Embossed woodgrain - nakatka, imitating wood cut. Minus - low wear resistance. Average embossing disappears after about a year. More wear-resistant embossed only with a deep extrusion (3-D) or a co-extrusion.

Decking grinding

Sanding - Anti-slip treatment (classic corduroy). The most common option.

Unlike compounds of type

Suture - the board is connected by klyaymera (metal or plastic). This is the best way to mount the board. In the operation of the board PDK temperature change expands or, or narrows. Klyaymerov due to the expansion or contraction of the board has a free wheeling. Different types klyaymerov provide clearance between the boards from 2 to 5 mm, that provides good ventilation under the floor.

Seamless - board connects tongue in groove.

mounting Features: It is necessary to ensure good ventilation of the space podnastilnogo; You can only use the method of placing the shield; lag should have free play under the floor ("Floating logs" method). Due to the lack of gaps between the boards and the moisture it evaporates bad if you do not provide good ventilation, the terraced decking eventually deteriorate.

Since in most regions of our country cold winters and hot summers (large temperature swings), We do not recommend using seamless type of board.

Features of assembly of composite decking

The design of composite boards comprises a hollow inside profile. Both sides have the same color, but different corrugation, so as the front can be used by any of the parties. Laying boards must be carried out on the support beams. Suitable as a composite beam, acquired with the board, and wooden beams (lies).

Less composite support beams in the, they are used only on level, solid ground, imeyushtem culvert. Fastening composite board to the support beams as follows. First, the outer edge of the first board is fixed with screws, screwed at an angle 45 degrees. Then set the special clamps on the inner side of the board, and under the edge of each clamp is inserted into the next board. In the end, the outer edge of the last board is fixed with screws. To finish gives a finished look, You can set the side trims overhead, which are also fastened with screws. Caring for liquid wood is fairly easy. Conventional contamination easily removed with a brush, soap and hot water. A melt ice if necessary, calcium chloride, after which the surface should rinse with water.

Rules of conduct installation works on laying decking

Particular attention before starting work on laying decking is necessary to pay attention to the training grounds.

The basis for the flooring can be:

• concrete screed

• sand-gravel cushion with laying on her paving slabs

• support beams made of concrete, wood or metal.

The substrate must be sound, smooth, inclined and frost.

Do not allow the accumulation of stagnant water under the floor.

If necessary lay film (geotekstilь, bituminous carpet) for preventing weed growth.

To drain rainwater and melt water in the case of concrete screed recommended uk

The four main rules of installation

You must abide by when laying decking:

1) Provide adequate air circulation under the cover.

2) to prevent direct contact with the ground structural elements or grassy

3) be sure to take into account the extension of the length and width of the structural elements, caused

temperature difference and humidity during operation.

4) Laying performed at the temperature not lower than +1 WITH. ABOUT

The basis for the flooring can be:

• concrete screed

• sand-gravel cushion with laying on her paving slabs

• support beams made of concrete, wood or metal.

The substrate must be sound, smooth, inclined and frost.

Do not allow the accumulation of stagnant water under the floor.

If necessary lay film (geotekstilь, bituminous carpet) for preventing weed growth.

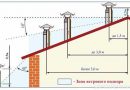

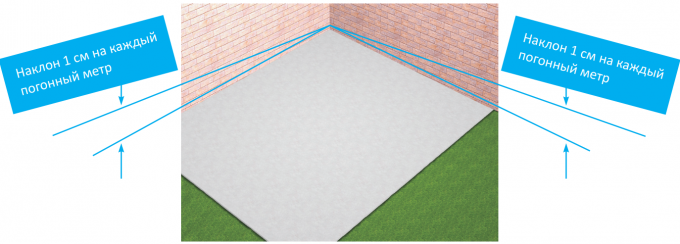

To drain rainwater and melt water in the case of the concrete screed is recommended to make deviations from the static structures

or drainage in all other cases. Incline 1 cm per linear meter.

Laying the supporting lag TERRAPOL

It is a reference Laga, instead of supporting member. therefore, lag must lie on the entire lower surface

basis (concrete screed, paving slabs, etc.. d.)

Fixing joists to the ground is performed using self-tapping screws or dowels, nails in only one place, in the middle

lies, pre-drilled drill hole 3 mm.

If the floor is an open space, where heavy wind, It recommended to use

additional fastening lag, punched mounting band. In this case, mounting tape is attached to ONLY

base.

If you are using decorative strip for finishing ends, the extreme lag laid under section

"Finishing flooring edges and steps" (ris.№2).

To ensure the runoff of rain and melt water, logs stacked along the direction of water flow.

The supporting joists should not be in the water.

For proper ventilation, terraces, WPC decking is laid on the joists TERRAPOL TERRAPOL

50h35h4000 size mm, which are also made of KDP.

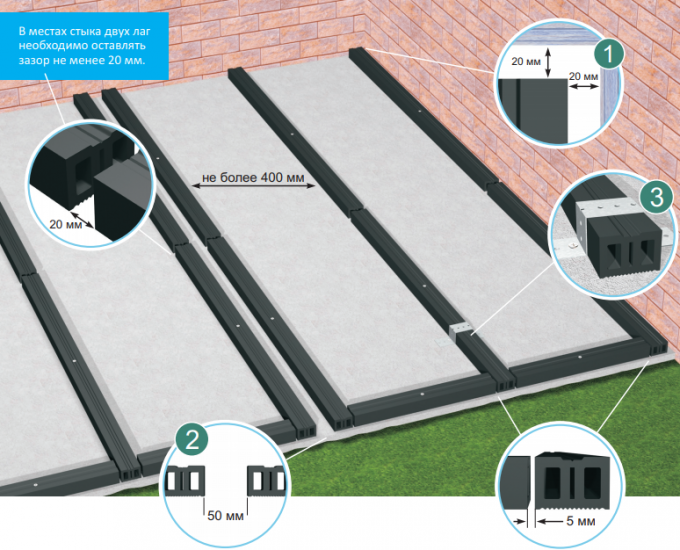

Interval laying lag no more 400 mm.

At high loads on the decking, laying lag interval must be reduced.

Between joists and all static fixed objects (walls, curbs, supports, posts and others.) must

leave expansion joints at least 20 mm .

At the junction ends of the terrace boards necessary to lay two parallel support lags at a distance 50 mm

another other . I.e, the edge of each board relies on its lag. In this case, the board does not overhang more 2 mm.

Laying and fastening decking

Decking is laid on the supporting joists.

Decking TERRAPOL has two working parties (double-sided).

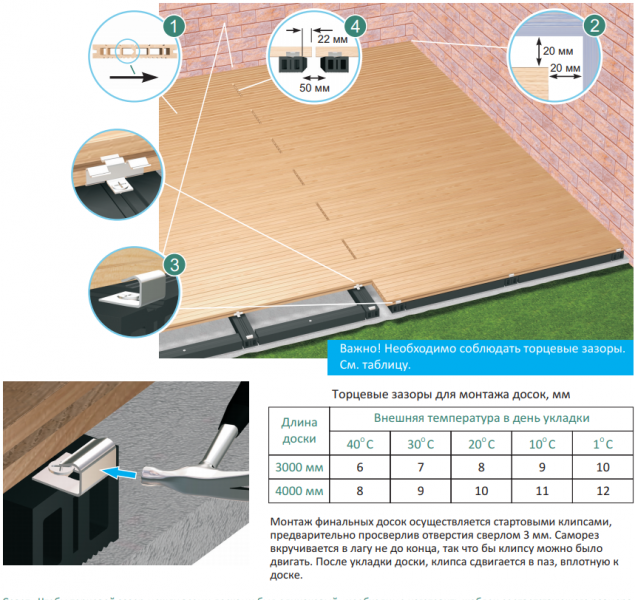

Terrace boards have a directional arrow laying. Arrow seen from the end of the board to obtain a uniform

color floorboard stacked in one direction by the arrow. To create combinations of colors floorboards

stacked chaotically arrows in different directions.

Laying boards should begin from a wall or other fixed structures, leaving a gap of at least 20 mm

For mounting boards to logs uses two types of stainless steel clips: starting and fixing. Home and

Mounting is carried out starting end clip, pre-drilled holes

Fastening clips provide a longitudinal gap between the boards 5 mm. Clips are inserted into the groove of the board and attached

3,5h25 screws made of stainless steel in the groove in the center of the joists. Screws have special notches,

twist without pre-drilling holes with screwdrivers set to minimum

necessary effort.

Boards must be fixed to each point of support on the joists.

Boards installed in the "Extension", offset joints on at least 1/3 board length. Detail of the board must be

length of at least 80 cm, and lie on the joists 3. Thus it is necessary to leave a gap between the ends of the boards, according to

table, for rainwater and meltwater, and to compensate for thermal expansion. The ends of the planks

must necessarily lie on joists and secured to them by means of clips and drill 3 mm.

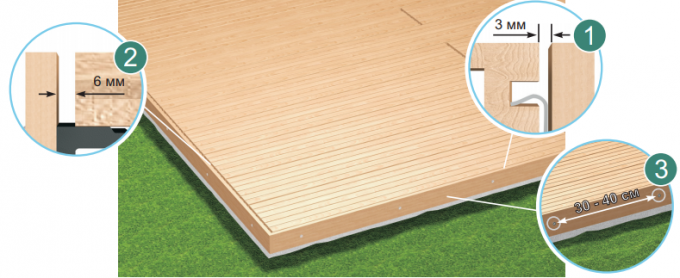

Finishing the edges of the flooring and stairs

For finishing the edges of the flooring is used decorative strip 58h10h3000 mm.

Longitudinal edge of the deck - the side on which the side of the board. When finishing longitudinal edge

the flooring is necessary to leave a gap between the side of the board and the trim strip at least 3 mm

The end edge of the deck - the side on which the ends of the boards. When finishing the mechanical deck edge

you must leave a gap between the ends of planks and trim strip at least 6 mm.

When finishing the deck edges and the edges of steps strap for fastening it to the lag screws from 3,5h25

stainless steel every 30 – 40 cm

When the end parts and corner joints and decorative strips is required to leave a gap of at least 5 mm,

required for thermal expansion

Care terrace board

Read it, to avoid the most common mistakes

• The slope of the base 1 cm / 1 mp or drain.

• joists must lie across the lower surface on the basis of.

• clearance 20 mm lag between the ends.

• clearance 20 mm when laying boards or lag to the wall or another obstacle.

• The clearance of 6 to 12 mm between the ends of the boards, according to table.

• If you used the installation wedges between the boards and walls, do not forget to remove them.

• Boards are installed in the "Extension" with an offset of 1/3 length.

• At the end joints of the edge of each board must lie on its lag and clip attached to it.

• Enough minimum effort screwdriver when tightening the screws.

• Do not place on the surface of the decking heavy objects for a long time, as this

linear expansion may prevent.

Decking Terrapol does not need special care, varnishing and painting.

Decking Terrapol must be periodically washed with pure water with a brush and detergent nonaggressive

(containing no acid). When selecting a detergent pre perform the test on a small surface

boards. If particularly dirty, we recommend using high water pressure (minimoyki Karcher etc.).

We recommend that you immediately clean the dirt

Stains from wine, carbonated drinks, juice and ketchup are washed with clean water.

Stains from oil, mayonnaise, chocolate washed with grease removal detergent.

The spot should be thoroughly rubbed, and then covering all rinse thoroughly with water.

After contact with a burning cigarette or coal to the surface of the board will remain a dark stain, which can be removed

a wire brush.

For finishing the edges of the flooring is used decorative strip 58h10h3000 mm.

Longitudinal edge of the deck - the side on which the side of the board. When finishing longitudinal edge

the flooring is necessary to leave a gap between the side of the board and the trim strip at least 3 mm

The end edge of the deck - the side on which the ends of the boards. When finishing the mechanical deck edge

you must leave a gap between the ends of planks and trim strip at least 6 mm

When finishing the deck edges and the edges of steps strap for fastening it to the lag screws from 3,5h25

stainless steel every 30 – 40 cm

When the end parts and corner joints and decorative strips is required to leave a gap of at least 5 mm,

required for thermal expansion.

https://www.youtube.com/watch?time_continue=47&v = E5QTbBpBDqk

https://www.youtube.com/watch?time_continue=145&v = H4ceqdBFwOo

https://www.youtube.com/watch?time_continue=21&v = 0f0Dk6I4Xrw