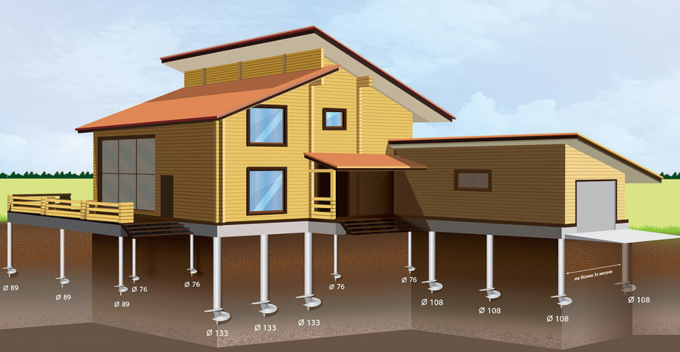

The foundation of the basic construction is its backup, on which everything rests. So to speak, it is a skeleton of the future building. With the help of laying the foundation, you can not worry about the soil or groundwater shifts and deformations of premises, which could cause considerable damage to appearance.

Any expert will agree, that for the proper selection of foundation, you need to carefully consider the options and choose the one, that best fits. There are many types of foundation. The choice falls to the, that is suitable for all indicators, which consider the very beginning of construction. For example, here are important parameters such, composition as a soil or ground water detected. detail, about the kinds and types of pile foundations http://www.domsvai.ru/proizvodstvo/vintovye-svai/

For a long time, It was the most widely used tape base, which is easy to install by yourself or with the help of specialists. Solid base bear a deep soil. With time, many cases have proved, that this type of foundation is extremely unsafe for many buildings.

In this way, in the modern world it is widely used pile-belt or a deep belt type foundation, who are "kicking", on which all the structure lasts.

Advantages and disadvantages of this selection

Not to mention the fact, that this type of foundation is an excellent solution for the weak, boggy and uneven terrain. It perfectly fits even on slopes, which is one of the main advantages in the selection of just such a base. Right to build their own building with extremely easy, if you follow the instructions of the selected instruction.

Benefits pile-belt type foundation:

- You do not need a lot of material, to lay and strengthen the foundation. This saves material resources.

- You can not be afraid to soil shifts, the foundation will stand. No hesitation he is not afraid.

- Withstand a lot of weight, that is ideal for multi-storey buildings.

- It can be installed without the help of experts. Is perfect master, who is confident in their abilities and desires.

- The concrete mix is also preparing yourself, which is very convenient. You do not have to resort to expensive purchases.

Disadvantages pile-belt type foundation:

- It is important to carry out all the necessary calculations for the start of construction. here, more often, it is impossible to do without assistance from the wizard. but, without that it is better not to lay such a foundation.

- The walls of the planned structure should not be too heavy, otherwise possible fracture in abundance and cracks.

- If you plan to finish the basement, any problems with the arrangement in such a foundation.

Sorting pile-tape construction bases

This type of foundation is divided into several varieties, or, so-called, classes. They differ among themselves is, that a form of "feet" (support units) everyone has their own.

It is imperative to choose the right, because it affects not only the appearance, but also the safety of the future construction. Recently popular following classes of foundation:

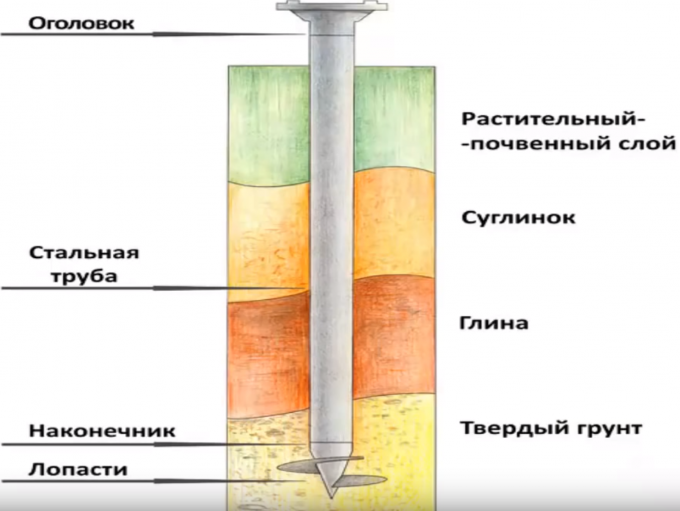

- Pile-screw. He looks like, as a large-scale screw sizes. More often, it is screwed into the ground with the help of special machines and equipment. but, possible laying of a base and self. It is only important to prepare, Having examined all the relevant information about the, that may be required in the process.

- Pile-bored. Used in this case, the beam bored (piling), but the base itself remains tape or pile-belt type. Then the well is being drilled, which is a necessary condition in the packing of a base. Drilling continues until, while rock hard ground do not become an obstacle. The well is then reinforced, after which a filling of concrete mix. All these actions can be played alone.

Deepening piles in the ground

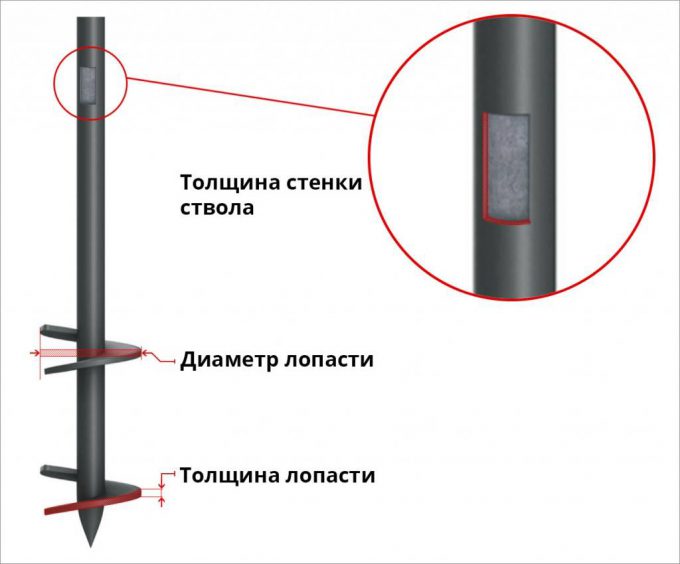

If we talk about the average soils with sufficient bearing capacity, then for small loads to the screw piles include:

- single blade to blade diameter 500 millimeters inclusive, blade thickness to 6 millimeters inclusive and the barrel wall thickness to 4,5 mm inclusive;

- multibladed blades with a diameter up to 300 millimeters inclusive, blade thickness to 5 millimeters inclusive and the barrel wall thickness to 3,5 mm inclusive.

They are used in the construction of individual housing objects and loads comparable industrial buildings. Under the condition of application of the piles with the same parameters under the more severe loading and in a particularly dense soils, It is necessary to increase the structural stiffness of use thicker metal.

To screw piles for heavy loads include design:

- A single-blade diameter greater than 500 millimeters, blade thickness exceeding 6 millimeters and wall thickness of the barrel over 4,5 millimeter;

- with two or more blades with diameters greater than 300 millimeters and a thickness of more than 5 millimeters, the thickness of the barrel wall of more than 3,5 millimeter.

They are used in the construction of large civil and industrial projects.

There is also a point of view, refer to piles that the first or the second group follows the loads, on the basis of the trunk diameter. This is acceptable, but only when it comes to large piles shirokolopastnyh lengths and diameters (more 6 meters and over 159 mm) or uzkolopastnyh stilts. In the case of designs uzkolopastnymi, used in a particularly dense SEASONALLY and permafrost (permafrost) ground, no less significance is the thickness of metal, which stands for the labeling of additional base.

The thickness of the barrel wall

The thickness of the barrel wall screw piles are divided into piles of small thickness (to 3,5 mm inclusive), the average thickness (over 3,5 millimeter) and thick (6 and more millimeters).

The first group (to 3,5 mm inclusive) It recommended for the construction of buildings and constructions of light (arbours, barriers etc.), which belong to the class of liability III (reduced), subject to their use in non-aggressive ground conditions.

The second group (over 3,5 mm) used for buildings, transmitting on the foundation of high load (responsibility Class III (reduced), as well as for buildings II (normal) Class of responsibility but only in areas, submitted by a non-aggressive soils.

During the construction in the medium- and silnoagressivnyh soils and / or under heavy loads (liability classes II (normal) and I (heightened) better to use thick-walled screw piles.

Metal thickness is chosen at the design stage with the data on the corrosivity of soil at the construction site, as detailed in the article "Selecting the barrel wall thickness based on the requirements for durability". To verify the correctness of the selection parameters recommended after the durability test for calculating the residual thickness of the barrel wall in compliance with design loads and requirements GOST 27751-2014

blade thickness

If we talk about the thickness of the blade, now used in the construction of the pile with the blade thickness to 5 millimeters inclusive, and 6 and more millimeters.

As in the case of the wall thickness of the barrel, design, the first group, It can only be used in the construction of buildings and constructions of light, temporary facilities. For long-term buildings, large civil and industrial facilities and for aggressive ground conditions recommended by the pile with the blade thickness 6 and more millimeters. Blade thickness is chosen at the design stage based on the data about the soil corrosiveness.

Coating

The coating provides additional corrosion protection measures by screw piles, because during the installation in the construction of the ground under considerable abrasion. A more effective is to increase the thickness of metal and the use of high-quality steel.

Manufacturers screw piles are mainly used the following coating:

- polymer;

- primers enamel on rust;

- polyurethane;

- epoxy;

- tsinkovыe (obtained by hot or cold galvanizing).

But it is undeniable, that the coating while maintaining its integrity can reduce the negative effects on the aboveground part of the pile and on land in the contact area "atmosphere - soil".

Video on pile foundations