Modern gas-fired boilers and pragmatic pursuit of power system solutions to progressive heating issues in a private home ownership, apartment are increasingly leading to the use of closed heating systems with forced circulation of coolant. Closed loop fluid circulation can increase the operating pressure of the system and thereby improve its safety because we know, that with increasing pressure in the liquid medium rises its boiling temperature. In particular, water characterized by the following ratio: 1 atm. – 100 degrees, but 2 atm. – 120 degrees.

Condition monitoring system liquid filling is carried instrumentation. First of all, gas-fired boilers, equipped with a circulating pump and safety group, suggest a mechanical or electronic display dial, readings reflecting the temperature and pressure sensors, located at the boiler outlet conduit (filing). Additional pressure gauges installed on distribution manifolds, responsible for supplying coolant to different parts of (floors) structure. No indications auxiliary gauges not dispense system comprising boilers or combined indirect water heating, as well as complex systems, using a high-temperature circuit - heating and low temperature radiators - warm floor.

The pressure in the system drops

We call causes, that answer the question, Why drop the pressure in the heating system, and suggest ways to address them. so, the reason for the negative effects are:

- unauthorized coolant drain pipes at the joints with the radiator or directly to the main pipelines gust, seal failure pipes warm floors;

- failure directly heating unit, caused the formation of microcracks in the heat exchanger housing;

- breakage blasting membrane type valve, entering the boiler equipment security group;

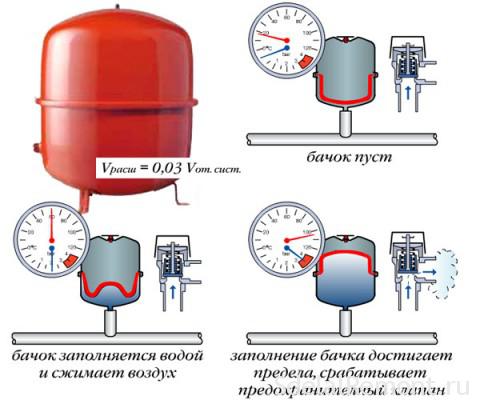

- Membrane rupture in the expansion tank, to compensate for linear expansion of the coolant by increasing the temperature;

- depressurization of the hot water circuit (DHW) in the embodiment bithermal heat generating installation, hence pressure drops in the two-circuit boiler during intensive analysis hot water and rises sharply at its termination.

Determination of coolant leaks

Leakage is determined initially by visual inspection, for this, usually, feed system to the recommended level and stop the forced circulation of liquid. Particular attention is drawn to the shut-off and control valves, installed on heating radiators, their direct connection to the main pipe. If you can not identify yourself, what is dictated by pressure drop in the heating system, then use the services of specialists. With the pressurization air is achieved more intense release coolant leakage at places. Sometimes you just want to remove the connection to repack or replace the defective fitting. Device requires a more complicated definition of a gust hidden in the wall of the tubes or "snail" water floor heating. To do this, we use special scanners, determining with high accuracy the concentration of excess moisture. Next business equipment: dismantling decor wall or floor surfaces, recess damaged area and replacing. means eliminating potechek for heating.

pressure drop, associated with defects of the boiler equipment

If you set, that pressure falls in the gas boiler, then to troubleshooting involved only employees of the service organization, on the balance of which is a heating unit, as a high-risk instrument. Qualified service center staff will offer several solutions to the problem: perform soldering or replace the entire heat exchanger. All will depend on the nature of the damage, resulting from the regular flushing of heat "shirt" boiler from scale, factory latent defect or banal operational wear. After work specialists made appropriate records to conduct warranty and post-warranty repairs. defining, that falls in a two-circuit pressure boiler due to damage to the rubber membrane expansion tank, necessary to carry out the replacement of spoiled goods to the new tank, to not be subjected to any additional risks of heating system, that arise after the feeding system to a specified level. Liquid, lost opportunity for the linear expansion, will cause the, that the pressure in the loop will rapidly increase, causing frequent safety valve. damage to the diaphragm (EPDM) the safety valve triggers the protective function of the device even in cases, when not reached the maximum pressure in the heating system, ordering the emergency discharge of excess liquid from the circuit.

The pressure in the system exceeds the recommended threshold

That fact, that increases the pressure in the heating system, It indicates the presence of one of the reasons, are in this list. so:

- drop observed at a certain contour area - stopped after circulation control devices;

- Continuous replenishment system is carried out;

- stop valve cuts off the entire contours or portions of main piping;

- let, making it impossible to circulation of coolant in the system because of the critical concentrations of the air mass;

- mechanical blockage installed in the circuit heating systems and devices for filtering fluids.

Troubleshooting due to the consistent study of the entire space heating circuit. As a result of oversights, tampering curious children, possibly, valve overlap, zadvizhek, ball valves. It can also affect the adjustment device off from the mains (servo motors for the collector or three-position thermostatic taps when connected DHW circuits in combination boiler). Resort to preventive flushing Veins mechanical filters. Particular attention is self washing filter, which are mandatory for the old heating system, which uses iron heaters and metal pipes of large section. Produce crimp heating system, and replacement apparatus for automatically venting if necessary, produce faucet repair, responsible for feeding the heating circuit of the boiler.

In this way, continuously maintaining the working pressure in the heating system 1,5-2 atm., We are able to use heating equipment safely and effectively, We achieve optimal physical load on the devices and heating pipelines, thereby increases their trouble-free operation.