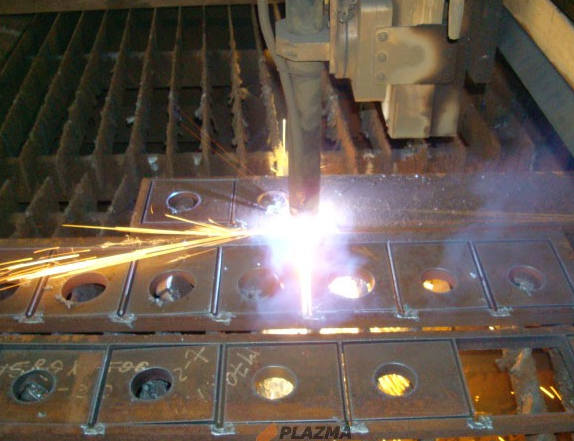

Metal processing means by the application of various technologies and equipment. It is gaining popularity use art plasma cutting metal. What are the advantages and disadvantages of this method? What are the features of the technology, building machines and how they work?

Process for metal cutting

plasma jet dot heats processed pressurized material 6-8 atmospheres. Vary depending on ispolz% D:

Air-plasma. This approach differs low cost due to the availability of air from the environment. Scope apply to virtually all types of metals. The result is of medium quality and maximum speed can not be called.

Oxygen cutting allows us to achieve higher performance relative to neat edge and speed. When the cut perpendicular to the slag is minimized. Especially it concerns the underside of the fabric.

The use of protective gases gives the maximum of. This approach applies to professional equipment, which is worth several million. The metal sheets with the thickness may be up 300 mm. The use of plasma cutting makes it possible to manufacture products of stainless steel sheets, with a thickness of up to 50 mm and alloys of various ferrous metals.

If we compare the plasma cutting with the other options on the equipment, in any case, the product will be of high quality and precision. therefore precision plasma metal cutting any complexity became readily available.

It is growing in popularity gaining technology art plasma cutting of metal to create a variety of decorative elements.

The peculiarity of the art cutting pattern with small elements is, that the cutter is moved from one edge of the article to the opposite.

At first glance, it is illogical, but not to work with the heated metal. If time saving%, then will save it to the second, required for cooling the metal. In this case, the shape cutting process will be longer.

If a shape cutting technology on the programmable machine all clear, then the master operating manual plasma torch cutting technique will have to work out by trial.

The advantages of plasma cutting on CNC machines

Complex geometric and floral ornaments in art metal, Rappoport cat, from under the hand tool can come up with a few differences. The reason for this can serve as a trembling hand of a master, flame random delay in one place. The NC machine program is entered art technology for applying each element. The flame is extinguished, then it lights up again, but only at the moment, when the cutter is moved to a predetermined point.

plasma cutting, This flexible serial production of metal products

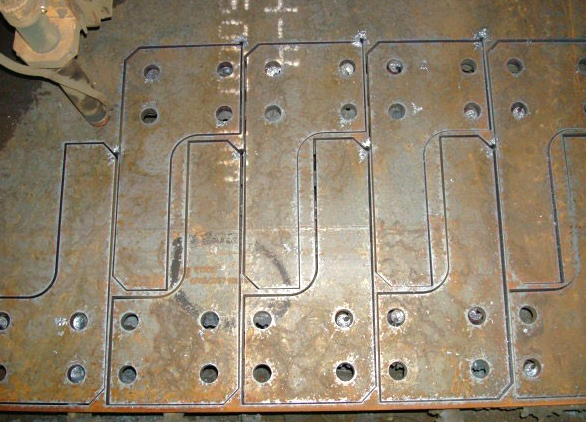

Plasma cutting of metal, possessing good performance repeatability of hardware, It has a remarkable quality, this, as a flexible change of series metal production.

Production of metal products on machines plasma cutting machine, It makes it possible to produce absolutely identical parts from one piece to hundreds or thousands of copies, without loss of quality, characteristic for machining. EXAMPLE good repeatability in the manufacture of decorative elements exterior plasma metal cutting method.

It is worth noting, that mass production of metal parts using cutting metal plasma technology, significantly reduces the cost of the final metal. So, with significant volumes of metal procurement, from which the series part, purchase of metal price declines. Universalizing metal processing for similar parts, increase the production capacity of metal, by plasma metal cutting, factor of. Reducing the cost of packaging production parts and the cost of loading and unloading operations.

advantages of the technology

Having considered the working principle of plasma metal cutting are the following merits:

- Very high performance;

- the finished product has no deformations due to local effects of temperature;

- there is a possibility of formation of parts of any complexity with respect to the product configuration;

- It does not require careful additional processing due to the absence of large sagging hot metal;

- minimal waste with proper cutting;

flexibility on the types of material being processed.

Besides, process different safety and the ability to configure the serial nature of the production. Products are 1 accuracy class.

disadvantages

If we talk about the disadvantages, the question will relate for the most part non-ferrous metals. However, there are general indicators:

- limitations regarding the thickness of the processed sheets;

- purity cuts for the burner outlet;

- stringent requirements of the squareness of cut (deviations are allowed no more than, than 5 degrees depending on the parameters in the job and material);

It prevents the use of two cuts simultaneously using 1 apparatus.

Significant value can also refer to the shortcomings. but, High capacity%.

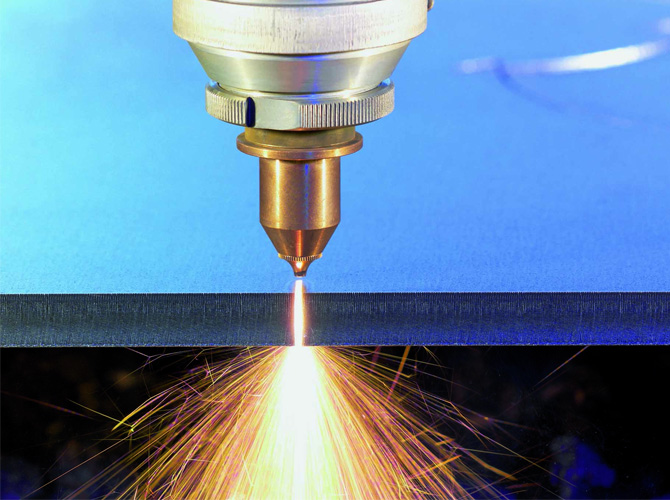

The principle of the appearance of plasma

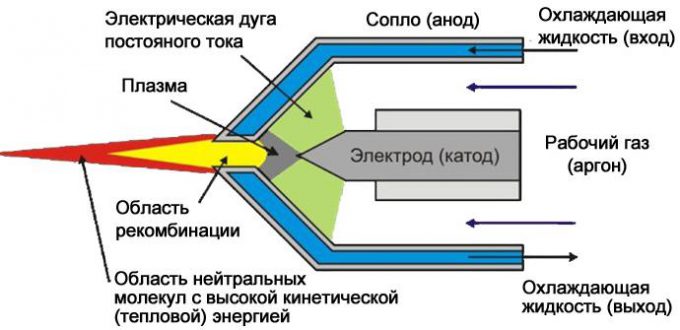

The plasma jet is formed as follows:

Electric arc. Is formed between the electrode and the nozzle assembly (or%). Temperature at this index reaches a 5 thousand. degrees Celsius.

The gas supply is combined with the arc temperature raising process up to the 20.000 degrees.

The jet plasma formation occurs due to ionization gas. When this temperature reaches component 30.000 degrees.

Externally, the result looks like a bright glow, which exits the nozzle at a rate of 500 to 1.500 MS. It is this flow and is made of the metal sheet thickness before cutting 20 mm. The additional polishing product is virtually eliminated due to the high efficiency of plazmoreza.

As for gas, in practice different variants are used:

- ambient air;

- technical oxygen;

- nitrogen;

- argon;

- hydrogen.

It can also be used pairs, which is formed during boiling water.

Design features of equipment

devices. A first embodiment is used for Industrial purpose workspace. Portable units can be purchased for private use, because it is allowed to use at the construction site.

The range of vehicles is also based on 2 types of plasma:

indirect action, that is, a non-contact manner. Such units are used cutting materials, which do not belong to the metal.

Direct action, direct contact. In this case, the cutting arc is formed between the electrode and the workpiece, allowing the heated gas to the jet gap. Poe%.

Interconnected units may vary slightly. However, there is a standard set of devices for plasma metal cutting:

- power supply with valid values, which are required for a particular device;

plasma generator; - cables and pipes for supplying necessary power in the form of electricity and gas;

gas bottle; - compressor, allows you to adjust the speed and pressure of the cutting issued strui.Plazmot%:

- nozzle;

- electrode;

- gas supply channel;

- cooler;

- an insulating cap, which is able to withstand high levels of operating temperature.

The equipment is designed as a sophisticated device, which is characterized by an impressive array of benefits. Chief among them are high quality and exact repetition of%. In this case, the speed of execution of the order is also characterized by short periods.

The order value of work

EXAMPLE prices for plasma metal cutting an example of hardware "PLASMA SPB" plant

|

sheet thickness |

STEEL BLACK; (rubles in n / m) |

stainless steel, RED (rubles in n / m) |

|

3 mm |

19.00 rub. |

26.00 rub. |

|

4 mm |

21.00 rub. |

35.00 rub. |

|

5 mm |

24.00 rub. |

42.00 rub. |

|

6 mm |

28.00 rub. |

52.00 rub. |

|

8 mm |

38.00 rub. |

79.00 rub. |

|

10 mm |

48.00 rub. |

110.00 rub. |

|

12 mm |

58.00 rub. |

156.00 rub. |

|

14 mm |

69.00 rub. |

232.00 rub. |

|

16 mm |

79.00 rub. |

271.00 rub. |

|

18 mm |

88.00 rub. |

338.00 rub. |

|

20 mm |

119.00 rub. |

396.00 rub. |

|

22 mm |

139.00 rub. |

560.00 rub. |

|

25 mm |

149.00 rub. |

707.00 rub. |

|

30 mm |

229.00 rub. |

936.00 rub. |

|

32 mm |

324.00 rub. |

948.00 rub. |

|

36 mm |

349.00 rub. |

972.00 rub. |

|

40 mm |

379.00 rub. |

1056.00 rub. |

|

45 mm |

419.00 rub. |

1122.00 rub. |

|

50 mm |

489.00 rub. |

Negotiable |

|

60 mm |

635.00 rub. |

Negotiable |

|

70 mm |

780.00 rub. |

Negotiable |

|

80 mm |

810.00 rub. |

Negotiable |

|

90 mm |

850.00 rub. |

Negotiable |

|

100 mm |

890.00 rub. |

Negotiable |

|

110 mm |

950.00 rub |

Negotiable |

| 120 mm | 980.00 rub | Negotiable |

| 130 mm | 1080.00 rub | Negotiable |

| 140 mm | 1140.00rub | Negotiable |

| 150 mm | 1190.00 rub | Negotiable |

| 160 mm | Negotiable | Negotiable |

| 170 mm | Negotiable | Negotiable |

| 180 mm | Negotiable | Negotiable |

| 190 mm | Negotiable | Negotiable |

| 200 mm | Negotiable | Negotiable |

| 210 mm | Negotiable | Negotiable |

| 220 mm | Negotiable | Negotiable |

| 230 mm | Negotiable | Negotiable |

| 240 mm | Negotiable | Negotiable |

| 250 mm | Negotiable | Negotiable |

| 260 mm | Negotiable | Negotiable |

| 270 mm | Negotiable | Negotiable |

| 300 mm | Negotiable | Negotiable |