Everyone aspires to, to live in a cozy and comfortable room. But for this purpose should be to produce a quality repair. Each of its stages requires attention and diligence. One of the main is base alignment sex for subsequent flooring flooring. But before the screed should produce high-quality waterproofing. She performed in front of the screed floor and prevents errors in installation.

designation

The first and primary function of waterproofing floor - protective. It does not allow moisture to penetrate the slab, and also does not allow moisture inside the cast solution, which can result in the initial stages of an uneven drying, cracking and peeling.

Furthermore qualitatively executed before the screed floor waterproofing improves strength itself screed. Waterproofing causes, the solution dries slowly, process is somewhat slowed down. This allows it to gain better strength and not allow to appear different defects on the surface. If you do without this layer, it may have to follow up with a solution after pouring: closing film of polyethylene, periodically wet.

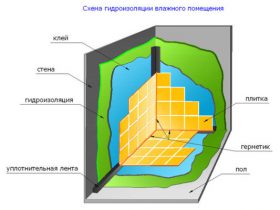

Waterproofing is arranged in each case, if there is a probability of moisture. This applies to such facilities as a bathroom, kitchen, bathroom. The floor must be completely insulated, since there is a high probability of accidental flood.

From specialists constantly receiving mount recommendations waterproofing layer even in living rooms. This is due to the fact, that in the resulting solution for filling contains a certain amount of water. She is in the process of drying can seep into the floor slab, after you get to the neighbors from the lower floors. Instead of the full waterproofing, made use of the material in the ground slab joints. In most cases, this is sufficient for full functioning layer.

Waterproofing important to the apartment under the screed on the ground floor. If the screed will coexist with a wet and cold air from the cellar, the benefit she will not do. The process of destruction of the concrete base will go much faster.

This step is mandatory for private construction. Without waterproofing layer the moisture will penetrate the walls and the floor, lowering their temperature, and gradually destroying. Over the life of the additional cracks may appear, that will only grow. No harm will even arrange two waterproofing layer: before and after pouring the solution for floor screed.

Kinds

In the construction market, you can find a huge amount of material to perform high-quality waterproofing layer. This leads to a difficult choice of a particular variant. With the more they will appear more and more over time, It has its pluses, and cons. The main types of waterproofing materials:

- Rolling. But interest in them is reduced due to the fact, that they have little lifetime. Consequently, if a person has decided to live in one place for a long time, you should think about other stuff. its two main subspecies can be identified - and fusing Okleechnaya. In the first case it is sufficient to fix the roll on the ground and are ready for further work on screed, and in the second - to use additional means to heat the bitumen, available as part. This construction of the burner may be, working on gas.

- hydrophobic mastic. They have a kind of liquid and they are based - bitumen. Mastic is easy to apply the usual brush, how to paint. Despite, that the cost of such materials insignificant, their lifespan and reliability during operation have low rates. Simply pay attention to the alternative - bitumen-polymer mixtures, which are able to withstand low temperatures.

- plasters. Their appearance can be noted recent time. They are presented in dry form. For use mixture diluted by the necessary quantity of water, to get the consistency of condensed milk. For the application of generally used trowel. Mixtures have a specific composition: sand, Cement, polymer components. Once the mortar dries, we obtain a covering, able to withstand a shock, and deformation.

- penetrating waterproofing. It refers to the number of not only new, but also more effective means for sealing the device layer underneath the apartment floor screed.

After application of the existing components in the mixture react with the concrete surface. As a result, formation appear crystalline, which do not dissolve. All having pores at the base of them are closed, It creates a reliable barrier. Even if moisture will try to penetrate under pressure, then chances are it will not, as such waterproofing floor screed It has a high level of counteraction. Further dry mixtures, they are marketed in liquid form.

After application of the existing components in the mixture react with the concrete surface. As a result, formation appear crystalline, which do not dissolve. All having pores at the base of them are closed, It creates a reliable barrier. Even if moisture will try to penetrate under pressure, then chances are it will not, as such waterproofing floor screed It has a high level of counteraction. Further dry mixtures, they are marketed in liquid form.

It is worth noting, that each individual type of material for the device waterproofing layer has its specific application and process of work. It should therefore be find out more.

roll materials

As for the order of performance of works on the device of roll waterproofing, the first thing is training base for subsequent installation. Even slight surface cracks, and bumps are to be embedded with a solution prepared from cement and sand. After drying dust and dirt is removed. For better adhesion use bitumen emulsion. It is primed base. If desired, a better quality waterproofing layer, further processing performed insulation penetrating compositions.

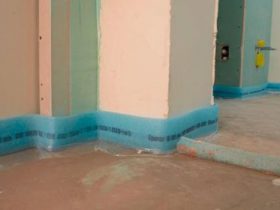

We can not forget about the damping tape, which is fixed on the perimeter of the room, where work will be carried out by pouring the screed for leveling base. The tape helps to compensate for the future expansion of the fill, depending on changes in temperature.

When all the above is satisfied, you are ready to roll flooring for waterproofing. Thus each succeeding roll sheet should overlap by approximately the previous 10-15 cm. The same applies to walls. Subsequently, it is easy to cut off all or closed screed. For a better quality, the number of layers increases. But then, should be done laying the waterproofing rolls offset new joints.

Welding joints between the sheets and used a building dryer. Its efficiency is high and sufficient for quality of work. Do not worry, If there are bubbles on the surface or wave. At these sites the upper portion of the sheet is pierced with a knife, and air is driven out. Edge in the future are coated with mastic and carefully pressed against the base.

This option is not waterproof high cost, It has the required level of reliability and availability. But the installation process requires a lot of effort. Highly susceptible to mechanical damage.

The use of mastic

At the initial stage it should also remove all the debris and dust. This can lead to uneven settable mastic base. The same applies to oil stains, capable of destroying the waterproofing layer. cusp, detachment must be downed, after embedded in the required amount of cement-sand mortar.

Thereafter, the primer processing is for improving the adhesion level. It is best to acquire all the material and equipment to work from a single source. After application to the surface should be given time to complete drying (about two hours). No harm will pay attention to the information, which is displayed on the packaging of a primer, which indicates the exact time.

Acquired by means of several layers applied to the surface for grout. It is worth noting, that a subsequent layer of mastic must be applied after 3 hours after the last, but not later than 6 hours. after 6 hours most of the starting material of polymerization process.  If you pass this time, then a new layer begins to delaminate. Direction should not be changed for one layer, but redirected for later. This improves the reliability level floor waterproofing in the apartment before the screed.

If you pass this time, then a new layer begins to delaminate. Direction should not be changed for one layer, but redirected for later. This improves the reliability level floor waterproofing in the apartment before the screed.

mastic Drying takes place after two days. It was during this time should not be made any other work, to avoid damage to the waterproofing layer.

Mastic as a material different ecological cleanliness, fire safety, It does not require a large number of tools to work. But has, in turn, and a significant drawback - low resistance to mechanical damage.

plasters

The process of installation of the waterproofing layer when using such material does not take much time. Suffice it to prepare a solution of the dry mixture, adding the necessary quantity of water, then apply a first layer. minutes later 15 thereafter (dries as a layer) is applied to the second layer. This uses the opposite direction for applying the previous layer. All usually done 3-4 layer. Everything will depend on the desired result and premises, where waterproofing is arranged for floor screed in the apartment.

Once the mixture is applied to, during the day it should be wetted for uniform drying. Overall, the drying process is about two weeks. It depends on the type of mixture. No mechanical influences she should not feel.

Low cost and ease of application mixtures prepared for waterproofing continuously struggling with the main drawback - lengthy drying period, which is not always advantageous to carry out repairs in the apartment.

penetration (capillary) waterproofing

Waterproofing under floor screed can be performed by penetrating compositions. Among the features of the works of such material can single out the preparatory stage. There will be a fairly simple cleansing and smoothing existing cracks. The entire surface must be thoroughly wetted with water. Must be observed in this measure - the water does not get to the neighbors.

If used in the dry composition, then it is added to the required amount of water according to the instructions. produced surface wetting, and to direct application of a ready mix.

When applied to the first layer of waterproofing under a coupler in an apartment, bides time, prescribed in the instructions. After that the surface is wetted again and applied a second layer.

Prior to the final drying surface constantly moistened. The plastic film can serve as a helper, waterproofing layer which is covered. For additional insulation can be treated and the very tie.

This all can be called basic methods of waterproofing to the floor fill. All in all, their market represented a huge amount of, among which may be mentioned liquid rubber, castable and other. Everything will depend on the amount of finance, customer preferences.

For a better quality of the insulation layer, it is recommended to use multiple methods. Each of them will provide the surface of their properties and quality. But do not skimp on materials, because from them will depend on the durability and quality of the floor.