Old concrete floors over time show negative qualities. It can be cracked, potholes, chips and other defects. You can embed each hole separately, and it is possible to implement a thin layer leveling floor. These compositions have a sufficient number of positive qualities, which can dry within a short time, and can proceed to the finish trim. In addition, the strength of the base get even better, than for concrete pouring.

Advantages and disadvantages

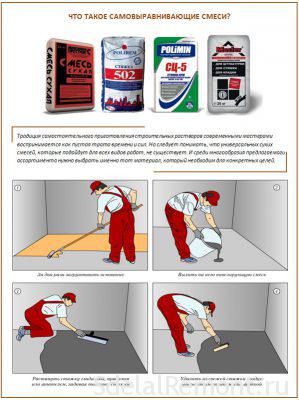

The use of self-leveling compounds in the work does not create any difficulties. They are very simple and easy to mix: It is added to a mixture of the required amount of water, then is poured on the floor surface. Potholes and defects filled completely, and creates a level surface. In addition, there is another set of positive qualities:

- Quick drying process, which is very important with a limited amount of time to repair.

- A very thin layer of the final, that is markedly different from other kinds of ties. On average, it can reach the 5 mm. This quality is very important in rooms with low ceilings.

- A few hours after potting mix on the basis of it you can move around and perform all kinds of finishing works in the room.

- Shrinkage in such a coupler is not shown, but it remains a very robust and reliable design. It has a long service life.

- Novice under the force to carry out alignment Floor thin layer. Self-leveling floor will turn out perfect without experience.

- One day after the device self-leveling floors flooring can produce any type of floor covering, that is, to carry out finishing.

but any technology can not do without the drawbacks. true, most of them are associated with the process of the pouring. If you adhere to the requirements and recommendations, then they can be easy to get rid.

- The surface must be prepared carefully. There must be no defects, whether it is cracked, potholes, significant irregularities. It should also be on the surface of dust and dirt.

- It is very difficult to make the dismantling of self-leveling floor, if the work was not qualitatively

- By the complexity production process You can also add high value products.

- a large amount of toxic and noxious substances liberated during drying to human health. If skin drops finished mixture may appear burn. In addition, the very high level of flammability.

This all indicates that, that care should be taken when using mixtures self-leveling floor and conduct all work strictly according to the instructions and recommendations from the manufacturer.

Application area

The main purpose of the application self-leveling compounds - a device of a thin layer in the alignment base screed. There are more specialization, which include dusting the surface, the primer, improve the surface quality, which is processed and more. It is worth noting, that fast drying does not allow to appear on the surface and form shrinkage cracks.

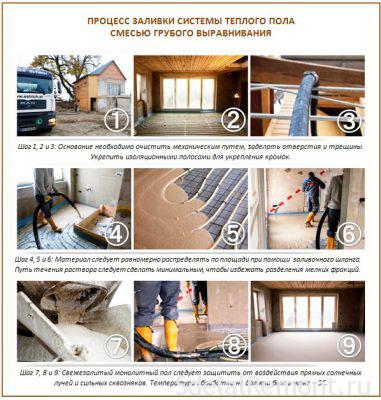

There is a concept of gross rovniteley. With their help, largely arranged subfloor, even if, If the screed is laid underfloor heating system. Here the requirements to the mixture even less. Yet we take the maximum measures to obtain the desired result.

Types mixtures

Different composition suitable for each particular base. It is important to pay attention to some points, allows you to make the right choice:

- The level of humidity in the room, where it will be used floor leveling technology self-leveling compounds.

- The presence or absence of additional decorative finishes subfloor.

- The presence of direct contact with water during operation. It deals more with such premises, like bathroom, kitchen or bathroom.

- Additional quality surface arranged. This number is usually referred noise absorption, insulation layer device, confrontation slip while walking.

- The impact on the subsequent floor surface chemicals for washing, that is, the use of various household chemicals. It is inherent in the kitchen areas.

- Using a mixture is floor leveling a thin layer or it is already finished surface finish.

- only reason, which will get self-leveling floor, its characteristics and moisture level.

For all these reasons, secrete certain kinds of dry mixtures for qualitative alignment subfloor.

For any premises suitable mixture based on cement. The layer thus obtained maximum thin, marginally 2 mm. Here is a great option - self-leveling floor "Prospectors". This reduces the drying period of the surface. Final finishing can begin to do almost immediately. If necessary, you can select the corresponding mixture and to fill an 5 cm. They will be more expensive than the cost, what example, mixture of gypsum-based. You can select a product «Ceresit» Company, «Knauf».

As for gypsum leveling compounds, they may be used primarily in areas with low levels of humidity. Immediately should move aside the bathrooms or kitchen. When you select should focus on the production of "Volma", «Europlan». Tie layer is somewhat greater when using gypsum mixtures - by 20 to 100 mm, that has an impact on the increase in the drying period.

The mixtures may be based on epoxy resins, that during operation have improved abradability. When external forces on the surface of cracks and gouges. They can go for chemical laboratories, but not for the kitchen or bathroom.

Increased cost and requirements to the base has Self-leveling polymer-based. But here exhibit the characteristics are of interest even for experienced professionals. When arranged self leveling flooring mixture must comply with them fully, depending on the operating conditions. Here we can distinguish such manufacturers, how "Osnovit», "Ruslan", «Forman», etc..

Besides, there is a division of mixtures arranges tie layer. allocate Thick, special, quick-hardening and finishing. Each of them has its own characteristics, including, of drying time. Everyone's strength to answer the question, as a self-leveling floor pour thick layer. All will depend on the fraction used in the blend and target, to be achieved.

Required tools

Before starting work, should be reserved tool. Everything will depend on the complexity of the work, type of material used and the desired result. at finish leveling subfloor should be available:

- capacity, which will be kneading solution.

- Drill beater type mixer, by means of which to prepare the mixture with water.

- Putty knife, allowing to spread evenly over the surface of the solution. Despite the flow properties and self-distribution mixture on the ground floor, This tool will be very useful, to get high quality.

- Following the results of pouring on the surface may appear in a bubble of air. Of them should be disposed of using the needle roller. Otherwise, after drying will form 'craters', creating a negative manifestation of the whole structure.

Substrate preparation

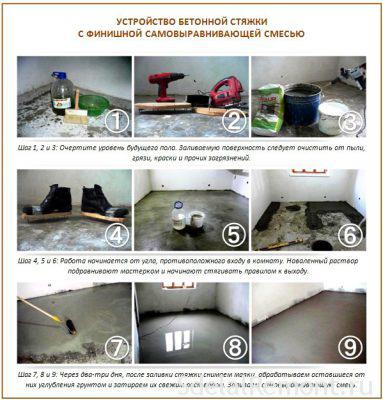

Due to the presence of all the equipment and material to work, you can begin the preparatory activities. No cracks and potholes on the basis should not be. Through them, the mixture can flow downstream and fall on the floor, as well as to break the overlap. To eliminate them, a special putty. An alternative to this method - a device rough floor screed. Removing the old coating is subject to removal, paint on the surface elements, varnish, garbage, etc..

Leaving even a trifle on the site to fill self-leveling floor, the latter will be spoiled if not totally, but partially. We'll have to dismantle, which in addition to the financial component and takes a lot of time.

to apply self-leveling compounds perfect foundation, having a height difference to 30 mm. In addition to this, there should be no serious defects. A solid foundation and confidence in it is in the case, if pre-arrange a subfloor.

You can not forget about padding ground. This item refers to the number of mandatory, and can not depart from it. Self-leveling on the dirt road to go to not only exactly, but also more reliable engages with him. Finishing surface quality thus will reach the maximum effect.

There may be cases, When the primer is absorbed into the ground. In such a situation will have to repeat the procedure again, i.e. apply another layer. It is worth remembering, that subsequent layers deposited during the previous full drying.

This all training conducted before, as align curve screed. When the work closely follows technology, you can be sure of a positive final result.

kneading the mixture

The most important thing at this stage - to strictly follow the instructions, which is listed on the packaging of a self-leveling mix.  Manufacturers know all the details of their products and suggest artists, how exactly all perform to obtain high-quality surface. All the proportions must be observed without deviation. This will avoid possible difficulties in the future.

Manufacturers know all the details of their products and suggest artists, how exactly all perform to obtain high-quality surface. All the proportions must be observed without deviation. This will avoid possible difficulties in the future.

If you get a liquid formulation, the properties and characteristics may be lost. Perhaps even the appearance of cracks on the surface, and also chipping and dents from external influences.

The mixture should be backfilled into the water, instead of doing everything in reverse order. Otherwise, the process will take away a lot of time and effort. Kneading should be no rush, eventually getting dense working solution.

Pouring the mixture

Distribution of solution will depend on, a base in front of us. Wood Floor screed thickness will be from 5 to 20 mm, and all other minimum we can take 2 mm self-leveling floor. This should be considered a low-ceiling location. Besides, when the self-leveling floor is arranged filling height should completely cover all grounds of error. This is why they are used.

After distributing the mixture over the entire plane indoors, should go spiked roller, to get rid of the bubbles formed. To avoid damaging the fill layer, Wear suitable shoes - kraskostupy. In the end, it will only have to wait for time to dry completely self-leveling floor. the main thing, avoid direct sunlight on the surface, lest there be premature drying.

At the end of the work need not grind the surface, to care for him and subsequently further align. Paul is perfectly flat.

For large areas should not be ready to fight a large number of mixture. It quickly thickens and dries in half an hour. Consequently, better fill one section, and then proceed to the second, than throw solution without. No differences between the freshly poured screed is cast and will not.

Professional advice

When large areas of casting self-leveling floor more 20 square meters, it is necessary to perform the expansion joints. They must be completed within the first three days of drying.

Self-leveling mixtures are not used for plywood or wooden base. But if you arrange it on the basis of a separation, which may be a film of polyethylene, then no problems will arise.

Drying time will fully depend on the type of mixture used in, as well as environmental conditions. At the time it affects the thickness of the fill.