Each seeks to obtain the highest quality floor construction. But for this it is necessary to perform properly and in compliance with the installation technology. All functional and aesthetic characteristics are inherent in the room in which case. For laying on the floor base only recently started to be used drywall rather GVL ( gypsum fiber sheet), which appeared in the technology company Knauf. It is unnecessary to be confused with conventional drywall sheets GCR- it is quite another matter.

material benefits

When the device floors using plasterboard, more precisely GVL, you can get a whole range of positive attributes, which include:

- All work "dry" method. That is no wet processes will not. The room will be maintained normal levels of humidity during the entire period.

- Laying plasterboard on the floor can be carried out on its own, without the involvement of specialists.

The entire installation takes a long time and is very simple for the initial execution of novice builders.

The entire installation takes a long time and is very simple for the initial execution of novice builders. - Acts as a heat and sound-proofing material.

- To process the material is very simple. He easily subjected to cutting, Sawing, as well as other processing methods and techniques.

- low weight. It does not give a serious burden on the slab, and also to arrange logs on a wooden base. It does not matter here drywall device in several layers. As a result, it still turns a small weight design.

- The low cost material as compared to other embodiments of the device smooth floor. This is to some extent and attracts most of the performers.

- after graduating Works on drywall you can make any kind of laying the flooring. It is possible to perform all without pretreatment due to the fact, it turns out really smooth surface, corresponding to the horizontal level.

But this is just a basic list of the pros, that has drywall when laying on the subfloor for qualitative alignment.

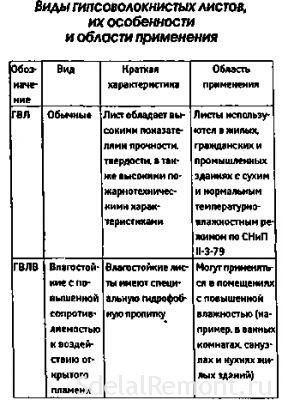

types GVL

There are two types of gypsum sheets, which can be used for alignment subfloor:

- normal. They can be used in premises with normal not only temperature, but humidity. For example, suitable room or bedroom.

- Waterproof. They are suitable for the device in rooms with high humidity, what could be the bathrooms, dishes, etc. They have a hydrophobic impregnation, due to which the capability of withstanding water only increases.

There is also the division of all the applied sheets with a low moisture formats, those marked with DIY. They have reduced dimensions 1200*1200*10 mm. As a result, production was reduced weight, created the best facilities in the installation process. Even one person is able to cope with the performance of the device quality and smooth floor. Throughout the volume of the sheet divided fluff wastepaper. They are further treated by impregnation, reduce the level of chalking. In addition there are water repellent, both from the back, and the front side.

Properties and quality

All quality GVL It is estimated from a set of characteristics. At their base it has a percentage of gypsum and cellulosic fibers. The first component is much larger and the number comes up 85%, everything else - cellulose.

density gypsum sheets remind keramsit indicators, that approximately half, than the red brick. The density will depend on the thickness of the material, device used to smooth floor. It will be increased by decreasing layer GOLS. When the thickness in 10-12 their density is mm 1200 kg per cubic centimeter, and in 14-19 mm - 1250 kg / cm3.

Density Compressive material indicates the ability to withstand external influences. When you compress it comes to 100 kg per cm2, and on a bend - 53 kg. In the first case, such parameters can withstand even the heel, which will not deform the surface.

Required tools

Gypsum fiber sheets are often used in the case, when subfloor It has no significant height differences. Typically, the figure is up to 5 mm. But there are other technologies, allowing to apply a material to perform smooth surface.  In any case, the need to stock up on everything you need tool, which include:

In any case, the need to stock up on everything you need tool, which include:

- Roulette for precise measurements in the room, including determining the size of sheets on the surface.

- Pencil - make notes and mark sheets, as well as on the walls in the room.

- Putty knife.

- Cutter - for full sheet cutting into pieces. If you use a quality tool, there will be no problems with damage to the material.

- Level.

It is important in this case pre-calculate the required number of sheets of GOLS, which will need to purchase to complete the entire scope of work.

preliminaries

Among these materials has the best quality, perlite. Grinding his thin, allowing it to distribute evenly over the surface. The density of it is very high. Due to the high cost of production, perlite, often mixed with sand in a ratio of 1 to 3. Cheaper material - concrete block. But even in this case it excellent performance and characteristics. He also serves as a sub-floor insulation.

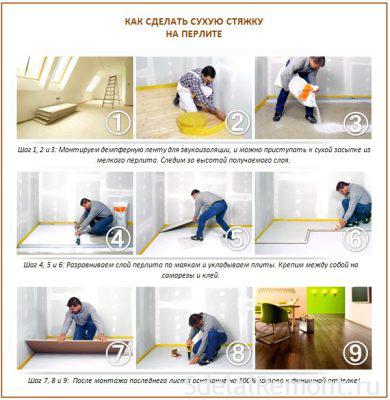

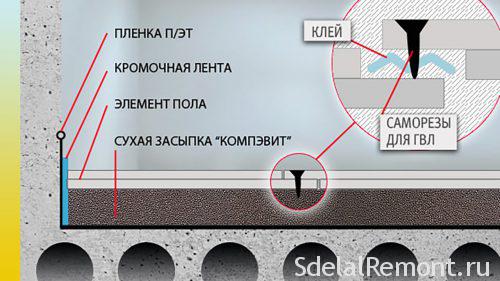

Before starting work, should be laid polyethylene film on the floor surface. It is usually put in two or three layers for better quality and reliability. In this way, performed vapor barrier, is able to protect the subsequent dry podsypku, and GVL sheets of moisture. This moisture can flow to the surface from under the floor.

from company Knauf offered their own material, called waterproofing Flehendiht.

installation of drywall

when performed training base for subsequent floor leveling , you can proceed to the next stage of installation. Originally performed backfilling selected the dry mixture to the surface over the entire area of the room. But it is more suitable for small areas of work. When we are talking about significant areas of premises, it is possible to perform breakdown on the area portions, which are fenced off by special rails. Anyway backfill material It shall be distributed evenly over the entire surface.

begining drywall installation - from the front door to the room. It comes from the fact, it is prohibited to walk on the surface of the filling. She may lose evenness. In this way, will appear recess, and as a result - uneven subfloor. Flooring flooring will not bring the desired result.

When laying a subsequent sheet of drywall beside the previous, joints edges should be smeared adhesive solution. And carried out between a compound of sheets, their quality mount. If you are not sure, that laid the drywall will remain in place and in operation process, then additional sheets are fastened to the base by means of screws with a double screw. Between this kind of fixture is necessary to maintain a distance of 30-40 cm. it is worth paying attention to, to the edges of the sheet of drywall screw it was located at a minimum distance 30 mm.

When all the sequential steps, you can be sure, that the surface has turned out flat. Now you can safely run laying laminate.

helpful hints

Align floor with plasterboard can be their own hands. But at the same time should pay attention to the subtleties of certain works, that will get the desired result.

- Sheets for the room to be included in the pre-quarters prior to installation. Sheets must adapt to the temperature conditions, and a humidity level, supported in the room. Spent time to start work - no less than 9 hours.

- Stacking of two layers of sheets is performed with shift, ie in a staggered manner. Joints should not coincide with each other. Step is usually 40 cm.

All these little things at first glance, would lead to the production of excellent final result. With a minimum investment of money and effort, you can get a base, Fit the horizontal level.