On completion of tiling walls, there is a very important issue, how to drill tile drill. And even more important is the, how to drill the tile on the wall. It should be noted, that quite often is first conducted itself tiling, and after make holes for switches, sockets and other accessories, like hangers or brackets for lockers.

Also, in some cases, specialists perform cutting tiles and holes in it in advance. But in each of the situations you need to know the technology of work, and most importantly, to choose the right tool.

Before, proceeding directly to the selection tool and the drilling process itself, one should note the complexity of the work. it is, that the tile is quite fragile, and therefore it can easily crack. That is why you need to carefully choose the right tool, and strictly follow the technical advice on work.

It is worth to highlight that the floor tiles is much stronger, read more such as drilling stoneware tiles.

Selecting a tool for drilling tiles

Accordingly, the first question, which should be paid much attention becomes, than drilling ceramic tiles. There are a few requirements, which should correspond to the working tool:

- First of all it should be able to control the speed of rotation of the drill.

- Another important factor is the control of pressing (pressure) on the surface.

In this way, you can note, that any tool with perforating elements will not work.

Very good option becomes screwdriver, at the same speed with a small speed. It is also important to a complete lack of vibration or jerky movement.

A second type of instrument, which can be used is a drill, with speed regulation.

As I mentioned earlier, the use of any tools with shock function is prohibited. ie. any drills or hammer drills should be strictly excluded from the working tool.

You can use a percussion instrument only for walls, respectively after, like tile was drilled.

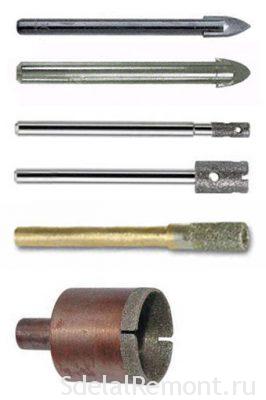

tile drill, its brand and purpose

The next question, how to drill tile drill. Here everything depends on several factors, in particular:

- What size must be a hole.

- When the drilling is carried out, before or after styling (also see more detail for laying tiles)

- Also choice in some proportion will depend on the workload.

Let's take a closer look, What drill to drill tile in different situations. In particular, If the tile is put, or to its packing, and also to make a small hole or a large, if necessary.

How to make holes in the already laid tile

First of all look at the most popular option, Tile drilling after laying. Answering the question of how the drill bit to drill the tile in the bathroom, It must first be determined from the size of the holes. detail, how to cut tile around obstacles.

The holes of small diameter

In the case of a small, which provides, for example, by dowels or brackets for shelves, a good option would be to use a drill with a spear tip. An important factor in this case becomes the density of the material, as compared to just drill should be several times higher, than the tiles.

the best, but at the same time the most expensive option of the product, It becomes a diamond drill. but note, that it is best to purchase for a large scope of work. In order to make a few holes, such purchase is impractical.

Home can buy inexpensive drill pobeditovye soldering. They will be quite enough. In particular, for the following brands fit:

- Pepper 7705

- Bosch CYL-9

- Bosch CYL-9

- Irwin

- Stayer

- Makita

- "Zubr"

This is the most high-quality and popular brands hastate drills. The average cost of a drill 150-200 rubles.

Large-diameter hole

And the second question, for the already laid tile becomes, What drill to drill for tile installation sockets. There is already faced with the task to make a big hole, and above the need to closely consider.

Luckily, everything is thought out for you, and can only follow the advice. Thus the answer to the question how a drill to drill the tile in this case is simple - a crown.

It represents a kind of tubular drill bit with diamond-tipped additional. A good option would be the purchase of a set of drills, to make holes of different diameters.

Although this acquisition is a perfect solution, but it should be noted, that this type of accessory rather expensive. While at the same time it helps to significantly save power, obtain the best result.

Using this type of drill, ultimately, You can perform a fairly large holes, up to 15 centimeters. Here are a few stop, and pay attention to a few rules, that must be followed when dealing with this type of equipment.

- First of all it is necessary to operate at minimum speed. This helps protect the tile from cracking, and prevents rapid wear of the cutting part of the drill.

- And the second rule becomes a need for continuous cooling of the drill, for which recommended to periodically omit it in water.

We also offer to the some of the most high-quality brands of diamond bits for tiles:

- Diamond for Hard Ceramics Bosch 2608580315

- Diamond for Hard Ceramics Bosch 2608580304

- Diamond for Hard Ceramics Bosch 2608580306

- Diamond for Hard Ceramics Bosch 2608580302

The data bits are represented by the same manufacturer, in particular, by Bosch. The cost of this varies from drill 1500 to 5000 rubles.

for the wrong tile drill

And the second one, when it is necessary to drill a hole in ceramic tile, It becomes preparation for laying. Here, the need to make holes typically occurs in two situations:

- Advance preparation of holes for communication systems, sockets, switches and fixing.

- Laying the tiles in the presence of the wall of the pipe and communication systems, that stick out. Provided, that the possibility of dismantling temporary absent.

There are several types of drills can also be seen, in the first case for large openings, Second - for small. but note, that the same tools are used for the second situation, as for the already laid tile, but for larger diameter drill uses a bit different.

In this case, without the possibility to buy expensive equipment, It finds its use of a special type of drill - "Ballerina".

To begin with we shall understand a little, what is a 'Ballerina'. By design, it is quite simple, and is somewhat reminiscent of a compass. The system also acts like. In the center of the alleged holes placed tip, and the cutter moves away to the required distance.

Cutter itself is made of special hard alloy, In some, more expensive models have the diamond deposition.

Using this kind of device has the advantage of good. It is the ability to adjust the diameter of the hole. In particular, it allows not to buy several models with different diameters, as it is necessary to do in the case of a crown.

You can also notice the shortcomings ineskolko:

- First of all difficulties at work, Since the drill must be kept strictly perpendicular to the tile, it is very difficult when working with large holes.

- Besides, After drilling needed further development and processing margins, because they do not always turn out perfectly smooth.

The rest of the, you can select a lot more benefits, such as durability, low cost, and most importantly, a good answer to a question than to drill holes in the tile.

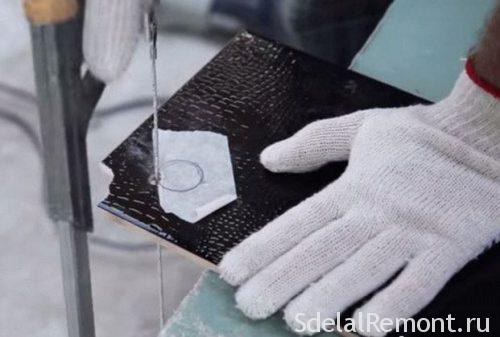

Talking a little bit about the tile preparation for such treatment, it should be noted, it must first be 30-40 minutes hold in water, prior to drilling. The work itself is carried out with a small turnover, and the tiles need to hold fast. Besides, in this work formed a lot of debris and dust, because it is desirable to use gloves, respirator and goggles.

ceramic tile drilling technology

And now, after analysis of the question of the choice of instrument, you can go directly to the problem, how to drill the tile in the bathroom. In particular, We analyze the technology of work.

Drill tile drill is not a difficult task, but quite tedious. It is important to observe a number of rules, for, not to damage the tile. In particular:

- Work is carried out strictly on a small cartridge rotation speed.

- On the tool when drilling can not press hard, better and does press to minimize, to prevent damage to the tiles.

- It is necessary to monitor the temperature of the drill, it should not be heated. Otherwise, under the influence of increased temperature can crack tiles. Therefore, it is necessary to periodically cooling with water.

Now, Having considered the basic rules, Let us examine the question, how to drill tile. We do this in a step by step guide.

It plays an important role directly tile, which is expected to drill. In particular, its surface. Most of the material used on the premises, glazed. On this basis the bit often slips and slides down.

To avoid this problem, it was initially a clear fix, for which the following activities are carried out:

- When working with a small hole, can be incised recess, in which will be drill. For this purpose, screw or file.

- For larger holes used as masking tape. Paste it on the surface, you completely protect yourself from this problem,.

- And the last option becomes the fulfillment of the mark, the correction pen. Thanks to him, the surface becomes rough, avoiding slipping drill.

After solving the problem with the possible soskalzovaniem drill, you can begin the process:

- Bit presses the end of the drill bit to the surface of the tile and start drilling.

- everything is done, as mentioned, at minimum speed.

- After that, It was drilled as a tile, It can be taken for further work normal drill or a hammer, to make a hole in the wall.

- Upon completion, it is desirable to polish the rough cut of the hole. To do this, you can take a subtle drill trimmed sandpaper.

In this process is complete. It does not matter what drill bit to drill tile, for large or small holes, technological features are the same in both cases. The only difference is the need to provide secure tiles, during drilling before laying.

Clearly following recommendations, you will be able to choose than to drill a hole in the tile, and also make it. In this way, it will help significantly to save on the services of a specialist, because on average one hole worth 150-200 rubles (not to mention the the cost of the packing). Also, for visual studies suggest videos, which is shown in detail, such as drilling in tile seam, how to make the holes and another at the site https://sdelalremont.ru