A good solution of comfort and warmth everything in the apartment and home in recent years was the installation of an infrared heat-insulated floor with their hands. This type of heating installation attracts simplicity and good performance. And in fact,, that self-install radiant floor will need a little knowledge and time, but it needs to know the number of the nuances of the work.

system Features

This type of floor heating(IK) It is a film in combination with a carboxylic paste, which heats the floor and the room with the help of infrared radiation. And this kind of quickly gained popularity, thanks to their advantages, among which:

- Easy installation.

- Possibility of arrangement of any coating under.

- Durability.

- Protection for human health.

- Fire safety.

And this is not se the benefits system. Among the drawbacks typically allocate only relatively high cost, and, little harm from radiation (in case of wrong selection).

Also, when buying should consider some of the nuances:

- Infrared film does not fit into the placement of furniture or decorative elements.

- Pre-planned film arrangement and wiring.

- also taken into account, that in the place to the temperature sensor must be free of drafts, and other factors, locally altering the temperature.

Selection of power floor heating

As with any electrical underfloor, infrared is necessary to select the desired power, that is, depending on the coverage area. And to make it quite simply as follows::

- It is necessary to calculate the required area before purchasing this type of floor. In particular, the calculation is subject to space, where there will be no furniture or will stand a small home furnishings.

- With an active area of 20 square meters of selected power system 220 Watts per meter.

- should take a less powerful system for large areas.

- Recommended trusted advisor, that will help you with the choice of the system.

Also, when you buy should pay some attention to wiring, and take into account the following factors in this:

- The wires for connecting the film thickness must be at least 1,5 millimeter, the best thing 2-2,5 mm.

- It is recommended to use stranded copper wire, considering, that the heating channels are also made of copper.

Self-installation of floor heating

Now it's time to consider, how to install a warm floor independently infrkrasny. And here it is necessary to distinguish two stages of works, in particular:

- Substrate preparation.

- Mounting films.

And let's look at each of them.

Preparing to install IR sex

The preparation is carried out only a few processes, and it held a total of, following the instructions below:

- Before laying the floor should be cleaned thoroughly. Completely dismantle Stroe coating, if necessary, carry out floor leveling (screed or self-leveling floor, if there is a deviation of more than 3 millimeters). About how to do this read our other materials.

- The next step is a niche for improvement thermostat. In particular, ranging from the installation site, using a punch or shtrobirueschego equipment must be sealed Stroebe to place the thermostat setting. And also perform an opening to install.

- It is very important to do it in the first place, to the completion of works to remove debris and dust.

- Next on the nearest point of wiring is necessary to hold the place of supply (do not forget to pre-disconnect system).

- Then, thermally insulating lining the floor covering. You can pick up a reflective material or not. The main factor here becomes the insulation thickness 3-5 millimeters. In this layer will continue to settle holes, for laying wires. Settling insulation sheets are bonded in the usual scotch. In the case of a decision to purchase the reflection sheets, Do not use the cover foil, as this poor quality material.

- Basically, the choice of thermal insulation depends on, that will lie on top of the infrared film. If the laminate, linoleum or carpet - should underlie penoterm or izolon, if the tiles - suitable technical cork sheets.

At this training is over, and you can proceed to the installation of the system.

Installation of the floor with their hands

Now we proceed to laying proper infrared film. That is performed in accordance with the following technologies::

- It starts laying at the far end of the wall, which will set the thermostat. Thus will significantly save wire consumption.

- Retreating from the walls 10-20 centimeters, in the case of heating elements (heaters, fireplaces), them indented meter.

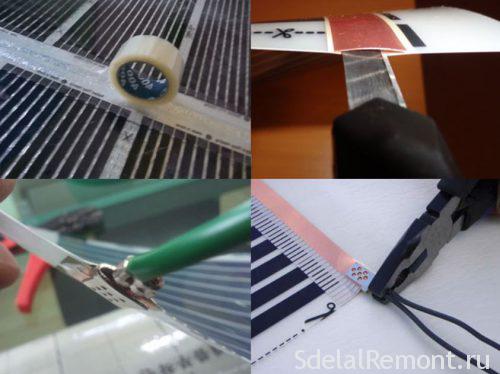

- The length of the strips of film can be adjusted, simply cutting it by special dividing strip, markup manufacturer, or between the individual heating strips. It is important to take into account, that can be cut only by the light areas, which run between the black stripes heaters.

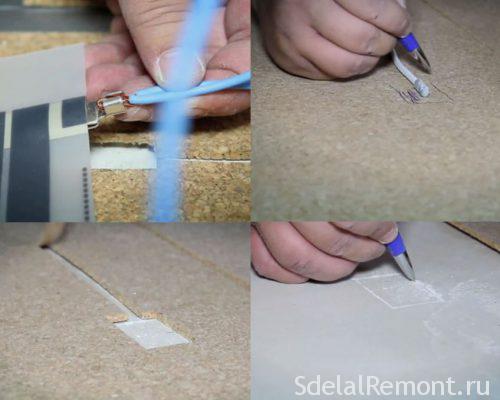

- Cropped side need to be isolated. For this purpose, a regular mounting tape. If the film is cut in the ground, specified by the manufacturer, It is isolated only collectors (copper strips on the sides). If the cut extends between the individual heating strips, the isolated edge across the entire width. film strips should not overlap or come to each other.

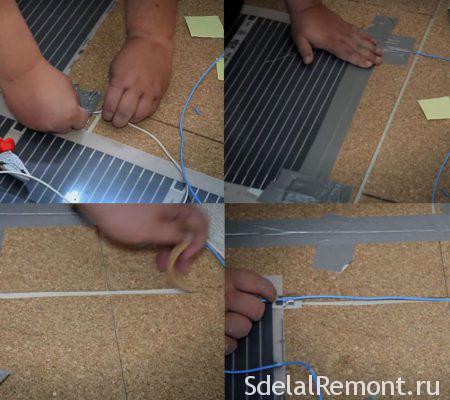

- Stacked film butt, after which the adhesive tape is fixed between a. Presently, place wire fasteners remain open.

- Directly laying itself is conducted down copper heaters.

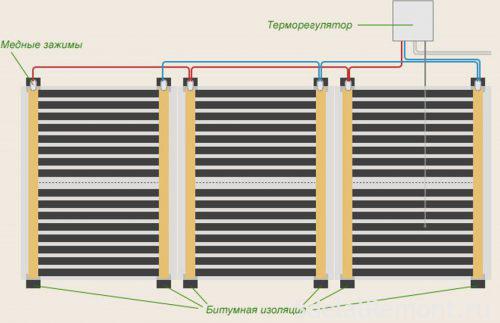

- Also worth noting, that the segments have an open copper areas, in places the cut, which also must be isolated, otherwise, the floor can be burned when leakage. For the isolation of bitumen film is well suited, which is easy to paste data plots.

- After that secure the film to the insulation by means of scotch. It is important while leaving open areas for connection.

- The next step is to install terminals for wires. they are connected to the bare areas on film. An important factor is the, the clips must be inserted between the band and the film, instead of clamping contact. This is because, that there is a great risk of damage to the film, respectively, breach of the functioning of the floor.

- After that, how inserted clips, time comes the wiring. Its better to be laid in a specially made Stroebe. Or you can get an external wiring. Preferable to use copper wire diameter 2 – 4 mm. Fasten the wire in the contact terminals, while they themselves set the clamps on copper collector strip.

- Strips infrared film is required to connect a strictly parallel circuit. ie. all the left sides of the film are interconnected with one conductor, rights of others. It is recommended to use two wires of different colors, that will not get confused. To consolidate remove insulation from the cable, and then twisting the end inserted into the hole on the clamp. the installation location of the infrared film warm floor should be insulated tape adhesive tape based on bitumen.

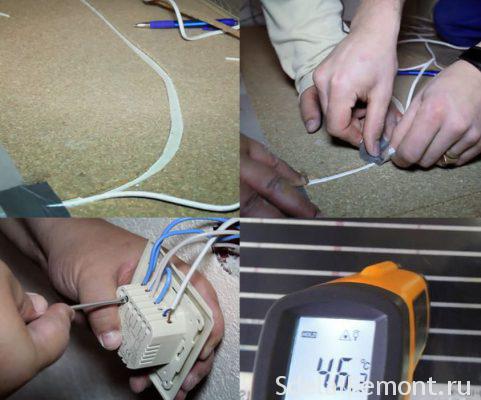

- Themselves wire cable across the floor to the wall, and then carried out under the skirting to a power source. For their laying need to make holes in the insulation for the drowning. Thus the wire laid in the holes, and fix with tape. In this manner, first conducting wire from film to film, and at the end of the wall.

- Now connect the temperature sensor and isolate it. To do this, the sensor is mounted under the film, its location approximately in the center of the second section. For the sensor itself also cut a hole in the insulation, if necessary, groove is in the basis. Also worth arrange and channels for wires, at every turn make a smooth bend, that the wire did not break down over time.

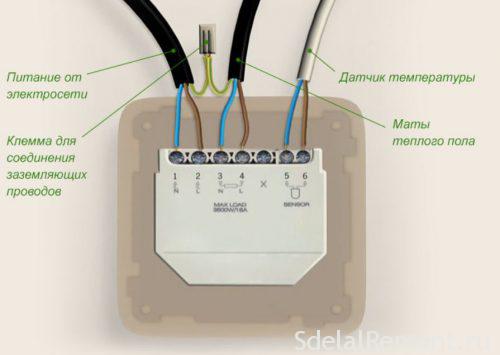

- connect the thermostat, its connection is performed in the same way, as with all other floor types. Namely, two supply wires are connected to the main contacts, from the temperature control is carried out to connect the two wires to contact the film itself underfloor. It is also worth provide for the installation circuit breakers on the short-circuit case. Ground in this case is connected to the terminal, but it is not connected to the contacts.

- turn it to the test system 30 degrees - is nowhere to be sparking and overheating in the joints.

- Tester measures the total resistance of the system. It must be a multiple of the resistance of the film itself (clarify instructions) divided by the footage of the film laid. If it is much more - it is necessary to double-check the connection is correct.

- Top bed should polyethylene film sheets for waterproofing. The edges of the sheets should overlap somewhere 20 cm. Glue them with adhesive tape. Now it is possible to stack the main floor covering.

In this installation process is completed, and the last stage becomes laying finishing flooring.

conclusion

So you see, that the connection and installation of infrared floor can easily do yourself, without the aid of professionals. This type of heating is gaining more and more popularity among consumers, so watch the video of the installation of the infrared floor with his hands firm Caleo and maybe you, too, like their technology and ease of installation.

The most complete video instructions on how to do the installation of infrared film floor heating, many examples and explanations of the process, strongly recommend to the overview.