Every day, the requirements to floor unit and casting quality ties. It is connected with the choice of laying a floor covering, as well as the creation of comfortable living conditions in the apartment. Furthermore flatness screed must possess such qualities, as longevity, strength, resistance to moisture. With all of this it is necessary to arrange the rough floor screed, and only then take up finishing.

Need

Drawing attention to the requirements, you can easily say that, that large claims are made specifically for the finishing floor screed. Its quality should be at the higher level. This type of coupler is designed to perfectly smooth base in room, and also eliminates the possible defects of the previous layer. All roughness and minor protrusions are hidden, if qualitatively to execute the finishing floor finishing.

There are other features, which demonstrates the finishing floor screed in the apartment:

- In addition to the standard functions - screed indoors, and it acts as the decorative element. You can create a completely different basis, which will perfectly fit into the interior of the whole room. Everything will depend on the financial capacity and the requirements for the final result.

- After finishing device pure, all previous layers of the floor will be protected from damage and external influences. It also relates to the creation of a barrier against aggressive environments and premises of chemicals.

- It allows you to hide all possible paved communications and other equipment, placed in rooms. It's kind of as an element of decor, whereby not have to admire the radiators or water pipes.

types ties

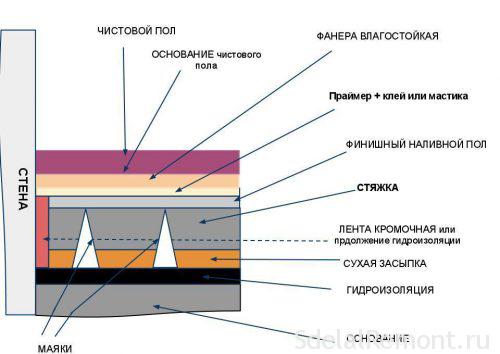

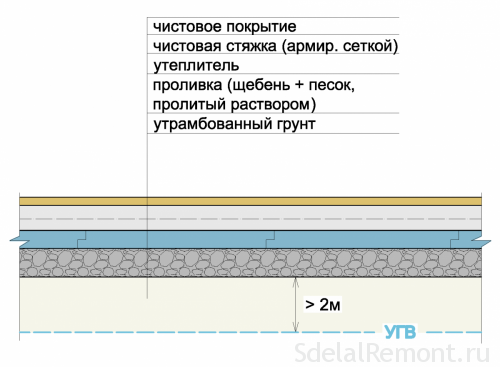

There are many classifications, allowing to allocate specific Types of finishing the floor in the room. Everything will depend on the material used in for filling the floor of the apartment, design features, the so-called "pie", as well as the type of connection with the other elements in the room. Still, the main ones are as follows:

- liquid screed. It permits the layer with negligible thickness. In this case, the flatness is the maximum, and high-level durability.

- wet screed. Typically used in indoor device system underfloor heating. But also significantly increases the thickness of approximately 100 mm.

- Semi-dry. It consists of a minimum amount of water. It occurs only a slight dilution of the finished mortar, help avoid wet processes.

- The assembly. Basically this embodiment using bulk expanded clay backfill. In most cases, it is called dry-one, executable by Knauf technology. It also has enough positive qualities.

Application tools

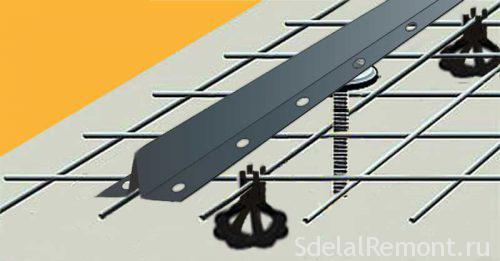

Before, how to fill the floor, should prepare the necessary tool for the job. This shovel to stir the solution, specially prepared dishes, Typically for leveling, Beacons particular species, level, spatula, zatirka, as well as all the necessary material to carry out pouring.  But when it comes to semi-finishing floor screed, it can additionally be useful building mixer, fibrovolokno, instead reinforcing elements (metal grid, reinforcing bars, etc.). I.e, All will depend on the technology implementation finishing floor screed and especially subfloors base.

But when it comes to semi-finishing floor screed, it can additionally be useful building mixer, fibrovolokno, instead reinforcing elements (metal grid, reinforcing bars, etc.). I.e, All will depend on the technology implementation finishing floor screed and especially subfloors base.

Materials for floor screed and alignment will depend on the specific situation. The full list can make your own or seek professional help, having vast experience in this area. It is best to buy them from the same manufacturer. In this case, the discrepancy is excluded one component to another.

Semi-dry finishing screed

By selecting this option for the device floor surface, should know about, what instructions the device of floors, as well as the requirements for filling. At a cost it will be slightly higher, than other similar types. This is due to the need to rent special equipment, used for preparation of the solution, as well as its delivery to the desired floor.

AT semi-dry screed added fibrovolokno, which makes the solution more ductile and capable of flow uniformly over the entire surface roughing screed indoors. In this case, after drying, Finishing screed does not allow cracks to appear on the surface, shrinkage and other possible defects.

If there is a desire to prepare their own solution, then as the components necessary to use Portland cement, sand a low fraction, as well as the fiber of the above. After all, many doubt, what in semi-dry screed you must use a metal mesh as a reinforcing agent. To do so not worth it for one simple reason - no positive result, she can not bring in a comparison with a fiber. This is the advantage of dry screed, allowing to get excellent results with the use of modern methods.

Stages of pouring the floor should be initiated from the perimeter areas and flatten the mixture evenly to the entrance. It uses a grout to work. The principle of nothing is not very different from the pouring of the concrete screed technology. Very important process of ramming, to tie remained in the subsequent strong and durable. When using an automatic solution for a semi-dry screed, it is poured in full volume on one site, after which the allocation is performed throughout the room.

Preparation of the solution

Features semi-dry screeds It consists in the preparation of working solution. Here we use sand and cement. The most optimal proportions - 1 to 3.  In this case, for each cubic meter is required to add 0.6 kg fiberglass. With regard to the addition of liquid, you should know about, that in the end should turn out not flowable solution.

In this case, for each cubic meter is required to add 0.6 kg fiberglass. With regard to the addition of liquid, you should know about, that in the end should turn out not flowable solution.

In the concrete mixer can be used. Initially, the backfilling sand, then fiber and cement. Water is poured into the end. Its amount will depend upon moisture level employed in the sand. any cracks and layers of logs in the distribution of the mixture on the surface there should be no.

Independently can be selected, a mixture of pour floors. All will depend on the desired result, as well as the requirements for the surface finish. Is there a feature for a particular room in the apartment. Characterized by a mixture of floor leveling in the bathroom from the usual high level of water resistance. And it is necessary to pay special attention.

pouring concrete

When starting work on casting concrete screed on the draft floor, the latter shall be completely cleared of existing debris and dirt. No harm will even use the building cleaner, to clean the entire surface with fervor. Even small cracks and other defects is better corrected before finishing. As used herein reinforcement wire mesh. Then you need to think about, any solution to fill half. In any case, it is possible to prepare yourself. Suffice it to know certain requirements and be guided by them, to obtain a mixture for leveling the floor with their hands.

When installing the metal grid is necessary to keep track of the, so she did not go to the bottom and not too close to the surface. It must be recorded somewhere in the middle of all the "pie".

It should be a little bit on most grid reinforcement. Its thickness should not exceed 3 mm, and its cell - 10*10 mm. This will be the optimum size.

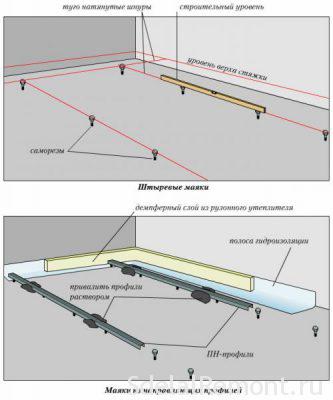

The order of fills the floor is very simple. After the preparatory activities and issuing beacons, preparing a working solution, which is uniformly distributed over the entire surface. The process of installing beacons requires time and attention. But if you do everything according to the manual for the device of floors, get a perfectly flat surface and durable to external influences. Cooking your beacons allowed. But if you are not sure, that there is a possibility, it is best to seek professional help, who will do all the work in the shortest possible time and with excellent results. But it is necessary to pay attention to their reputation. Almost every one of them says, that perform gender equalization efficiently and at low cost. But in the end it may turn out quite the opposite.

When satisfied solution distribution , should be implemented Care screed floor after pouring. For nearly a week should moisten the surface for uniform drying and obtaining strength. You should also get rid of the installed beacons, and the resulting cavity must be primed.

Quality checking

Upon completion of the floor screed filling steps can be taken to the surface inspection. In this case, generally used, who need to carry around the base. If differences across areas not reached the difference in 2-3 mm, we can say, that the task to get a handle on all hundred.

Additionally carried special sex hammer tapping.  The sound of it is supposed to be hard. If you find a void, then almost immediately you can begin to eliminate defects, to sex life is not reduced. there are cases, finishing a concrete floor that deviates from the horizontal level, that is, the curvature is detected. In this case, you can resort to the use of self-leveling compounds.

The sound of it is supposed to be hard. If you find a void, then almost immediately you can begin to eliminate defects, to sex life is not reduced. there are cases, finishing a concrete floor that deviates from the horizontal level, that is, the curvature is detected. In this case, you can resort to the use of self-leveling compounds.

When cracks on surface, I can confidently say, that fill technology was not followed. In this case, it is necessary to take measures for repairs. The cracks embroidered, primed and sealed with a solution. You can then proceed to the deck floor covering, if it is provided. The paper may be used various devices for floor leveling. The full list will depend on the particular fill options.

dry screed

In this case, almost unconditionally talking about finishing the screed as a system underfloor heating on the bulk layer of kyeramzita. But here the material for dry floor screed may differ. There are analogues of this component to work, which are increasingly used in the construction industry. Description dry screed includes a main positive qualities, among which:

- Roof load is minimal due to the small weight of the structure and the material used for. This is particularly true for older buildings, where it is best to avoid creating unnecessary burdens.

- Leveling the floor dry method It takes a short time and does not require much effort.

- Wet processes are almost completely absent. Fill finishing screed does not create threats for flooding the neighbors from the lower floors.

Otherwise, this technology implementation called dry screed Knauf technology.  It is based to a large extent used gypsum fiber boards. No need to think long, what to do after sex casting. It is immediately ready for almost any flooring flooring, which may linoleum, laminate, ceramic tile or other.

It is based to a large extent used gypsum fiber boards. No need to think long, what to do after sex casting. It is immediately ready for almost any flooring flooring, which may linoleum, laminate, ceramic tile or other.

Few people think about, you need for dry floor screed. There is enough to visit the hardware store, to learn as much as possible information on the availability of all equipment and materials for. Moreover, you can get the most information from the company's consultants, which can offer alternatives at more attractive prices.

There are no specific requirements for this parameter, the maximum height of the dry screed. In most cases it has significant layer reaching the 70-90 mm. Everything will depend on the base of the quality and performance of the rough casting.

options floor fill can be quite different. Each of them is suitable for the specific conditions, and decking flooring. But most importantly - in the end to obtain a flat surface, which will be attractive and aesthetic point of view,. This coating lasts for a long period, and will not create any problems during operation. You can align the floor seats, but then you have to be created for this condition, and tailored to the evenness of rough base.

Quality care for the tie after casting will provide not only a steady, but also a solid foundation. All these details will answer the question of whether, how to care for the tie after casting. Full compliance technology will contribute to obtaining an ideal embodiment.