Today, the system of underfloor heating is very popular. This is due to a large number of positive qualities, and the possibility of any flooring embodiment of floor covering. In addition, you can choose absolutely any alternative heating system, depending on the need and the room itself. But it is worth noting, that the installation of underfloor heating components should pay special attention to insulation layer, so that heat is not wasted just like that. There will be excellent options substrate under floor heating. The main thing to know, choose what kind.

Requirements to the substrate

Many questions immediately arise. Foil in the construction of a warm floor. Works or not? Needed or not needed? How do different types of screeds affect the performance of a warm floor?. Infrared radiation or heat conduction? The rate of reaction of a warm floor to a change in the temperature of the coolant.

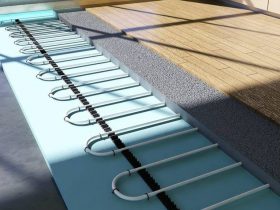

The basic substrate material for the under floor heating - polypropylene, polyethylene foam. They are covered by a Mylar film, having a metallized layer. The latter serves for even heat distribution. All the other components do not allow heat to escape to the downstream floors, and completely transferred into the room, Warm air from the subfloor.

The porous substrate under warm floor It has a very high allowable temperature, that reach 90 degrees. This allows for stacking heating elements immediately on film. All this points to the excellent quality of warmth and waterproofing material. Also isolated and other qualities, which has the substrate - is soundproofing and a high degree of reflection.

On each substrate member under fill There is a special floor markings, reminiscent of the grid. This promotes fast and qualitative distribution of the heating cable of the electric floor heating surface, depending on the step, which is selected.

The substrate can save the order 80-90% thermal radiation. In this case, all energy costs are reduced to a minimum limit.

appointment

The substrate is placed between the concrete surface in the room, and heating system. The main purpose of the material - to prevent heat loss, which comes from the heating elements underfloor heating. Otherwise, the heat will be wasted, showing no effect. So it will only warm the ceiling to the lower floor.  If the substrate is correct, the sub-floor heating is not only uniform, but also twice as fast.

If the substrate is correct, the sub-floor heating is not only uniform, but also twice as fast.

Another purpose of this material underfloor heating system - barrier. He does not let the cold from the lower floors, moisture, as well as a couple. This is especially true for the first floor above the basement. Since the substrate has excellent sound insulation properties, in apartment buildings do not have to listen to the cries and noise from neighbors. and other materials may be used for the substrate:

- Bung.

- Fibreboard.

- The foamed polymer.

- Penofol.

- Folgizirovanny material.

- extruded polystyrene.

But even this can not be called an exclusive option. Technology does not stand still and is constantly being improved materials, which can be selected as the substrate under electric floor heating. Selection of specific material will depend on the flatness of the base, Where were laying, as well as on the type of floor covering in decoration finish.

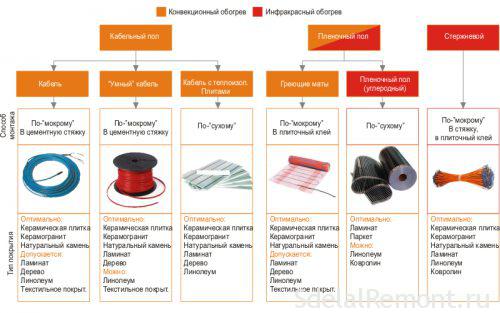

The substrate for cable sexes

The greatest efforts to realize characteristic of Cable floor heating. After all, here necessarily produced grouting screed. Prior to installation should be carried out a number of actions, which include:

- If the need arises, aligned grounds, which will be laid floor heating system.

For this rough screed is performed by all the rules and requirements.

For this rough screed is performed by all the rules and requirements. - Apparatus insulation layer, where it performed substrate selection.

- Performing concrete screed on insulation, which will serve as the basis for floor heating.

After all these activities you can begin to implement a heating system. By the laid mounting tape substrate is attached with screws. It is in the tape and fixed the heating cable heating systems. When the cable is placed on the prepared substrate, Perform a full electrical connection of all sensors and cables, can underpour concrete screed.

Particular attention is given to the substrate. In this embodiment, should give preference to aluminum foil. Its main task - to efficiently and evenly distribute incoming heat from the heating elements around the base floor.  There are two main reasons for this:

There are two main reasons for this:

- Create the same level over the entire surface temperature.

- To avoid local overheating of the heating element. All excess heat must be removed at least the heated portion.

Using Heated floor substrate under extends the lifespan of the entire system. The heating cable can last for much longer. He is constantly in operation, warming up the entire volume. Many positive qualities at first glance invisible from the use of substrates for floor heating.

It is worth noting, that the duration of the cooling subfloor will depend upon the area of its heating. Additionally elevated temperature provides the use of a substrate and, laid at all the components of the heating system in the room. It is important to make it laying in the installation process. small price, but there is a very high quality and necessary.

Radiant floors

There can no longer be regarded as a classic system embodiment. Despite the use of similar components of the substrate under floor heating, it has a slightly different purpose. After all, infrared film, and heating cable have different roles in the heat sources. The cable acts directly on the floor, from which the air is warm the room. Infrared film increases the temperature conditions selected floor covering, and environment objects, which can be furnished, walls, etc.. And from these elements begins to warm the air in the room.

On the subfloor made available waterproofing layer flooring, over which - reflecting heat insulating material. Last is the substrate under floor heating system. We can only produce flooring infrared film. Film sheets at certain locations interconnected, and then carried out their electrical connection.

for the substrate Infrared floor heating characterized by a very important feature - it can not be foiled. The aluminum foil may be used as the reflective element. It is fully compatible with the requirements of safe operation of heating systems. If any damage to individual parts of the heating elements, circuiting can occur on the substrate laid.

Substrate under infrared radiant floor has two main functions:

- thermal insulation.

- Reflection of infrared radiation, which is sent to the floor, but not in the room.

Low cost substrate allows it to acquire and use everywhere without fail. In addition, the savings of the order is going on here 30% the incoming heat. more precisely, reduced losses in the course of work Infrared floor heating.

The basic material for the substrate in this case - polymers or foamed polystyrene. Reflective material acts as a metallized polyester. It can be purchased in the same place, where for the implementation presented different systems of floor heating.

At first sight, this requirement is not necessary when apparatus infrared underfloor. But the effectiveness of the system, as well as the safety of heating in the room increases significantly. Even 30% reduce heat loss will be a noticeable and significant for any system. It is very important in the process of stacking technology to comply fully, and follow it from the beginning to the end.

The substrate depending on the final coating

The most popular floor coverings in warm floor a laminate. It is distinguished by the high cost of not, as well as the ease of flooring. In this case, you should think about, to get support, necessary to separate the coating from the floor heating system. Otherwise, there will be more chances, that free sites between the heating elements and the laminate will play. During the walk it will cause the appearance of taps and a particular sound.

The thickness of the substrate is typically under the laminate 2-5 mm. There are also specialized material for flooring, having a high level of thermal conductivity. pad It allows us to solve a number of problems:

- additional insulation.

- Shock between the coating and the substrate.

- alignment drops. To do this, acquire a soft surface. After all, laminate flooring requires a very smooth base.

- Preventing damage to the laminate elements.

- Prevent the emergence of a squeak.

Many manufacturers recommend using a substrate roll polyethylene. In addition, it can be combined with concrete solutions, cement. It is able to withstand a variety of chemical exposure, and microbial influences, causing the appearance of mold and mildew.

Another option for the substrate - a stopper, which is implemented in rolls or plates. It is executed from the pressed cork crumbs. Preference should be given to it rolls due to waste reduction during mounting just "pie". During operation, the plug will not deform and does not shrink. That's all, and tell, which under the laminate substrate under floor heating choose.

Another embodiment of the floor covering - linoleum. Here, Conversely substrate under Heated floor should be solid. Otherwise, from heavy furniture or a fixed distance may form indentations in the ground floor. As an excellent option - chipboard.

often used ceramic tile. Without underfloor heating it tends to stay cool even in hot weather. For electrical floor heating in such case, the substrate is best applied coating metallized Mylar. This will allow to warm the tile with maximum efficiency. Important in this case - to use a material of uniform thickness.

Features stacking

Installation of all components underfloor heating is essential. Its quality will depend on the efficiency of the heating system during operation. Particular attention should be paid is the substrate, which are subject to specific rules when laying.

- Upon acquisition of the polymer substrate of the metallized film, spread it should be reflective side up.

The material will have the following characteristics: environmental friendliness, elasticity, flexibility, subtlety. Almost no influence on the distance between the ceiling and the floor, this substrate will not.

The material will have the following characteristics: environmental friendliness, elasticity, flexibility, subtlety. Almost no influence on the distance between the ceiling and the floor, this substrate will not. - The substrate may be made from magnesite plate or fiberboard. It should be laid on the screed, which was covered with aluminum foil.

- Sutures sheets glued tape or adhesive tape. This action is performed without fail. At all, the material must be distributed over the entire surface of the floor in the room sploshnyakom.

All these requirements and the choice of a specific embodiment of the substrate for electrical floor heating system device should be observed, if desired, to obtain high quality.