Cable electric floor heating device requires mandatory concrete screed under Heated floor, which performs a specific list of functions. But first should produce surface leveling, the heating elements are well formed. During screed on their own should pay attention to the exact observance of technology. Otherwise efficiency warm air in the room will be minimized. It is important to understand not only in the design of ties and "pie" warm floor, but also to clarify all the details of, associated with the working solution.

Typically, the solution or not?

Often when using a conventional cement-sand mortar on top of heating elements underfloor heating one question arises - for some reason began to appear cracks? Here secrete several very good reasons, sposobstvuyuschyh this defect.

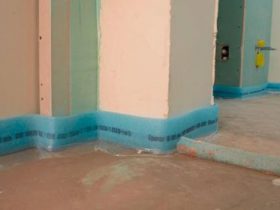

- The absence of damping tape along the walls of the room perimeter. During shrinkage solution, cracks are beginning to appear.

- After pouring the solution of a certain time gaining strength and dry. It should maintain a certain level of temperature in the room. Not a small value to play and humidity.

- Use of the grout too.

- Acquired alignment layer is too different from the optimal index height.

- The need to create expansion joints in areas with a large area.

- Drying took place by means of various heating systems, not independently.

- Not observed proportions in the preparation of the solution.

- Pouring the solution by stages. To achieve the desired result, The surface should be filled with the solution at one point, without distractions.

Terms of expansion joints

All proportions solution preparation must be precisely followed. This says it all, even on the packaging out of the mixture. In addition, experts recommend to use ready-made dry mix, in which only need to add a certain amount of water. With them a lot of trouble by pouring warm floor will remain on the sidelines. mixtures It can be purchased not only for finishing the floor heating system, but rough alignment beneath the heating elements. Everything will depend on the specific characteristics and the cost of production, to prompt, What screed floor heating is the most optimal and quality.

screed function

Concrete screed under floor heating to perform certain functions list, foremost among which are the following:

- leveling the surface, and the possible elimination of defects. Any base height differences will be eliminated, and thus the load is distributed evenly. Leveling layer protrudes most draft of a warm floor.

- It creates a protective layer for underfloor heating elements. They are not afraid of external mechanical influences.

- thermal insulation. I.e, heat preservation and passing it into the base of the heating elements.

- Creating a smooth and even surface for subsequent flooring selected option floor covering.

- Uniform transfer of heat from the underfloor heating system to warm the inside of the room air.

At independent performance concrete pouring underfloor heating should be remembered, inside to avoid air pockets. It will not allow the base to receive the same level of temperature during operation of the system. Efficiency of electric warming is not so, as the need.

Preparatory work

Before the beginning mounting heating elements warm floor, should perform consistently some very important actions:

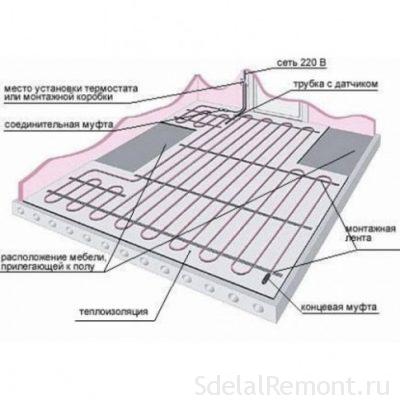

- fixing a position, where the thermostat is located. It is attached as a normal switch. The optimal distance from the floor - 30 cm. The following does not make sense to make its installation. Besides, that the drill holes in the wall for thermostat, it is done by another and a hole perpendicular to the ground floor, which will fit the power cable and other wires in the corrugation.

- Preparing subfloors. Remove all debris and dust, made thorough alignment surface. No pits and spikes should not be. In implementing the alignment, Ties thickness under floor heating is not less than electrical 30 mm. Otherwise the coupler begin to crack. Prior to distribution of the surface of the solution applied to the primer layer. In addition, areas are marked, where the furniture will be placed, and also refers to the indentation of the walls of the heating elements, which should not be less than 50 mm.

- layer insulation. It allows to reduce heat loss by about 30%. Insulation laying can be performed not only vertically, but also horizontally. Vertical insulation tape used damper, as well as polystyrene sheets, which is the width 15-20 cm. Reduced heat loss through exterior walls in the room. As for the horizontal distribution, here it is placed on a prepared concrete base. The thickness of the sheet is usually not less than 20 mm.

If there are areas with high levels of humidity, further arranged waterproofing layer.

Pre screed

Before the installation of the heating elements warm the floor should be made fill roughing screed. Usually it takes a cement-sand screed. This layer will prevent overheating of the heating cable. Moreover, the base will be much more durable for the subsequent creation of the whole "pie" warm floor. If it is impossible to create a provisional screed, over the insulation layer is placed a metal mesh, and to which is attached a heating element underfloor.  During the subsequent pouring screed is obtained a strong and uniform.

During the subsequent pouring screed is obtained a strong and uniform.

As soon as the cement-sand screed electric underfloor pick up the necessary strength, you can cover it with foil insulation, which acts as a foil assembly. She covered all the subfloor, concrete surface. It should be remembered that, that styling should be done with the stock. Edges and joints must be glued together with adhesive tape on the basis of foil. These actions are carried out with a view, that in the process of installation of the heating cable insulation is not swirled.

Foil shield is created from one main goal - a uniform distribution of heat during the operation of the electric floor under screed.

To subfloor heating cable is properly secured, often use the mounting tape. She puts on a surface in increments of 50 cm.  In the subsequent final fixation is carried out by means of screws or nails conventional.

In the subsequent final fixation is carried out by means of screws or nails conventional.

The cable must be properly fixed to the mounting tape. For this purpose special brackets apply, which are arranged at the same distance apart. Typically this distance is in the order 25 mm. Staples also allow you to select the required step of laying the heating element and to keep it in the process mounting.

"Cake" and the thickness of the screed

As standard, the underfloor heating system is arranged on top of the old concrete base. It is enough to lay the heat insulator, which can be penofol. This material was further performs a function and soundproofing.  After that, the heating cable is arranged on the surface. In the end - is performed pouring concrete screed. In the end, it all turns out "pie" of warm electric sex.

After that, the heating cable is arranged on the surface. In the end - is performed pouring concrete screed. In the end, it all turns out "pie" of warm electric sex.

Since the laying of the whole structure is performed at a relatively mild base, about the extra strength to say will not work. This points to the need to implement the holes on each square meter of used space heat insulator. Further, it should keep a distance of 10-15 cm along the walls in the room, the upper coupler rested on the lower base. Without it, nothing is impossible to do in those areas, which have a small area.

Bit is worth looking at the most screed. The usual thickness thereof is 30-50 mm. This ensures uniform heating of the subfloor over the entire surface. Will not face in this case areas (bands) warm and hot air. In exceptional cases, you can make a proper screed underfloor heating to 30 mm. But in this case should consider adding a solution further plasticizer in the required quantity. every 100 kg finished mixture will require about 1 l additives.

Laying of heating elements

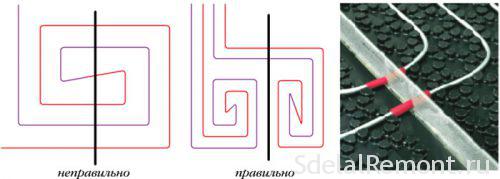

When the hands have a plan for laying the heating elements, you can start all activities. Particular attention should be paid to step styling. should clarify its resistance before the start of the unwinding of the cable. These data are written in the warranty card. It is worth noting, they must fully comply with the data on the label. Allowed difference indicators, but not more than 10 percent.

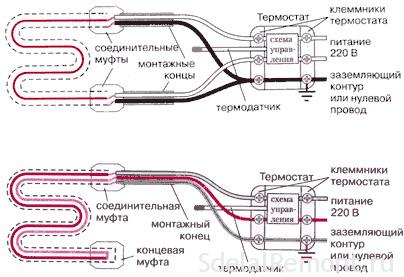

The cold end of the heating cable should be placed in the corrugation, then set made Stroebe. Start the cable must be attached to the mounting tape on the basis of sex. It is from this site and will be given the start of the cable laying. In the subsequent coupling must be fully covered concrete screed.

All lines of the heating cable must not connect and intersect with each other. Throughout the entire floor area must be maintained stacking step, which was previously selected. In those areas, where it is necessary to produce bend cable, its radius should be more 50 mm. To set the thermostat must be mounted two subfloor heating cable.

The temperature sensor and temperature controller

Thereafter carried temperature sensor installation. It is placed in a corrugated tube, producing plant together with the feed end of the heating cable. To the tube with the thermostat did not get the solution in the process of filling, performed a special plug. In this case, no problems with the replacement of the sensor during operation and it fails.

Stacking sensor is performed based on the floor so, so as not to cross the line of the heating cable. The best option fixing - in the middle of the cable lines, directly on the mounting tape.

installation thermostat It can be performed only in the case, when the junction box three main cable conducted:

- The wire of the temperature sensor.

- power cord, having a voltage 220 AT.

- Conductor heating cables.

If the room has an elevated level of humidity, then it is prohibited to perform the installation thermostat. This is contrary to all safety requirements.

When all the above steps have been completed, you might think about the preparation of the solution and filling concrete screed, having its own characteristics and mounting subtleties.

Possible solution formulations

It is difficult to point out, exactly what the composition of the solution must be at installation electric underfloor. Everything will depend on the support floor construction. So, concrete base load capacity in 230-250 kg per square meter of floor space. Stove of reinforced concrete able to withstand 1.3 tons. If we take into account the standard screed thickness, it creates a load of up to 180 kilograms per square meter.

The compositions may be of the form:

- concrete mix.

- The cement-sand mortar.

- The semi-dry composition.

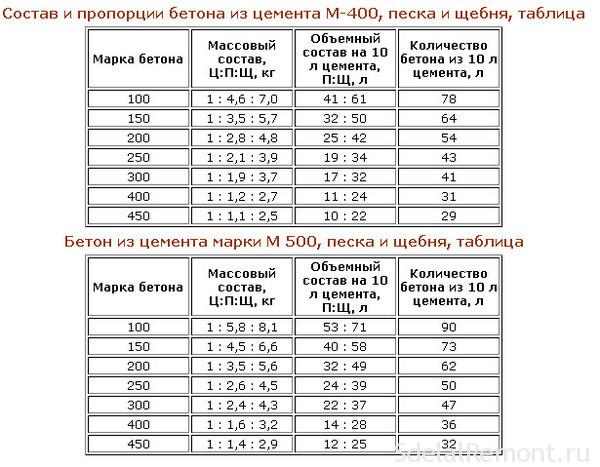

Preparation of the solution should be carried out with the following proportions:

Cement Grade alignment layer is not taken below M400. Here you can take a proportion of sand and cement, as 3 to 1. Moreover, sand must be fine fraction. Instead reinforcement or as an additional reinforcement protrudes microfiber, even having the best qualities and characteristics. Adding plasticisers to protect concrete mortar from exposure to elevated temperatures.

The mixed together all the possible components of the dry for five minutes. The plasticizer is mixed separately with water. Each bag of cement used requires about 5-6 liters of water. Additives in this case need to order 200 gram. In the future, only need to add all the dry ingredients into the water.

concrete solution, which is filled with the heating elements, has several other components and proportions: on 2 of the need to add sand 3.8 rubble. It all gets mixed with one part cement, grade M300.

Advantages premixed

Not to spend time on the preparation of the solution, you can buy ready-made dry mixes. They have a number of positive qualities, among which stands out:

- Lack of compliance necessary proportions of all components.

- On the packaging displays the detailed instruction for the preparation of the mixture and subsequent pouring.

- Weight ready mix somewhat lower self solution preparation.

This reduces transportation costs, as well as the carrying out of installation works.

This reduces transportation costs, as well as the carrying out of installation works. - Allows users to choose the most optimal composition of premixed. They may be suitable for any room, where to arrange a warm floor, as well as for any kind of flooring. There are no restrictions here does not exist.

- Dry mix less by weight, which reduces the pressure on the slab.

- The thickness of the screed It can be carried out and a thin layer of 5 to 30 mm.

- At independent performance of ties on Heated electric field it is best to use ready-made dry mix, allow to save not only time,, but also to some extent, and means.

Fill screed floor heating systems

Before mixing the solution and its distribution over the entire surface of the floor in the room, make sure, that warm floor is fully functional. It includes a certain period of time. The embedded guarantee photograph or sketch placing all the elements of the electric floor heating.

The optimal solution is prepared from specially designed mixtures. There should be no questions about, what to do to tie underfloor heating. In some cases it is possible to prepare a solution on their own, clearly proportioning. Pour the screed under floor heating should be evenly and accurately. The cable insulation must not be damaged. The most important thing, that there was no air pockets, reducing the efficiency of underfloor heating.

The thickness of the screed in such a case should be within 30-50 mm. Complete drying of the solution is 4 of the week. During this time, you can not operate the underfloor heating system, not to experience negative symptoms. Once the screed has hardened, you can begin to cut the protruding portion of the layer of insulation and damping tape. In the end - produced flooring option chosen floor covering.