At first glance it may seem, that the implementation of the installation of any version of warm electric sex takes time and requires significant knowledge. But if you look at the technology and all the steps, the laying of the heating elements can even a beginner in the industry. To do this, and there are specific instructions for installing floor heating, which should be guided not only by the choice of the components of the heating system, but also carrying out installation work.

Substrate preparation

To begin with you should pay attention to the base, which will be carried out laying electric floor. If possible, the old coating is removed together with the concrete slab coupler to.  This in turn will increase the distance between the ceiling and the floor in the room. All trash should be formed to make. Next underpour roughing screed, necessary to impart horizontal surface Rovnosti. The thickness of the solution up to 3 to 5 cm.

This in turn will increase the distance between the ceiling and the floor in the room. All trash should be formed to make. Next underpour roughing screed, necessary to impart horizontal surface Rovnosti. The thickness of the solution up to 3 to 5 cm.

When special subfloor no defects, you can not spend time on the draft of the screed, and proceed to the next steps. But still have to perform a screed for leveling height differences, potholes or other defects. In this case, you need to fill in screed with a layer thickness of 30 to 70 mm. By the next step can begin only after the complete drying of the alignment layer.

charting

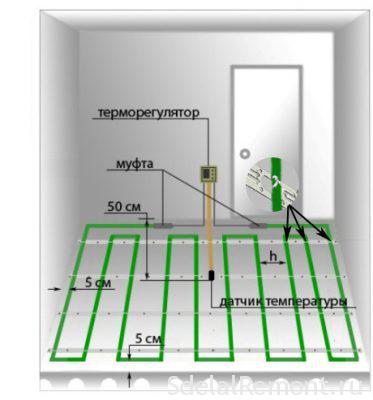

Until the moment of the direct distribution of heating elements on the floor surface in the room it is best to sketch your own scheme, which mark areas with furniture, selected stacking step and other aspects, which will play a significant value. This scheme is useful in the future when the deck flooring, not to damage the heating elements.

In preparing the plan should pay attention to some points, which will provide high quality results:

- Offset from the walls of the heating elements must be at least 100-150 mm.

- Rectilinear distribution of the heating elements is not compulsory. In every situation, even heating mats (sections) can be cut. the main thing, that was not damaged heating cable. These actions are carried out for the purpose of rational use of the heating system, reduce power costs, and concentrate the main heating subfloor in the right places.

- In the presence of bulky furniture in the room, built-in furniture, and heavy appliances, which are not scheduled to make their premises, should not be done laying the heating elements. Significantly reduce the heat, Consequently, warmed warm air will go back. This will result in overheating of the system at a single site and will lead Repair of floor heating.

The display step in Scheme laying electric floor heating is calculated by the following formula:

h = (S*100)/L

S - footprint heating elements.

L - length of the cable or the heating mat.

Minimum step for stacking the heating section is 80 mm. But it should not exceed 200 mm.

calculation of components

Calculate the required amount of the heating element based on the cost of the, which uses a heating system in the room. In the case of the main heat source of the heater power required 160-180 W per m2. If, however, an additional heating system, working together with radiators or other sources, it will be enough not to choose more power 140 W / m2. In the latter case, all will depend on, as the insulated space and the availability of sources of heat absorption (window, doors).

Initially determined base area, which will be heated. Here, as mentioned earlier, It will not be included the total area, Area furniture and other stationary items. It was obtained and the area will be useful, which should produce a laying of heating elements. The result will only determine the total length of the heating cable or other underfloor heating element, determine its total capacity. Each meter power heating cable is generally from 16 to 21 W. It should be specified at time of purchase.

You can give a simple example:

In a room with an area of 15 m2 you want to create the heater with a capacity of 100 W per square meter. So we get the total power, that will be needed - 1.5 kW. If you choose a cable with a capacity of 20 W per meter of cable, you will have to purchase 75 meters of the heating element. There should not be any of the compounds at selected sites, since resistance to change.

The same principle of selection characteristic and termomatu. But other than that additionally purchased mounting tape. It will not only qualitatively, but also easier to implement mount the heating elements to the base (concrete screed).

thermal insulation

Warm floor It must transmit heat only to the base floor in the room.  That this was the case and there was no heat loss in the downstream space, should perform quality installation a thermal insulation layer. This will allow to maximize the efficiency of the heating system, as well as reduce energy costs.

That this was the case and there was no heat loss in the downstream space, should perform quality installation a thermal insulation layer. This will allow to maximize the efficiency of the heating system, as well as reduce energy costs.

The most optimal option of insulation - penofol, presented in the form of rolls, having a foil covering. Attach it to the bottom is very easy due to the available self-adhesive layer. Bonding is carried joint to joint. That there were no sections with gaps, all joints are glued with tape on the basis of the foil.

Insulation layer should protrude somewhat on the walls. This will improve the insulating quality of the entire premises.  Alternatives heater only shorten the distance from floor to ceiling. In such a case it is possible to acquire polystyrene or polypropylene.

Alternatives heater only shorten the distance from floor to ceiling. In such a case it is possible to acquire polystyrene or polypropylene.

From the top of a heater mounted on the wall damper tape. It is created to compensate for thermal expansion concrete screed, as well as a floor covering in the heating process. To avoid direct contact of the heating element and the insulation layer, stacked metal mesh, serves as both the reinforcement layer. For it is possible to carry out fixing cable or heating mat.

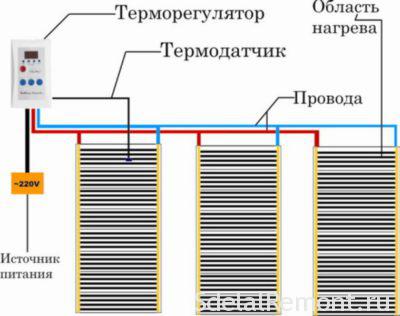

Installation of sensors and verification

Manage the system much easier, if there are appropriate sensors and instrumentation. The underfloor heating system this role is fulfilled by the thermostat and temperature sensor. All this allows you to set a certain indoor temperature depending on needs, as well as the time on and off the system.

Installing sensors made in the wall, near the outlet at a distance of at least 30 cm from the subfloor. But the temperature sensor is mounted in the floor. For this purpose, from the place of the thermostat is made perpendicular to the base in the wall Grooves, which falls on the floor and a few. It is placed initially corrugated tube, a temperature sensor which is placed. It is worth noting, that the sensor ripple must not overlap with the heating elements, and located between their turns. That did not get in the corrugation solution, all openings are sealed with sealant.

Before the installation of the heating cable measured resistance, which must comply with passport data. It allowed only a slight deviation is not more than 10%. Here a great help deliver Multimeter. If all matches, you can proceed to the distribution of the heating elements, according to the previously created schema.

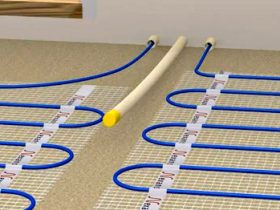

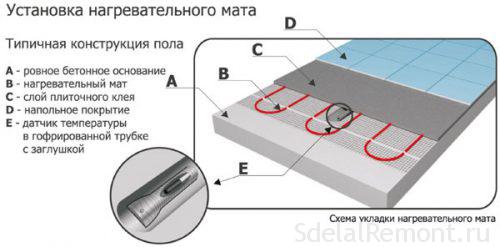

Fixing the heating mat and cable

When all the above steps have been completed and the surface is completely ready, You can begin to correct laying floors, or rather of the heating element. mounting tape perfectly suited for cable, to which each element is mounted and a floor construction.  If there is reinforcing mesh, the cable is attached to it by means of special clamps made of plastic. This is done very simply and quickly. the main thing, to order laying underfloor heating has been observed. The same actions are carried out and laying the heating mat. But this has its own rules and requirements:

If there is reinforcing mesh, the cable is attached to it by means of special clamps made of plastic. This is done very simply and quickly. the main thing, to order laying underfloor heating has been observed. The same actions are carried out and laying the heating mat. But this has its own rules and requirements:

- It is necessary to trust the recommendations of the manufacturer, to choose the option, which is required for a particular room.

- In the process of laying, as well as cutting should carefully monitor the condition of the heating cable. It must not be damaged.

- If the room temperature is less than, than -5 degrees, it is better to postpone the installation and laying floors.

- Connecting to the network mats are best left to professionals (electrician).

- thermoregulator It allows you to automatically disable the heating mats on the network. Without it you can not do.

- The mats should not be stretched under stress. All these external influences will lead to damage.

- Creating a grounding cable.

It is necessary to pay attention to the distance between the coils. It must be maintained identical to the entire area of the base floor in the room. From the Executive requires only properly decomposed heating elements and further connect their thermostat and other components.

All parameters of the cable resistance, as well as the correctness of connections should be checked after installation.

screed

proportions solution preparation very important. Without strict observance can not obtain the desired result. If you do not want to prepare their own material for tie, you can buy ready-made option in the store - dry mixes, containing all the necessary components.

With self-kneading components should be selected based on the following proportions:

- 1 part cement.

- 4 parts sand.

- 5 rubble.

- 5 of the water (water should be carefully, since it is very well distributed liquid solution between the heating elements, but quickly crack and fail in service).

- 01 of the plasticizer, imparting flexibility and strength solution.

such components, as perlite or expanded clay in general should be away from the solution for screed floor heating. They not only violate the heat, but also can lead to overheating of floor heating elements at a single site.

tie layer typically underfloor 30-50 mm. It is within these limits, and should work, to obtain the best efficiency of the heating system. Complete drying of the solution is performed within 28 days. In can not include Heated floor and run it in operation during this time.

Concrete screed is used only for heating cable. The heating mat does not require such serious external load. Enough for him instead of tile adhesive tie layer, and which dries much faster. You can immediately produce ceramic tiles.

Infrared Heating Features

For Infrared floor heating special attention should be paid to the preparation of the base, rather its qualitative alignment. It allowed only a slight deviation from the horizontal line (about 1 mm 2 square meter).

When an installation of floor heating, we can not forget about the flooring termopodlozhki, which can be foamed polyethylene, a layer thickness in 3-4 mm. Sure on the one hand it must have a coating of foil.

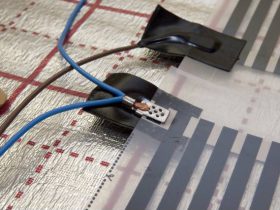

If necessary, the film quality distribution of sex, you can cut the individual sections. But this should be done only by specially designated places. For this purpose there is a dotted line with an image as a "scissors". These areas were subsequently isolated by bitumen coating. It often comes with complete Infrared floor heating. It should also be maintained when laying the distance from the wall in the room, which is at least 100 mm.

Infrared bands are placed on backing.  Between the strips is kept a clearance of 5 to 10 mm. Guaranteed immediate failure of the heating element in the event of bending angle 90 degrees. The wires are stripped from the voltage current up to a distance 10 mm special knife, so as not to damage the wire. The resulting contact is placed and clamped in the terminal. When all done, it isolates bitumen coating.

Between the strips is kept a clearance of 5 to 10 mm. Guaranteed immediate failure of the heating element in the event of bending angle 90 degrees. The wires are stripped from the voltage current up to a distance 10 mm special knife, so as not to damage the wire. The resulting contact is placed and clamped in the terminal. When all done, it isolates bitumen coating.

Infrared heat-insulated floor is characterized by parallel connection. To do this, use copper cables with multiple conductors. Cable diameter should be at least 1,5 mm2. All other components (sensor, thermostat) connected necessarily to quality of the heating system.

As a result of all these steps, we get a full "pie", from which for a maximum of 30 minutes after the inclusion in the network, heat is transferred. The peculiarity is only in the infrared heat-insulated floor, when warming up the floor covering and home furnishings in the room, from which heat the air already passed. Installation does not take a lot of time and money. The main thing - to strictly follow the available instructions for installing one component of.