By screed technology under Heated floor often have to carry out the solution pouring concrete over the heating elements. This is necessary not only to create a level surface under the deck flooring, but also the protection of all components. At the same time in different situations will differ and the thickness of the fill layer. Even the manufacturers in their instructions on the device screed under floor heating electric sidestep the issue. It is with thick and should be defined in the course of laying the components.

Purpose ties

for normal screed characterized by the following features, it performs:

- Protection against external mechanical action of the heating elements and other components underfloor.

- Creating a strictly horizontal surface, necessary for high-quality styling option chosen floor covering.

- Uniform transfer of heat from the heating element to the base floor.

- load distribution on the basis of the pieces of furniture and household appliances.

- "Mediator" in the transfer of heat from the heating elements inside the room air.

But it should not only perform its tasks, but meet certain requirements, including isolated duration of the maintenance period, which depends on the quality of the fill and solution preparation, and the ability to withstand a constant temperature differentials. With all this it should not in any way adversely affect the heating cables or other elements of warm electric sex.

All recommendations from the manufacturers of screed should be maintained at every stage, without forgetting about the optimal thickness screed floor heating. In one caveat to consider the warm screed, that such shading will be more susceptible to thermal expansion. Consequently, you need to create all the conditions for the ability to withstand all obstacles.

recommendations

During the work on the solution casting screed warm electric sex should adhere to certain recommendations, which will not only produce high quality laying of floor heating under the screed, but also to choose a minimum thickness of the screed.

Much will depend on the power of the heating elements in the heating room. Than it will be more, the thicker the need to create a layer fill solution:

- 80-120 W / m2 - tie layer will be up to 20 mm.

- 100-140 W / m2 – 30-50 mm.

- 160-200 W / m2 – 60-100 mm.

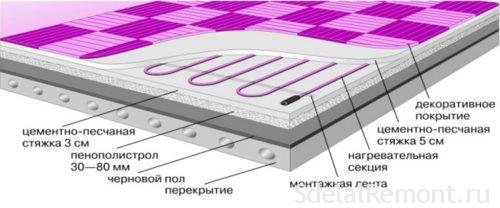

The thickness of the "pie" warm floor

when a electric floor heating Ties thickness should be observed depending on the particular conditions and performance parameters of premises.

But at the same time it draws attention to the, that the thickness of the fill layer will depend on the time, during which the subfloor will be fully warmed. So it is not always advantageous to provide a thick layer of the prepared solution. In this case, it will spend large amounts of electricity to the heating of premises.

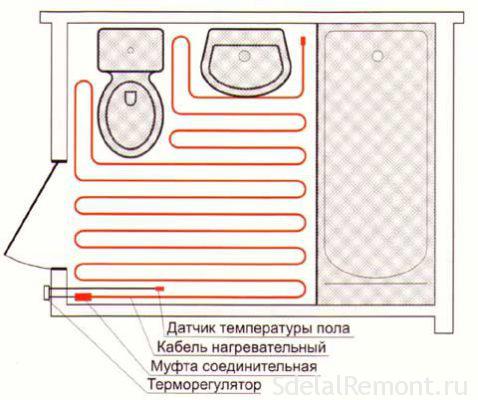

To fill electric underfloor should be several times to check the correct installation of the heating elements, as well as carrying out the wiring and connection of all components. In the following for troubleshooting We have to dismantle ties. All wiring and electrical devices need to be sealed. This also applies placed in a corrugated pipe temperature sensor.

If properly position sensor, then when it fails, you do not have to break the tie for the extraction. He simply is removed from the corrugated tube and replaced with a similar. It is worth noting, what thermoregulator It can not be installed in the same room, where there is a constantly high level of humidity.

Pour half the cable is possible and adhesive solution. But it provides only, if used as a floor covering tiles or stoneware.

rough base

Prior to the distribution of the heating elements for a pre-arranged scheme, you should check and prepare the ground under warm floor.  It does not always meet all the requirements, It has defects such as potholes, height differences throughout the room. With this deal should be, so as not to collide with a weak warm-efficiency underfloor heating.

It does not always meet all the requirements, It has defects such as potholes, height differences throughout the room. With this deal should be, so as not to collide with a weak warm-efficiency underfloor heating.

After removing the old flooring and the dismantling of the concrete base, you can proceed to the alignment with the help of the rough screed. For this purpose the classic sand-grout. For further activities can start after complete drying and curing. Otherwise, the high quality you can forget. The thickness of the screed electric underfloor herein is typically up to 50 mm.  The most important thing, to cover all the irregularities in the substrate and to prepare the surface for laying the heating elements underfloor heating.

The most important thing, to cover all the irregularities in the substrate and to prepare the surface for laying the heating elements underfloor heating.

Further, all unnecessary debris removed from the surface and on the possibility of dust. Here can help cope with the task of building a vacuum cleaner. Above roughing screed laid layer of insulation and subsequent distribution cable or underfloor heating mat. In some cases, floor screed under floor heating with his own hands and arranged on top Infrared floor heating. true, thus somewhat reduced its effectiveness during operation.

Laying of floor heating components

That the system of floor heating fully operational, to fill concrete screed should identify the site of attachment of sensors and the main components. The thermostat is mounted on the wall surface, and as close as possible the existing outlet. The distance from the floor should be at least 30 cm, since the temperature of the base will be somewhat distort the transmitted information.

A temperature sensor is placed in the subfloor, which subsequently pouring the prepared solution will be carried out. It is worth noting here that time, that it is in direct contact solution may fail. To avoid this, the temperature sensor is placed in a corrugated pipe, which leads from the thermostat on the wall. All exposed areas of the flutes are sealed with sealant, that they did not get the solution during fill. Not superfluous will be additionally installed on the end of the tube at the base of a special plug.

The heating elements are placed starting from drawn by circuit, where it will be displayed more and their placement step. Deviate from the drawing is not necessary, since it pre-calculates all the little things. After finishing work with the components of floor heating, they need to check on the performance of, connected to the mains. Measured cable resistance, which should correspond to the data, which are set out in the certificate for it. If a positive result is possible to start directly pouring concrete solutions.

screed

The best option screed performance - the use of special ready dry mixes underfloor heating. They contain all the necessary components, including plasticizer.  This significantly increases the quality of the final solution. Its distribution should be done carefully, not to damage the heating cable warm electric floor. Furthermore, the mixture should be distributed uniformly over the entire surface.

This significantly increases the quality of the final solution. Its distribution should be done carefully, not to damage the heating cable warm electric floor. Furthermore, the mixture should be distributed uniformly over the entire surface.

When filling solution, regardless of, how many ties must be over the warm floor, can not prevent the formation of air pockets. This will help to reduce heat transfer from the heating elements of the base.

As I mentioned earlier, optimal thickness screeds for floor heating should be between 30 to 50 mm. There may be cases, when the minimum thickness of the screed for electric floor heating decreases. But then you have to add in the corresponding additive solution (plasticizer).

Until concrete screed not dry, You can not run a job underfloor. Otherwise, the solution is not able to recruit the necessary strength and grab. For the period after 28 days, possible to start cutting elements protruding tape and insulation damper, and include warm floor after tie. Heated floor after the screed covered floor covering selected one.

There may be cases, When floor space is more than 20 m2 or one of the walls in the length of the room more 5 m. In this case, not only to create different contours of the heating elements, but also to produce screed in two stages. Between the circuits of floor heating are required expansion joints, to maintain the integrity of not only concrete screed during operation of the heating system, but the flooring.

All these details allow us to answer the question, how to make a tie warm floor. Much difficulty does not arise, if you strictly adhere to the sequence of actions and recommendations of the manufacturer. After decking flooring indoor air is warmed up to the required level.