During the construction of civil and industrial projects, in mechanical engineering, shipbuilding, production of agricultural machinery and equipment used by special fasteners like bolts and nuts of different sizes, having certain characteristics consistent with the requirements for strength requirements.

Bolt as an important design element

Bolt - a metal rod, which may be of different length and diameter of the applied threaded rod and the head bounding the fixed form.

A variety of manufactured bolts are classified according to certain criteria and is displayed in the GOST quality and type of steel (Carbon, alloyed).

To improve the service life and shelf bolts used processing products with special protective structures prevents metal corrosion:

- using zinc (coating thickness up to 25 m);

- nikelevımi, bolt, used in furniture manufacture;

- containing cadmium (It has toxicity, It is therefore used only in special cases);

- with oxidation and phosphating technology;

- by coating technology zinc-cadmium shell.

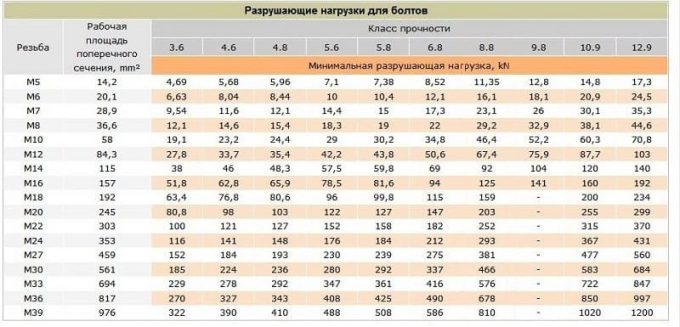

strength characteristics

fitted bolt 11 strength classes, which are governed by the requirements of, displayed in GOST 7798-70 with indicators of 3.6 to 12.9. bolts, has the highest level of strength, made of stainless steel, which is reduced to a minimum content of phosphorus and sulfur.

Bolts that are manufactured according to GOST 1488-84 RF, They are analogous to DIN screws 478, but between the products of these standards may be some differences in size.

Modern standard DIN 478 It contains information about the parameters of the set screws, having a square head and shoulder. Due to the presence of the bead, screw bearing area increases, thus avoiding forcing the head of material and in some cases makes it possible to dispense with the washers.

bolt DIN 478 produced with metric thread M6-M24 with incomplete thread length 18-38 mm. The square has a side of the screw head 6-16 mm. Product height collar 2-4 mm, and the diameter of the screw head of the collar is 13,5-25 mm. The total height of the head with a fillet is from 10 to 20 mm.

according to DIN 478, set screws release strength class 5.8 / 8.8 / 10.9. The material used for manufacturing ordinary steel or corrosion resistant, and zinc-plated steel.

A very important parameter is the strength of the bolt load!

Using bolts intended

Produced bolts based on entry requirements are divided:

- on the engineering used in the manufacture of equipment, equipment, machines;

- Furniture are less smooth the notch of the thread head;

- on the road used for the manufacture of metal fences. The head of the bolt is in the form of a semicircle, but headrest square;

- plowshare on the sphere of application in agriculture;

- for travel - Specially designed for use in the management of construction works on the railway transport.

The use of bolts with regard to the shape of heads

The use of bolts having different shape and size of the planting head products are divided into groups:

- anchor used for installation of structures with high weight, used for installation of doors, suspended ceilings, a variety of lighting fixtures, window frames;

- universal (with hexagonal head) used in the manufacture, construction;

- equipped with a semicircular head used in the manufacture of furniture;

- eyebolts - products with rings instead of fixing head:

- Countersunk head - are used in the production of radio products.

Differences bolts on the rod-shaped

bolt rod can be of different lengths, knurled thread, different diameter of the head and the threaded part of the bolt. Type of bolt is marked - step.

Using different thread pitch.

On thread bolts is applied depending on the technical conditions of use:

- inch made in the form of a triangular profile;

- metric, thread form in the form of an isosceles triangle;

- trapezius has an identical shape, creating strong friction when rotating, which prevents spontaneous loosening nuts;

- Rectangular used for exposed heavy duty bolts;

- Resistant designed for bolts in structures experiencing strong lateral displacement.

Division products in the class of accuracy

Produced bolts are classified by 3 accuracy classes:

- class A - characterized by substantially the same diameter of the bolt shaft and a mounting hole, wherein the opening may have a smaller diameter by no more than 0.3 mm;

- In class (normal accuracy) - the difference between the diameter of the bolt and the hole must not exceed 3 mm, a rod having a diameter deviation of more than 0.52 mm;

- With class - the difference rod bolt and bore should not exceed the tolerance 11 mm.

example

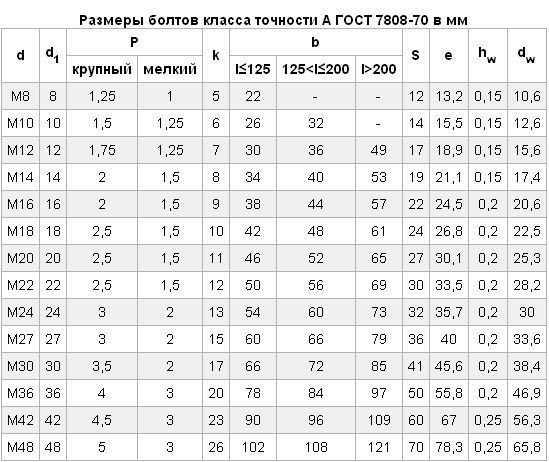

GUEST 7808-70 Bolt accuracy class A Hexagon reduced head, metric thread size from M8 to M48, length of 10 to 300 mm.Ispolzuyutsya for connecting and fastening parts, knots, designs experiencing dynamic loads.

d - nominal thread diameter

D1- stem diameter

P - pitch thread

D - diameter of the head

k - head height

b - thread length

S - size turnkey

e - the diameter of the circumscribed circle, no less

hw- width, no less

dw- diameter, no less

l - length of the bolt shaft.

Designation and marking bolts

For the application of certain information characterizing the quality and strength characteristics of the most commonly used bolt head, which can be applied:

figures - indicating the strength class, indicate the permissible load, which can withstand the bolt.

thread designation - is only indicated for use in product left-hand notches.

letters - indicating the type of metal used to manufacture the bolt. The applied system of fasteners designations in general practice is used 3 options:

- complete designation;

- contracted notation;

- simplified notation,

- which are regulated by GOST 1759 – 87, GUEST 18126 – 94.

The correct reading of the information applied to the bolts help prevent an emergency in case of violation of selection necessary for bolt mounting.