Metal ebb help isolate the joints between the environmental impacts of the window and the walls of the environment, Besides, they attach to the windows decorative appearance. Design looks like a window sill, located outside. It applies a low tide for metal and wooden windows, availability of products significantly extend the lifetime of the window.

Features of castings made of metal

metal tides window, as well as any other materials, They have their own characteristics, Advantages and disadvantages. On the positive properties include the following:

- Ability prolonged use, used as the stainless material, capable to serve for a long time.

- Size can be selected individually, that allows the use of low tides for the non-standard size windows.

- It should be such construction is inexpensive. Acquisition counterparts from other materials typically are not as profitable.

- Ability to choose any one you like color, so that the tide is not only fit into the concept of the facade, but will look harmonious with the window frame.

- It does not require special care.

- easy to assemble.

- It does not lose performance properties when subjected to different temperature regimes.

- Sunproof.

However, the design has some drawbacks:

- If the tide metal, in noise is very strong rain. But you can deal with it, using special tape, which is attached to the surface.

- Summer metal heats.

- If the product has no special protective coating or are not made of corrosion-resistant material, under the influence of moisture, it can rust.

What types of metal flashings are?

timetable for window They may be made of metal or plastic. The first option is preferable and is more common, since plastic is afraid of exposure to high temperatures, as well as a sharp drop them, resulting in rapidly destroyed. Exposed to direct sunlight Plastic parts may fade, it will be very evident. That is why the timetable for metal windows are in great demand. There are the following options:

- Galvanized steel. Tide itself is made of steel sheet of small thickness. In order to protect it from the external environment, it is coated with zinc. This product is not thicker 5 mm, can absorb vibration upon impact of raindrops, inexpensive, but afraid of the impact of acids and corrosive materials.

- Metal sheet coated. Is almost complete analogue sheet discussed above, except for one feature: a polymeric coating acts as an additional protection. The basis is usually a polyester. He does ebb stronger, slightly dampens noise when droplets hit, It protects against the acidic environment. The cost of this type of metal flashings slightly higher. They have a more attractive appearance, but can get scratched, therefore require careful use.

- Aluminum drips. Such materials are most practical to use. They are easy to cut, can bend, wherein the aluminum rusts, therefore additional protection does not need. The material can be painted, that is convenient, if you need to make the item a part of design ideas. However, we must not forget that, if the tide metal, price it below, than that of galvanized steel or aluminum.

The available sizes

The width of the element can be from 9 to 40 cm: it depends not only on the size of the window, but also on the premises of the owner preferences. The length does not exceed the maximum 3 m, However, for very large windows, you can combine several ebbs. The thickness is not more than 1 mm, since it is impractical.

How to install the product?

Install metal flashings is straightforward and can be done on their own. Particular attention should be paid to the accuracy of, since errors can not correct non-compliance with the instructions not always.

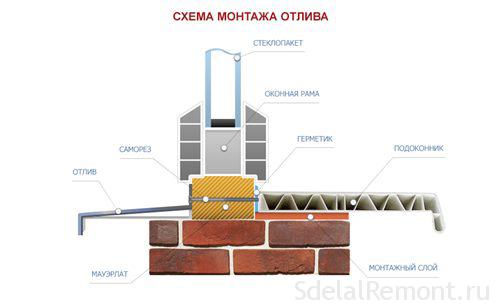

Before you install the structure, will have to prepare a place for work. To do this, remove excess foam, remaining after the installation window, remove dirt and dust, ppredelit, which angle must be placed tide. Before it is installed, recommended gilroizolirovat seams. You can use silicone sealant.

Once you're done, You can proceed to the second phase of operation. First we need to check the design for external shortcomings. If it has obvious defects, you need to take another ebb.

Before installing the product, cut out. This will require his marker raschertit, purchase the appropriate size lateral stubs. cut line should be clear, perpendicular. In order to draw it straight, You can use a great ruler or builder's level. The very fabric can be cut with scissors or metal used for this purpose grinders.

Edge-mounted low tide when closing the window frame. For this purpose it is necessary to get under it and press firmly to profile. The angle of inclination should be approximately equal to 10 degrees. Thanks to this low tide will not accumulate snow, moisture will roll down. Installation takes place by means of screws, so the wall will need to drill the holes for dowels. Step would be about 45 cm.

Caps on the sides are attached with a sealant, it's best to use a transparent. Plugs are used not only for creating a pleasant appearance design, but also to protect the joints from driving rain and snow. Besides, do not forget the installation of a waterproof membrane. It will make the connection and tightness. Impose it on the assembly seam is required before, as the tide will be fixed.

Reflux windowed metal is the most practical solution for mounting, because it can not only reliably protect joints from moisture, but also last a long time, requiring no specific care. This is a simple and inexpensive way to protect the quality of window designs.