Heating in a private home or apartment is not in place, and is constantly being improved. Adding new methods and techniques, which require a certain experience of work. The greatest warming performance space is a system of water underfloor heating. Existing communications are laid in mortar. During operation of the system, heat is transferred to the floor covering, and later into the entire room. Besides this most economical heating can be called.

Requirements for pipes

The coolant is mainly water. But some used antifreeze or ethylene glycol. It is the right choice of pipes will contribute to the effective operation of the whole heating system. Visiting shops, should pay attention to certain requirements, that apply to the material:

- Operation period Duration. In case of purchase of defective products, will have to make their repair or dismantling time.

This will lead to greater financial costs.

This will lead to greater financial costs. - material strength. From it will depend on the operating parameters of pressure, and temperature fluctuations.

- expansion ratio. Than it will be less, it is better. There should not be larger diameter pipe in the floor screed under pressure and elevated temperature. Structural integrity and flooring screed itself can be broken.

- The high degree of heat output. This item will allow to transfer heat into the room with maximum efficiency.

- Environmentally friendly. In case of accident or breakdown, the pipeline should not have a negative impact on human health.

- Bend radius with a minimum performance.

types of pipes

pipes floor screed can be used completely different. Basically classification is isolated by the method of manufacturing materials. When it comes to copper tubes, then immediately should prepare a decent amount of money. These pipes are the most expensive. But they are without consequences laid in screed concrete floor under the floor. strength of the product is very high, It does not allow oxygen to penetrate. The surface of the copper pipe is not exposed to corrosive changes, but now no longer use such systems. Throughout use plastic pipes.

It is important to know, that it is necessary to control the temperature of the fluid in the pipes and prevent lifting up 50about degrees.

The vapor proof plastic tubes used in the polymeric. It is based on such materials, both polybutylene and polyethylene. They are able to withstand not only the internal, but external pressure. In addition, they are also not subject to corrosion. But here's the hardness it just is not enough, since it is easily exposed to external influence, including cutting. For underfloor heating they are used to a lesser extent, although it has a low price.

When mounting polypropylene tubes in floor heating system, it must have a certain temperature level. The minimum rate is 15 degrees.

composite pipes, made of metal, have a high level of strength, resistance to corrosion. They do not differ on the characteristics of the copper pipes, but it is much cheaper. In the composition of the pipe has three layers:

- Interior (polymeric). It makes it easy to transport the heat transfer fluid, protecting the appearance of deposits and corrosion.

- Average (aluminum). It withstands high temperature conditions, as well as retains the pristine form of a tube.

- Upper (polymer). It protects aluminum from external mechanical action.

Advantages and disadvantages

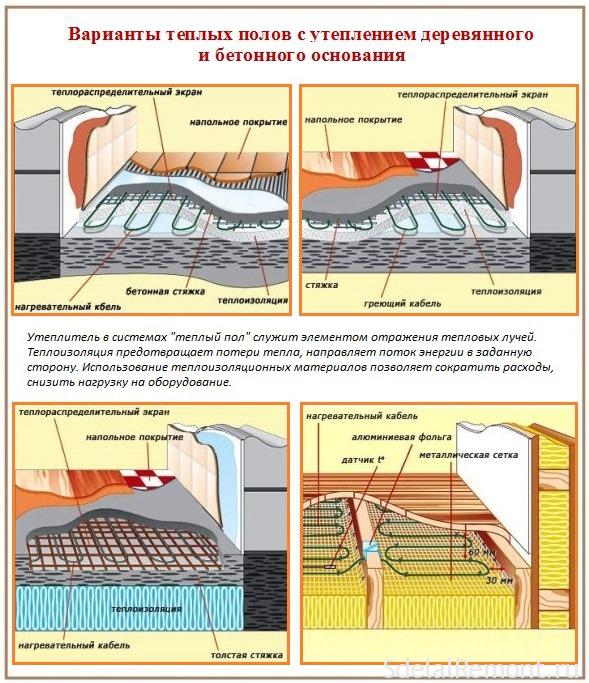

According to the system underfloor heating can say, that all the heat initially enters the concrete screed, that after heating it passes into the room. Not important, which variant is used in the apartment, electric or radiant floor. But the installation of pipes in the screed has both its pluses, and cons, which is to talk more before the start of assembly.

The advantages include:

- Warm air coming from the floor to the ceiling. Consequently, created favorable conditions for walking.

- Rapid heating of premises, than conventional batteries.

- Uniform heat distribution throughout the room.

- The savings due to the large heat transfer area.

But we must not forget about the negative display, which most often occurs due to the fact, that have not been fully complied with casting technology ties and laying pipes. By the circuit pipes it does not have access, but, Consequently, if necessary, repair, will have to break all the tie and remove the floor covering. If the gasket is in violation of the requirements, then there is a big potential for leaks on the downstream floors. Yes, and the installation process requires specific knowledge. Not everyone can make their own arrangement of pipes for floor heating systems.

surface leveling

Before beginning installation of the pipe system underfloor heating should be carefully prepare the base. It must be perfectly smooth without defects, cracks, potholes. Around the perimeter of the room allowed height difference to 10 mm. Subsequently, it is closed all subsequent finish laying the screed.

Before the start of the distribution of the solution, All communications should be routed and put in its place. No debris and even dust on the surface and should not be.

We can not forget about the insulation panel in the case, when the room is located above the basement or garage. Heat should be given only inside the room, and not to spend money on the absorption of the cold air from the bottom. This will help distribute heat in the most efficient.

Pipe laying and fixing

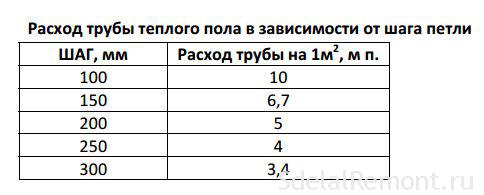

When we proceed to laying heating pipes screed apartment, which were chosen for the floor heating system, it should be remembered, that the distance between turns must be equal. This is a better uniformity will transfer heat into the room. The best ways of laying - spiral (snail) or snake. no joints, infeeds must not be. It must obtain a monolithic section. If necessary to bend the tube at specific sites, best used benders. But everything will depend on the pipes, their plasticity and the possibility of.

Laying heating pipes in the floor must be carried out according to the scheme, which previously performed. For fixing elements to the floor using special straps. They already have the correct diameter for the slots. On individual sites used clips or staples. The most convenient and efficient option - fixing pipes in the grooves, which has cut into the insulation panel. This indicates, that the heat insulation layer must be made mandatory.

underfloor assembly rules

heating pipes in the floor below screed allow to abandon all the usual batteries, which only creates negative for the interior space. Among other things,, in this way, system transmits more heat the room, than radiators, saves money. Radiator becomes flooring. Such a system can be arranged in a completely any room, while respecting the sequence of actions and installation requirements.

There are certain rules, which are assembled underfloor heating. Only when they are subject to heating on the floor in an apartment in the screed will have the best performance.

- surface leveling. To this end, self-leveling floor is carried out over the slab. "Draft" in this case the floor to get rid of irregularities, cracks and other defects. heating pipes in the floor screed will be placed correctly and uniformly.

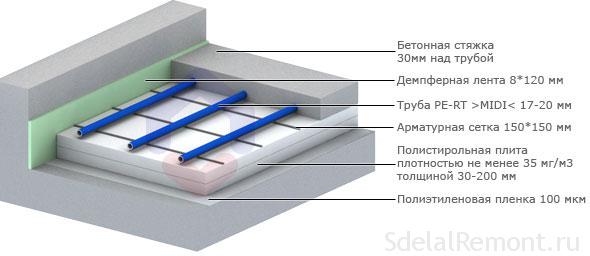

- Apparatus waterproofing layer. As a material commonly used or rolled waterproofing lubricative. If taken mastic, they should be water-based, which in turn will act also as an adhesive for insulation.

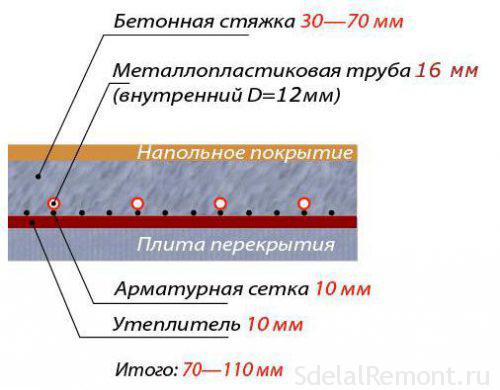

- installation of thermal insulation. An excellent embodiment is extruded polystyrene. He will also serve as the guiding framework for the heating pipes in screed apartments. Minimum insulation layer must be 10 mm.

- The next step is the installation - laying pipes. Avoid breaks, joint elements. The optimum diameter of the pipe used - 1.6 cm.

- Apparatus reinforcing ties. At the same time it draws attention to the material of the pipe for heating the apartment under the screed, since heavy loads, Polyethylene materials such as lead to deformation and damage. But on this stage should talk more.

screed

Heating in the floor screed is effective when properly filling solution. It will depend on the base, its defects, as well as the area of the entire room. Laid pipes must be completely covered with concrete screed. You can not at the same time forget about the joints, without which the floor surface will holes. During heating the solution, coupler may be subjected to deformation. Filling expansion joints is done with polyurethane. Regarding the choice of pipes in these areas, it is best to use corrugated.

The layer of concrete is usually 30-70 mm. It is prepared from dry mixes, which has all the necessary components, fillers, supplements, plasticizers. If desired, the solution is prepared independently. In doing so he must strictly adhere to the proportions of the amount of sand, cement, water and other components. Qualitatively prepared solution affect the screed. If we forget about the proportions and do everything by eye, then later not without cracking, shrinkage areas and other defects. We'll have to dismantle and re-start work. floor warming and the whole heated space will be uneven, and the pipeline itself will not be able to serve the specified amount of time.

This technology is perfect not only for residential buildings, Apartments, but also industrial facilities. After the end of the pouring of concrete floor should be given time to complete its drying. Typically the period is 3-4 of the week. All will depend on the solution.  Once the surface is dry, you can walk on it sander, which will contribute to a uniform smoothness and flatness. Will only make laying a floor covering, variant which is selected for underfloor.

Once the surface is dry, you can walk on it sander, which will contribute to a uniform smoothness and flatness. Will only make laying a floor covering, variant which is selected for underfloor.

The decision on, to fill the heating pipes on the floor, adopted at the stage of the overhaul of the premises. This can be done in the construction of houses, but few have enjoyed this. Significant importance when performing floor screed in flat pipe. Their selection will depend on the quality of the final. They should be fully included in a future tie.

If necessary heating pipes filling in mortar, it should first seek the advice of professionals. They will prompt all the underwater installation of stones, and will point to possible shortcomings in the end. By this worth considering, to get only positive quality.