When the mounting operation starts with the use of plasterboard, you need to take care of the structural strength. What reinforced seams? What used to coat the reinforcement with tape-serpyanku?

Before, how to buy the right stuff, should be familiar with its characteristics. Puttying joints drywall constructions is an important point, which determines the strength generated surface, rigidity, preventing occurrence of deformation, cracks. Let us consider what is needed for drywall putty joints (GKL)? If a few basic types of material, manufactured by different vendors. Each mix has its own distinctive properties.

The nuances in the work

In the process joint reinforcement, may have nuances, which adversely affect the quality of their work. therefore:

- Before Shpatlevanie should close all windows and doors, that there was no draft. With strong air movement of the seam will not lasting, able to give a crack.

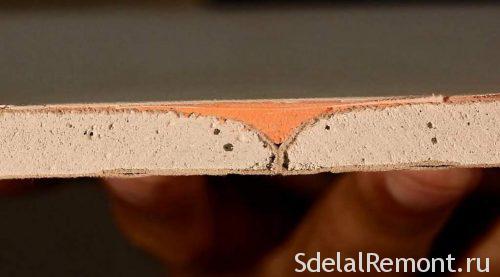

A crack in the plasterboard structure - The room temperature should be more than 10 degrees. Because the joint is not durable, if there was a low temperature.

Flimsy drywall joint - Be sure to reinforce the joints of the drywall in new building, because the house is the "shrinkage" and this has a negative impact on the plasterboard structures.

- Cracks reinforced tape with a special putty composition for preventing its growth.

reinforcement cracking

Reinforcement of joints - a mandatory step in the creation of beautiful and durable drywall constructions. Tape and apply the mixture will create an obstacle to the emergence of cracks, as well as deformation from impact of temperature differential, high humidity, the impact of the mechanical force (punch).

To prevent cracking on the walls of use fiberglass.

Instruments. Materials for sealing seams GCR

Drywall to seal joints needs a set of tools, as well as some materials, without which the work would not be practical, quality.

- A set of spatulas. Spatula with a narrow spatula (8cm.), nabornoy (to 15cm), large blade spatula (to 40cm). It is worth paying attention to the flexibility of the metal. The better the bent blade, the easier it is working.

- Caulking. For sealing joints used special putty, characterized by its characteristics.

- reinforcing tape. Without it, seal the joint will not work at all. This is one of the most important materials in this work.

- Primer. Primer mixture of several functions: It gives improved adhesion to reinforcing tape, strengthening the foundation, protection from moisture penetration plasterboard.

- brush, roller or spray. These tools are necessary for the application of a primer on a plaster surface.

- building mixer.

- Capacity for bonding agents mixture dilution.

a tray for the preparation of mixtures - Net ordinary water.

- Sandpaper to perform grouting after drying putty.

With this set of tools, as well as the right to work materials, reinforcement joints held, without taking up a lot of time, as well as high quality will be achieved, which is necessary for long life plasterboard surface.

Preliminary work with joints

To begin grouting plasterboard with their hands , should carefully prepare all the seams in the drywall surface.

The first step is to test the design strength and location of fasteners. Cap screws must be recessed into the drywall, and itself sheet must be firmly fixed to the frame.

At the joints should not be exfoliated cardboard. If there are pebbles of gypsum, and sticking paper, necessary construction knife carefully remove all, that the joint had a flatness and integrity.

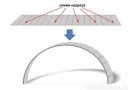

When gypsum boards adjacent to each other have no special recesses, it needs to be done under the knife 45 degrees. chamfer depth of up to 5 mm. This will make the joint strong, a rigid structure. All the dust from drywall seams quickly removed with a vacuum cleaner. Sheets and cover joints primer.

Jointing drywall paper tape come with glass and putty is made only after the preparatory work.

manufacturer Knauf technology for processing joints

Treatment of joints begins, when the room is established temperature and humidity conditions.

The room temperature must not be lower than +10 ° C and should be kept stable

within two days after treatment. Rapid heating and cooling of premises, drafts

during and after the seams are unacceptable.

Prior to processing the joints should be checked for loose plaster building boards

or gypsum sheets. head protruding screws to tighten.

Manufacturing jobs, leading to an increase in humidity in the rooms, It must be completed, since moisture prevents dryness and deforms joints.

Processing seams gypsum building boards using reinforcing tape and

putty mixtures Knauf Fugen or Knauf Uniflot

The joints of gypsum building boards, with all types of longitudinal edges shpaklyuyut using reinforcing tape and mixture putty Knauf Fugen or Knauf Uniflot.

The joints of gypsum building boards, formed or cut longitudinal end

(okleennyh not complaining) edges also shpaklyuyut using reinforcing tape and mixture putty Knauf Fugen or Knauf Uniflot. To do this before installing

gypsum building boards with cut edges by using edge chamfer planing

at an angle of 22,5 ° in 2/3 sheet thickness.

For the treatment of joints gypsum building boards type SHG H2 and applies the GPS type DFH2

putty mixture Knauf Fugen Hydro or Knauf Uniflot (water-resistant).

As a paper reinforcing tape is applied a perforated tape.

When a two-layer plating frame joints sheets of the first layer without reinforcing tape shpaklyuyut.

The procedure for processing interface gypsum building boards, uncircumcised formed longitudinal edges of gypsum building boards:

• dedusting interface;

• applying a first layer of putty and indentation into it reinforcing tape trowel

on the joint center;

• applying a skim putty layer on the dried first layer;

• applying the alignment layer on the hardened putty and dry skim coat.

The procedure for processing interface gypsum building boards, educated

cut edges of gypsum building boards chamfered on at 22,5 ° 2/3 Tol of tires

list:

• dedusting interface (to improve the adhesion of putty with gypsum core is recommended to treat the cut edges with primer Knauf Tifengrund);

• applying a first filler layer, pushing the material into the joint with a spatula and removing excess

fillers from the surface of gypsum building boards;

• applying a skim layer of putty on the hardened first layer and dry and it indentation in the reinforcing tape for a joint center trowel;

• the application of the leveling layer of putty, after the reinforcing tape grabs

with weld surface.

Site installation of fasteners must also be putty. after drying,

putty detected irregularities removed using grinding tools.

Now it is possible to determine the manufacturer of the firm, which produces a special filler for reinforcement.

The types of filler

Manufacturers of various countries offer different mixes for drywall joints. They vary in specifications, They differ in their features. What is to cover up the seams of drywall is best?

Putty Knauf Uniflot for joints

Knauf is a universal putty Uniflot. The mixture is suitable for conventional and water-resistant drywall. Use of blends may smokers with normal and high humidity. However, to create a continuous filler layer on the walls or ceiling is not desirable.

distinctive dignity:

- Strength. Filler for joints drywall comparable with cement .

- Uniflot a light plaster, which makes it possible to use it not only on the thickness of drywall sheets 12.5, but 9,5.

- This mixture can be used for sealing joints without reinforced tape. This reduces the operating time, despite the fact that the quality remains high.

- After some time, for which dries "Uniflot", putty does not transmit nor absorbs water, which is a distinctive feature.

- Due to the plasticity of the seam or crack filler. If a plaster surface otyazhelev, it does not deform due to the created seam.

- If the seam has a gap 2 mm., then no shrinkage solution. At a greater distance, "Uniflot" must be imposed on the joint twice.

The disadvantage of putty can be considered impossible to use on the street.

The use of fillers

Caulking for sealing drywall seams manufactured in powder form, having a distinctive hue. The solution is prepared in small batches, at a temperature range of +10 to +35 degrees. The final solution should be applied to the seam, not waiting for 25 minutes, after which it begins to freeze.

To achieve a more durable seam for gypsum surface can apply the reinforcing paper tape «Knauf». This is mostly done in places, where drywall constructions will otyazhelev piece of furniture (television, Water heater).

Knauf Fugen

The joints drywall putty?

Plastered "Fugen" made on the basis of plaster and is designed to work indoors. With the help of special additives, putty is capable of creating a barrier to moisture. It is used for reinforcement of drywall joints with reinforcing tape.

Distinctive features:

- Fugen has a fine-grained structure.

- Minimum layer superimposed putty 1mm, maximum layer - 10mm.

- Minimum temperature, in which you can work with putty +10 degrees.

- During 30 minutes should develop the entire solution. After elapse solution thicken well-read.

- The shelf life of Knauf Fugen 6 months. After the elapsed time the mixture loses its elastic properties.

Reinforcement of joints made with reinforcing tape "Knauf" imposing 2 layer of putty.

The use of fillers.

Application is wide. It is used for reinforcing joints in the concrete floor. Fills the seams of drywall constructions. This is probably the most inexpensive and popular option with which you can get rid of any cracks on surface GCR.

Fugen is used when installing the painting corners. Also applied as an adhesive when aligned walls gypsum boards.

Semin CE-78 filler for sealing joints GCR

The seal the joints between plasterboard?

Semin grained putty, allowing to carry out work at low temperature conditions by +5 to +10 or higher and high humidity. The main distinguishing from other quick setting mixtures is, which reduces the time for reinforcement.

Produced coat in dry form and paste.

For reinforcing seam Drywall should apply reinforcement tape. Caulking is applied in 2 layer. After applying the first seam to be, without waiting for drying, fix the tape. Followed by a second coat of putty.

After drying is required to carry out the cleaning using sandpaper.

The finish coat polymer JS weber vetonit

Caulking based on polymers applicable for the reinforcement of joints with reinforcing tape, and for continuous shpatlevanija walls and ceiling with his hands.

It has versatility, excellent adhesion performance, prevents the appearance of cracks. The filler composition includes ground marble, It gives the advantage that immediately after the putty applied finishing agent: painting, wallpaper.

distinctive feature: after mixing the solution, time to work with him - 48 hours. But, when applied to the surface layer of 1 mm. required 3 o'clock.

The negative feature of putty - is not waterproof, therefore it can not be used in rooms with high humidity.

VOLMA SEAM - TDST

What putty suitable for sealing drywall seams?

Such as a putty Volma seam has a base of plaster and is only suitable for interior works with gypsum seams, and work with surface cracks appeared. Gypsum plaster Volma alignment permissible surface roughness to 5 mm., which is a distinctive feature. Work with gypsum putty can be at temperature +5-+30 degrees, there may be humidity.

Applying Volma for reinforcing seams, It requires the use of a tape-serpyanku. Caulking is applied in 2 layer.

Reinforcement of joints - an important stage in the creation of an integrated single construction of plasterboard, to be strong, beautiful, untouched for a long time. Of great importance is, some filler employed in reinforcing joints. This depends on the temperature, humidity, as well as the reinforcing tape used or not.

More detailed instructions sealing of drywall joints their own hands.

In addition we offer watch a video on the sealing of joints GCR.