- Tips for Choosing

- Dowel-nail for GCR

- Classification of dowel-nails

- Installation differences

- The dimensions of the dowel-nails

- Technical indicators dowel-nail

- What is a plug-metal wedge

- Features of the application wedge anchor

- factors, affecting the structural strength

- Grounds for the dowel-nails and anchor-wedge

- How to be fixed to the wall profile

- Installation of the guide profile

- Mount hangers to the ceiling at drywall

- Video how to mount suspension

- mounting Features

- helpful hints

When installing the lightweight suspended structures using dowels, nails - ready fasteners. They are easily and quickly mounted to the wall, and they hung the shelves, pictures, mirror, lamps, etc.. Widely used in the repair and finishing works, for example when installing plasterboard frame.

Tips for Choosing

Dowel-nail consists of two elements: dowel, which is inserted into the hole in the wall, and nail, which is driven or screwed into the anchor in the presence of the thread on the rod. The cap has a slot, usually, Phillips screwdriver. Dowels of polypropylene suitable for installation in heated rooms, nylon - able to withstand freezing temperatures, It can therefore be used even in the street.

You can use the plug-nail for concrete, brick and aerated concrete, all depends on the design of anchors. According to this principle, the following types of.

- spacer - fixed through the expansion sleeve in the hole, its raised surface limits movement of dowels.

- Universal - mounted in the hole due to the node, which is formed by twisting.

Buying plug-Nails, pay attention to their the size. The diameter may be from 5 to 8 mm - the more he, especially heavy objects can withstand fasteners. The most common anchor nails for fastening profiled frame of gypsum in concrete the size of 6x40.

The length of the nail may be from 40 to 120 mm - than it is longer, the more reliable is to keep the suspended structure. also consider fixing the amount of in the package and make choices based on the volume of work coming. If you need a story one shelf and a few pictures, enough packaging 6 – 10 pcs. When you need to fix a lot of things, better to take the items with a reserve, eg, 100 – 150 pcs.

Dowel-nail for GCR

applying drywall, should choose the right fasteners. On this factor depends not only on the strength of structures created, but look, design-life period, its specifications - whether heavy with this design different objects. For the installation of the GCR framework. The type and number of selectable dowel-nails depends on the type of frame, selected profiles, they differ in the thickness of the material making up the, materials, wall and ceiling. (foam concrete, coquina, Concrete, bricks, etc.)

For the installation of the metal frame are acquired not only screws, but plug-Nails. These fasteners provide all carcass strength under plasterboard. For use of these fasteners must be acquainted with their characteristics. Improper use can have a negative impact on a metal frame.

Classification of dowel-nails

To purchase the plug-Nails should take into account factors:

- The estimated load on the fastening element, on the surface itself.

- ground, to which will be attached dowel-nail - Concrete, brick.

- Surface - ceiling, wall.

Fastening element neodnoobrazen and available in various sizes, structure.

Installation differences

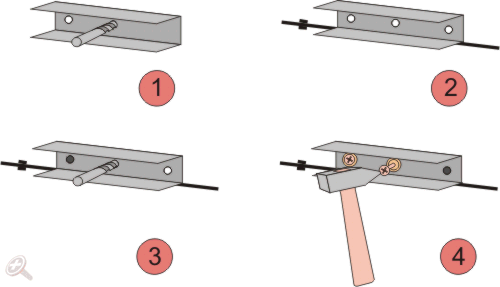

Depending on the design structure of the dowel nails need to work with different tools.

Manually fixing dowel-nail - it uses 2 kind of dowel-nails with a different structure. Nails are driven into the non-threaded ordinary hammer. Threaded - require a screwdriver for screwing or screwdriver.

Fixing construction-mounting a gun. For this type of mounting dowels, nails applied to a metal sleeve. They are made with the expectation of greater weight.

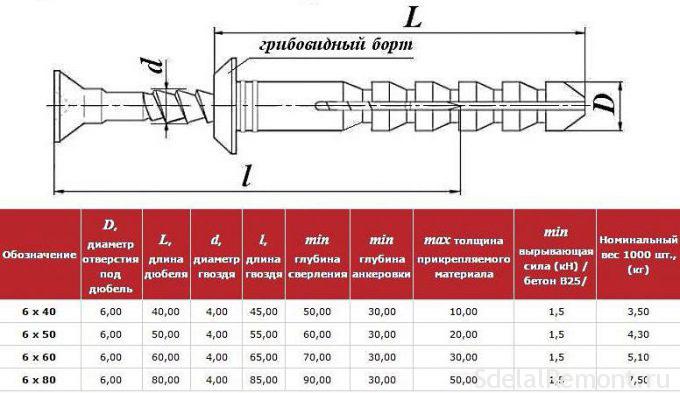

The dimensions of the dowel-nails

The fastening element is made of different sizes. Depending on the focus should acquire dowel-nail desired size. Fasteners marked by two digits: It shows the first diameter, second - fastener length.

| The size of the diameter / length | Fixing length | The length of the nail | Minglubina during installation through | Max Thickness material mountable | Weight 1000 PC. per kg. |

| 6/40 | 4 mm. | 42mm. | 50 mm. | 10 mm. | 3.3 |

| 6/60 | 4 mm. | 62mm. | 70 mm. | 30 mm. | 4.89 |

| 6/80 | 4 mm. | 82mm. | 90 mm. | 50 mm. | 7.28 |

| 8/60 | 5 mm. | 62mm. | 70 mm. | 20 mm. | 8.5 |

| 8/80 | 5 mm. | 82mm. | 90 mm. | 40 mm. | 11.02 |

| 8/100 | 5 mm. | 102mm | 110 mm. | 60 mm. | 13.78 |

| 8/120 | 5 mm. | 122mm | 130 mm. | 80 mm. | 16.53 |

| 8/140 | 5 mm. | 142mm | 115 mm. | 100 mm. | 19.3 |

| 10/100 | 7 mm. | 102mm | 150 mm. | 50 mm. | 15.32 |

Technical indicators dowel-nail

According to records GOST 28457-90 produced plug-Nails. They are processed - hardness 53-56HRC. But there may be deviation of 51 / 5HRC.

- The rod may be curved at the factory defaults: with a length of 50 mm. - 0.1mm.krivizny; length of more than 50mm. - 0.15mm.

- On the nail should not be layers of logs or cracks. The nail should be sharp, if stupidity 0.8 mm. - it is considered unfit.

- On the edge of the nail can be multifaceted.

- A nail can be puck. On its shear force is necessary to 0.3kN.

Dowel nails manufactured with corrosion-resistant zinc layer. It should be no less than 6mkm.

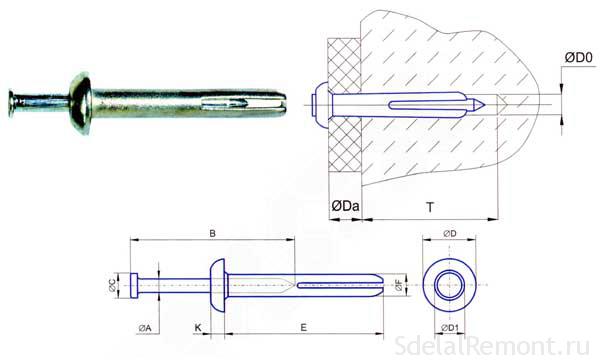

What is a plug-metal wedge

This fixture is called the anchor-metal wedge. It is made of metal. Translation of the word "anchor" as an "anchor".

Metal anchors for drywall has a different installation technology. The movable part fastener is driven hammer, whereby the wedging occurs in the surface of dowels.

Manufactured according to GOST 2 type metal dowel for drywall: 6/40 and 6/60, Where 6 - the diameter in mm., 40(60) - length mm. In the sale of a wedge-anchor is supplied in packs - 100, 200 PC.

How to score a metal wedge anchor quickly punch, watch the video.

Features of the application wedge anchor

The anchor-wedge made from galvanized steel or stainless material. Used carbon steel, covered with white or yellow zinc. At the head of the anchor is put a sign manufacturer with an indication of the applied metal density.

Basically data wedge metallic fasteners are made for fastening profiles or hangers to the base and is the recommended fastening.

Wedge-anchor is manufactured as a metal rod. At one end there is a locking cap, and on the other wedge-shaped spacer trailer. When mounting hole in the done anchor is placed and the hammer is hammered movable part. In this case, the wedges in different directions, thereby fixing the fastening element in the ceiling. Wedge Anchor is particularly reliable attachment to the base.

factors, affecting the structural strength

In order to anchor Wedge had a long shelf life, and maintained strength, there are some factors, affecting these indicators:

- The anchor is driven into the wedge-base, having no voids. Thus appears fastening strength.

- When moisture concrete base will constantly absorb moisture, because of what may appear premature corrosion of metal.

- If the base, in which is mounted a wedge-anchor is constant pressure (motion, vibration), shortly wedge break out.

- If left movable part above the surface - the core, it means, that the anchor is not fully opened. When this life is limited.

- For unacceptable ingress hardware chemical solutions. They will destroy the fastening element.

comparison table, which can be used to determine the strength of anchor attachment-wedge:

| Name | 6/40 | 6/60 |

| The diameter of the anchor wedge, mm. | 6 | 6 |

| The length of the wedge anchor, mm. | 40 | 60 |

| Maxtolschina fixed by material, mm. | 5 | 8 |

| The diameter of the drill holes for, mm. | 6 | 6 |

| Minglubina holes for anchor, mm. | 45 | 65 |

| MinKN rips strength concrete B25 | 3.60 | 5 |

| Weight 1000 PC, kg. | 10.70 | 16.05 |

Separately, it should be noted that all fire safety suspended construction relies fasten metal wedge anchors.

Grounds for the dowel-nails and anchor-wedge

To the fixing member has a long service life, should know what should be the basis:

- Reinforced concrete ceiling floor - slab apartment buildings.

- Concrete - the floor in the apartment or poured concrete in a private house.

- brick. There are several types of material: ceramic, silicate, clinker brick. Each material has a density, It depends on the length of service of fasteners. With such a material may be encountered in private buildings.

- foam concrete blocks. In the absence of their cavity, You need to know the density of the foam block.

Dowel-nails, Wedge anchor can not be mounted on wood, as well as in the walls of the foam block and other hollow materials. Since the spacers are not fixed in the base, but mainly in the void, that will not give the required strength.

How to be fixed to the wall profile

Before secured to the wall metal profile, should have a set of tools and materials:

Profile - guide profile mainly galvanized. This gives reliability to create designs. The calculation is made using the online calculator or on its own. Material is required to take stock of.

Dowel nails for fastening the profile - for solid wall size 6/40. If it is based on a tree, then primenimysamorezy 25mm.

Drill with drill 6mm. screwdriver. Before using electrical tools, required to calculate the load on the wiring.

Shears for cutting metal. In the process of mounting the guide profile is sometimes necessary to make an incision on the metallic article or cutting.

Installation of the guide profile

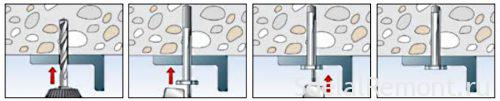

To carry out the installation guide profile requires the prepared surface with the finished layout. How to fix the rail to the wall? Installation is carried out in the following sequence of actions:

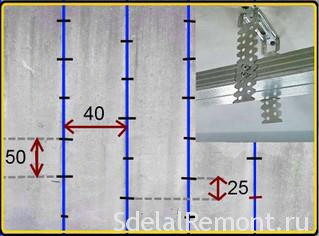

- The first thing the guide profile is applied to the markup (line can take place both from the inside, and from the outside - depending on the emerging nuances)

- Next, the profile requires space for future noted fasteners. Mainly from the edge of the profile is required to withdraw 15 cm. maximum, second fasteners located at 25cm. from the first, and so on - every 25cm.

- In the absence of holes in the profile, they are doing their own. Even, if there are data marked space plant, According to the masters, should be exactly in the middle between the holes to make a single structural strength.

- The diameter of the drill should be 6 mm, and its length 50 mm. if the drill is longer, should it outline border, it is easy to make a tape or adhesive tape.

- In both made aperture in the base of plastic and the dowel is inserted in the profile. Hammered into place it with a hammer. This should be done carefully, since deformation can occur during installation. Then the plastic part will become worthless.

- After installation, the first part of the plastic dowels using a screwdriver mounted nail with thread. The deeper part of the nail integral part, the more it opens the entire locking fasteners special antennae.

- If the profile has a greater length than is required it is cut with scissors, metal.

- If you want to dotochit profile, then you can use special extenders.

- On the border sections should be at each end of retreat 15 cm. and to fix the guide dowel-nails.

Screwdriver should not be put on a great rate, not to drive a nail greater position in the plane, wherein the bend profile.

The guide profile is an integral part of the entire steel Drywall, so it should be strong fixation, quality.

Fixing profile on the ceiling or fixing frame walls under GCR, similar in its technology.

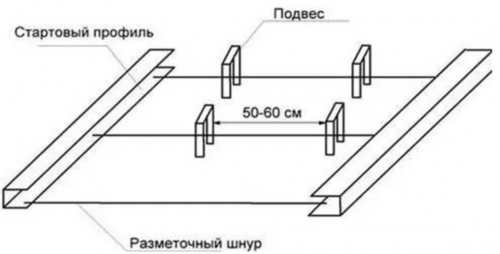

Mount hangers to the ceiling at drywall

The suspensions are attached to drywall constructions? Many of the answers to this question is "used dowel-nails". It is not right, after suspension takes on the burden of all plasterboard ceiling. When attaching gravity, eventually anchor the nail does not stand up and out of the surface. The result is sagging and deformation of the ceiling. According to experts, best fastener is a wedge-anchor. How to mount suspensions for Profile? For durability erected structure anchor wedge-metal, size 6/40 fixed in the side openings suspension. Installation is performed as follows:

- By target marking is done on the ceiling hole 6 mm., the depth of the hole - 40 mm.

- This hole is freed from dust (it can be to blow yourself).

- To make the hole puts the hanger.

- The ear suspension and the hole is inserted to lock the anchor wedge-.

- After the usual hammer hammered protruding rod. With each blow he still tighter comes to the concrete surface. This indicates, that the anchor elements to straighten in different directions, all hereby fixed fastening element.

Installation takes one anchor 10 second time. This fixation of hangers most robust in comparison with the use of dowel-nails.

After some distance to mount suspensions for Profile? Of suspensions depends the strength of the ceiling plasterboard. Hangers mounted on the marked line, designed for ceiling profile. On this line through each 40-60 cm. attached suspensions anchor Wedge. The distance depends on the manufacture of suspension material. If the metal thin, then respectively distance is 40cm.

Allowed to use dowels to create a box on the ceiling. This design does not aggravating circumstances dowel-nail of the small weight gypsum boxes.

Video how to mount suspension

mounting Features

When installing the dowel-nails profile of the walls may be some difficulties. That it was not to be familiar with certain nuances:

- When installing a brick wall should be to determine the place dowel-nail. If the hardware gets to the border (in solution) between bricks, then there is a strong possibility, he pops. Since the solution can be scattered.

- Before drilling the wall should know exactly that there are no wires wiring. Otherwise, a short circuit occurs.

- If the wall is held metal fittings, it also has a negative impact on the hole breaching.

- For correct mounting dowel-nail is required to make the hole diameter in the same, as an anchor (6mm.).

- Drilling wall nuzhnona low speed, the material from the surface did not come out in one piece, thereby forming a large hole.

- When driven anchors restrictive cuff will not allow the attachment member to fall into the hole. Therefore, the score should be carefully plug.

helpful hints

If the hole was larger and the dowel does not hold, it can be corrected in the following ways:

- next tighten the screw;

- if possible, to drill large diameter with the choice of an appropriate dowels;

- Insert the plastic anchor and drop back a little foam. During the night it will increase, squeeze the plastic part and hardens. Only after that can be screwed to the nail and remove the excess foam;

- squeeze into the hole liquid nails;

- plastic insert into the hole of the dowel-nail, apply a plaster. He dries per night, after screw nail.

On the ceiling structure for a suspended ceiling is better to use an iron anchor wedge, because in case of fire, it does not melt, and holds the metal structure. And to secure the direct ceiling hangers is the best embodiment of the retention.

But, If the alignment is performed drywall ceiling in the old pre-fabricated house, We can then apply nail dowel-plastic. He is better wedged and keeps the metal frame.

In addition, check out species dowels for attachment directly to the plasterboard sheet.