Knowledge of modern technologies and methods of work with electrical fittings, so whether it is necessary? Yes, how to connect the electrical wires need to know.

This can be useful when installing, laying of any power supply systems. Are wiring burned, need a replacement of the lighting unit equipment or new equipment. Such knowledge may not be necessary, but it would be better to know all the common methods of connecting electrical wires

Application in Terminal Block chains

Terminals - is electrical products from electrically non-conductive material, which is inserted inside the conductive sleeve, having a pair of screws at opposite ends. They serve for fixing wires. An excellent choice for implementing modern method of connecting wires.

When choosing a reliable connection of wires is important to remember: terminal blocks are available with different holes, many cross-sections.

This method is almost always used to connect to any type of distribution boxes, during installation, installation of wall and other fixtures. It is suitable for installation of most devices, switches and sockets. Mount network using such fittings easily, just in the hole to be inserted bared ends and applying moderate force, securely fasten screws. A wire should not be squashed by. Having examined how to connect electrical wires via terminals, worth exploring other equally reliable way.

Evaluation method of terminal: Excellent quality of attachment. The price is acceptable. Bright enough and easy installation. A good opportunity to connect different wires, eg, aluminum and copper.

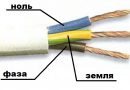

Sometimes terminals themselves do not sell in a proper workmanship, which threatens their breakage during installation. Connectivity is not more than two cables one section in one nest. Be sure to read how to connect the wires by color.

Blocks is not recommended to combine and aluminum stranded chain. This is due to high friability of aluminum wires and conductors themselves great flexibility of the core wire. But overall a decent method.

spring terminals

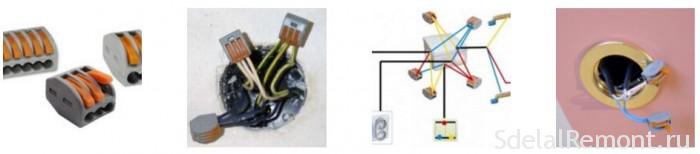

Quick installation of electricity sometimes needed. for example, hold temporary lighting to the balcony, terrace, summerhouse. Spring terminals wago, great product for carrying out such work. Modern and of course a reliable method of connecting wires. Although the market recently they Electrical Accessories, carry out installation with spring clips quickly and it is important to, conveniently.

The main difference application terminal blocks themselves Vago: connect any wires to the electrical box of convenient, than the twist. Here a unique clamping mechanism is used for high-quality installation, rather than a simple screw. Manufacturers produce as disposable, and reusable systems Vago.

- In the normal version is used product for single use, during renovation work in the future can not be restored. it is removed, and instead put new.

- Reusable wago terminals are a bit more expensive, but using them can be collected several times sever contacts, rewired the circuit to suit your needs. This speeds up the repair process or mounting of permanent and temporary networks. A simple lever-type mechanism provides the advantage, it is possible to carefully, but quality fix any wire, without damaging or passing.

With Vago implement most simple bond, you must clean up the insulation and insert the desired wires into the mounting hole. clamp lever. It is important to calculate the load on the wire calculator online.

Evaluation system clamps wago: A unique opportunity to combine all, aluminum, copper and other conductors. Present embodiment of the compounds of multiconductor cables concurrently (two or more).

Universal terminals allow wago, without damaging, fix any thin stranded wire. Another plus, compact size shoes.

Excellent quality and durability. The block type is Vago process opening, giving access to a screwdriver with voltage indicator. The operation of any electrical line can be checked at any time. maybe, one drawback is - a considerable cost of the terminals themselves. But this type of connection wires, the most modern and fast.

Insulation using PPE caps

Decryption is not complex products, insulating connecting clamps (YOU). They are ordinary nylon or plastic caps, having an internal lock.

The simplest type of connection wires, it is performed after the twisting of the conductors themselves, Year. The caps are often used for connecting wires in the junction boxes, for marking the correct color connections.

Evaluation of the use of such products: Fairly low cost of PPE. Application safe material eliminates inflammation wiring. easy installation, We put on the twisting of the wires and you're done. These caps have a large range of colors, that is convenient. Of course, if the wires are color-coded, Sizov from the color it is possible to define or simply to note, zero, phase and other necessary highway grids.

There are drawbacks: Inadequate fixation. Stranded wire type can be mounted, Only after the welds.

Installation of networks by means of sleeves

This embodiment pretends to be the most reliable method for compound. For any loads and the quality of wire.

The conductors are inserted into a tube - sleeve, and crimped with a certain force. there is one, but. wire cross-section must not exceed the cross-section of the mounted cartridges. Insert and crimp the clip, carefully insulated sleeve shrink tube, or by using other insulation materials.

Overall rating. An excellent way a reliable connection of wires. The direction of the conductors may be on different sides of the tube or to one side. Sleeves are quite inexpensive. A good way how to securely connect the wires to each other.

There are drawbacks. Single use cartridges, they are not collapsible. For the production of such works will need a tool: Pressing pliers, which is also used as a special tool. They removed the insulation. They have in the arsenal there is crimping tool, and electrical work took a little more time.

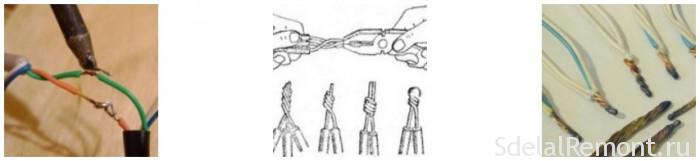

Soldering or welding wire

This method is reliable. Typically such a method of connecting the junction box, It implies first sweep, and twist the ends, after being dipped in a heated solder. The compound of aluminum with aluminum wires preferably carried out by brazing. They were then isolated using Heat-insulating tape or.

Strongly recommended to immediately cool the soldered wires in water, microcracks, arising from this type of cooling, affect the quality of the compound. They are not durable.

Evaluation of soldering method. He gives a strong chain of contacts and excellent quality, no roads, he is the most reliable way to connect to the electric wires are wired in a box.

technological disadvantage. Without soldering iron can not do here. The speed of work is not high. Compound naturally not releasable. Therefore, that the solder do in a pinch, using more modern methods of connection. Among the artists he had long been unpopular, because it takes longer.

There is also a frequent method of connection of electric wires, welding. process similar, but it requires the use of special welding machine, naturally, and certain skills.

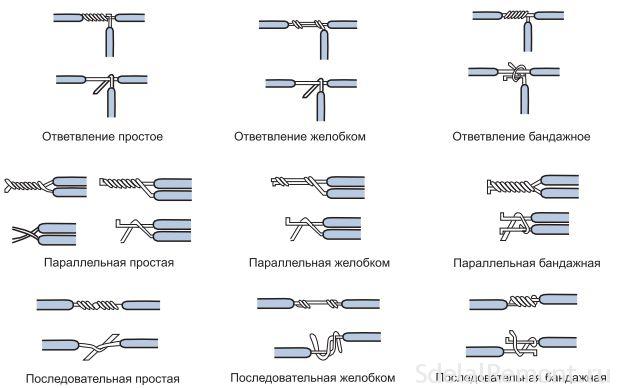

Method stranding contacts

Not new, you can say "antiquated" method, it consists of a helix lived together. The essence of all work is, to twist the bare wires with a pair of pliers, and the place lay insulation cover. here, perhaps, and all the ways of twisting wires.

Qualification of this process the compound. The high speed of installation works. Expensive part is minimal.

shortcoming. Never connect together different twist on the composition, copper and aluminum wire, inevitably oxidation. According to the regulatory framework of bond wires torsions in the junction box, not recommended for use in areas with combustible materials, high humidity, basements, as well as in any home, built of wood. More details about the twisting method electrical wires. Be sure to recommend to watch a video on how it is better to twist or terminals Vago.

The clamping device for "nut" wires

Such a device is simply cable clamp, having inside two plates and several screws utjazhki, usually in the corners. Enough wire to tie itself to the plate. Then put on top of the shell karbolit.

evaluation. A great option how to connect any electrical the wires in the junction box, large and medium-sized. Definitely, These types of products are quite comfortable and have a high degree of protection. It allows you to quickly connect the wire to the track by a thick section and without breaking it.

disadvantages. Dimensions allow installation of only large distribution boxes, billboards. Over time, relax the screws.

Council: Choosing hardware and method, Please note the following:

- Work is necessary only insulated tools, use protective equipment.

- On the shield off or counter necessarily post a warning sign, "do not turn on".

- Connecting electrical appliances to carry out according to the attached instructions.

The main types of wire connections, you without problems will pick the option you want. And with simple hand tools and diagram, independently be able to mount it. In details how to make the installation of the switch box right.

Video on proper wiring