Poured floors are starting to get increasingly popular because of the large number of positive aspects of its use and exploitation. It is based polymer, which is able to get into every pore of concrete, to end up with a high quality and robust coverage. It can be used not only as a topcoat, but also sub-floor. It all depends on the wishes and fantasies.

Main characteristics

Polymeric self-leveling floor It has a number of advantages, which are based on the technical characteristics. Among these properties, It is to provide the most basic of them:

- The robust structure. Due to this surface is not afraid of any external load. The strength and toughness of the filler contribute to increase life of the floor. Even with a constant load on it after 30-40 years after installation, he will be able to show all their original quality.

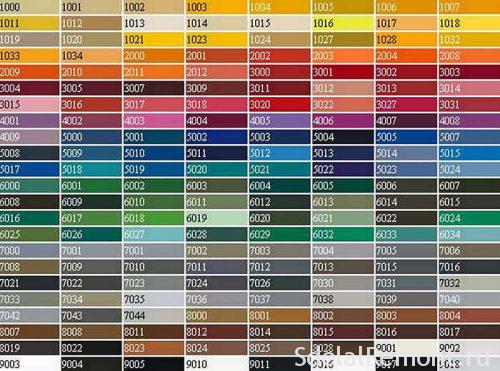

- A huge number of shades, you can choose the appropriate color schemes. Any combination can be matched to the specific design of the room.

- A high level of fire safety. Besides, it is used in completely different areas with different indices of humidity, temperature.

- During any chemical cleaning agents can be used, since they are not afraid of the coating. Cleaning itself does not take much time and effort.

- Regardless of external factors in the environment do not enter hazardous substances. They can only be encountered when the filling device and the floor until dry.

- Thus formed does not contribute to the subfloor mildew and fungi. You could even say, that is all reduced to zero due to the components of the mixture to a cooking solution.

- After mounting on the surface is not the joints and irregularities. It becomes perfectly smooth, does not require additional alignment.

- Rough coating has a wholly level sealing.

- Adhesive properties increased, It is allowing them to easily adhere to the ceiling, to which you are pouring.

All of these characteristics are markedly different cement self-leveling floor from other species. Scope also is more common. In addition to industrial facilities, a perfect base in warehouses and even in living rooms. On each floor the filling characteristics will depend on the chosen mixture.

Finishing is carried out very easily and without much knowledge. No expensive tools are not used, which reduces the overall costs. the main thing, the device of polymeric floors in line with the instructions.

Classification

Division Self-leveling floors It can be carried out in many directions. The most basic of them - the content of the mixture, used to work. It may be noted:

- epoxy.

- polyurethane.

- methyl methacrylate.

- cement.

They should be more detailed, to learn about the properties and the many positive aspects. No harm will learn about the future of the thickness of the base. It is determined by the rough floors. When it is smooth and there is no noticeable pits, then apply a thin layer floor, layer in 1 mm. More common is the self leveling embodiments. Their thickness is 4-5 mm. If the surface into as many bad, that requires a quality alignment, then already have to fill highly filled version.

Appearance future floor coatings also play important when choosing a particular embodiment the mixture.  This may be matt or glossy surface. true, not all customers are happy is a glossy surface, because very quickly it begins to scratch, and loses all its beauty.

This may be matt or glossy surface. true, not all customers are happy is a glossy surface, because very quickly it begins to scratch, and loses all its beauty.

Any type of self-leveling floor can be decorated with various additional elements, are just stacked on the base and filled with translucent ready solution. So that, when a person thinks about, how self-leveling floor better align the floor, choose a few and it all depends on the views, preferences and financial embezzlement.

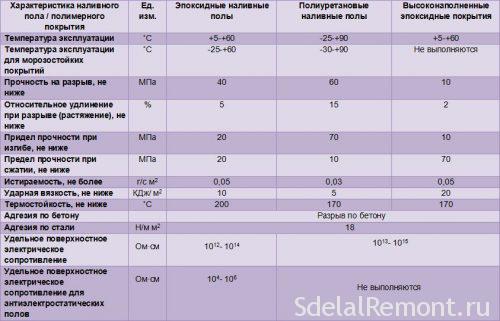

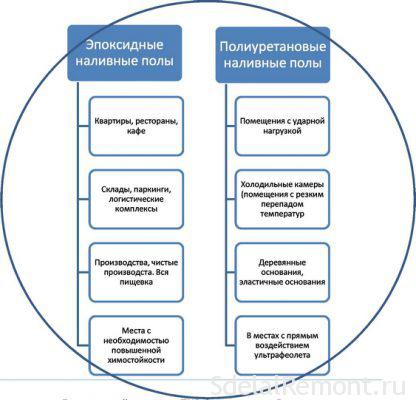

epoxy

Among basic properties, which has epoxy self-leveling floor, It stands out not only, fortress, rigidity, but also the fragility. With all this, they can be used at different temperatures, oscillation which will be in the range of from 0 to 50 degrees. But here is the fragility of some displays such floor of the overall positive coloring. This indicates, that efforts should be made, that on the basis of self-leveling floor went very well after mixing, since it is not very flexible. After drying and, if not stacking technology can even appear cracked, affecting the appearance.

polyurethane

If you need beauty and excellent design surface, it is suitable polyurethane self-leveling floor, resistant to various mechanical influences from outside. Furthermore it is able to withstand any Chemicals, while remaining completely eco-friendly and harmless to humans and the.

Any frequent falling and rising temperatures filler such floor covering can withstand over a long period. But this does not prevent them to be installed in the office premises, as well as apartments and private home ownership. You can not just fill the small space, but also large areas, more specifically for shopping centers.

cement

such material, for self-leveling floor cement attached to the quality of water resistance. This is somewhat different from its simple plaster version. This base fit perfectly under the warm floor, which have become increasingly equip.

When mounted self-leveling floor screed is able to close numerous irregularities on the slab, reaching even to the height 8 cm. The most important thing to choose the optimal composition of the mixture, applied for individual case. If there is no choice of their future skill solution, better to turn to specialists.

Technical self-leveling floor used for laying under the rough coating covering the concrete material. It can not be applied as a final coating because of the low strength characteristics. But as a base layer carries the full set all functions and tasks. The thickness of the base layer may range from 10 to 80 mm.

The basis of self-leveling floor, made with a middle layer thickness - cement. Durability increases immediately, but all the same layer is not able to be the last layer. All of these options are covered in the future or have a suitable layer, or act as a base for the flooring planks. In any case, the filler cement floor dries within 5-6 hours, then it is possible to start laying a floor decorative elements.

Somebody think, it is possible in the concrete floor to add more water, and it will become a self-leveling floor. Initially, and he looks that way and will look. But after drying immediately climb disadvantages - a huge shrinkage, cracks and other negative consequences. The liquid sexes for fluidity meet polymers, included in the.

gypsum

The main difference of this embodiment of the device topcoat floor - Low cost. By itself, gypsum does not have the high level of prices. They can cost even less, than compositions based on cement. Almost all manufacturers provide a single composition of the mixture, to pour plaster self-leveling floor. The only deviation - alfagips, It is a high strength material.

It can be mixed and a filler as a fine silica sand, what, generally, It contributes to a better spreadability on the surface, plasticity. The latter property is important, to avoid cracks after installation.

If the apply special grade of gypsum, it is possible to obtain a strength, exceeding the requirements of building regulations. Durability will reach 30 N / mm2.

The solution mixture was added to the cooking liquid required amount sufficient. It is very important to keep proportions, exposed from the manufacturer. Most often, they will be registered in the package itself ready mix. After installation, you can in a few hours safely and without fear of moving on the surface. Ved gypsum has high drying speed.

The main disadvantage of plaster self-leveling floor is a low level of water resistance. Among the flooring in this case, better to choose a tile, linoleum. That they do not absorb moisture. But the room, as a bathroom or a specially designated room for the boiler, it is not necessary to equip such a way.

methylmethacrylic

Dates can be customized, to carry out repairs quickly. But not everyone knows about, a self-leveling floor to use in this situation. Come to the aid methylmethacrylic coating, able to dry up in a matter of hours. Indicators of elasticity and strength are at an average level. It is possible to arrange on the streets, operate in the winter and cold season at subzero temperatures.

During installation of the cover it can be difficult, associated with a pungent odor. If you do not stock up on appropriate protective equipment, you can generally get poisoned. This scent lasts a few hours, while self-leveling floor is completely dry. After that, no nasty scents in the room will be left. No harm will even air the room, where the works, until it dries.

Two-component

People with the development of technologies tend not to stand still, but always think of something new. One embodiment of the self-leveling floor has properties of elasticity and strength, second - embodiment is a rough base, and the third - in general gives the perfect look the place, to which few people pay attention when. But we want to get all in one, that is, buy a two-component self-leveling floor.

So, eg, There are floor based on epoxy and polyurethane. In addition to the stiffness of the finished version of the base, and it has an inherent plasticity, came from the polyurethane version. They can already distribute and perform the parking places, parking of vehicles, at the train station in the waiting room, etc.. I.e, area becomes much larger.

Gypsum-cement in most cases used in the warehouses, as well as a sub-floor under floor. This is due to their relatively low cost, but excellent leveling qualities base. Even a small layer surface will make a strong and reliable, which will last for at least 30 years old. the main thing, that there has been fully complied with the technology of work and sequence of actions of workers.

When required mixture, withstanding the chemical compound, oils, fats, not only cold, but also hot water, then suitable cement-acrylic version of the device self-leveling floor. There are two components are mixed, as silica filler and Polyacrylate polymer. It is they who give the finished solution of such qualities. Additional features of such a coating - surface roughness, that prevents slipping even on wet floor. Field of use - floors in the pool, bathrooms, showers and similar facilities.

There is also a two-component polyurethane self-leveling floor, The second component confers its properties and characteristics. The most important of them - it's flexibility and good fluidity, eliminating the occurrence of cracks on the surface after drying.

Tech Gadgets

to properly, efficiently and competently perform the device of liquid polymer flooring, should adhere to certain rules and requirements, sequence of work. It will be enough to do everything step by step:

- Complete cleansing of the surface of the foreign object, any dirt and dust. When the work is done on the street - even the asphalt is removed, may have a negative impact in the future on the self-leveling floor.

- Use special mixes, to eliminate unevenness and roughness.

- In certain situations, the surface is primed for self-leveling floor.

- Select the appropriate size container, smeivayutsya wherein all necessary components for a finishing coating or technical floor, and also including optional additives, Components.

- fill. The solution should be poured at the highest point of the room, and then uniformly distributed over the surface. In this case will help the laser level, which will set all parameters. Rolling performed using the needle roller. It will allow it to adjust the layer thickness.

- If desired, the particles may be applied and scenery elements on only flooded with solution.

- If this topcoat, rather than subfloor for laying floor covering, then later 10-12 hours the surface to be lacquered.

To dry any kind of self-leveling floor will be enough days, but can completely dry out after a week. The only exception - methyl methacrylate options, able to dry until ready a day after the installation of.

Self-leveling floor is better not to be used as a leveling screed. In any such irregularities mixture hardens and forms a shell reminder, seals. This will only make worse. In addition, the dismantling of self-leveling floor is very problematic and costly.

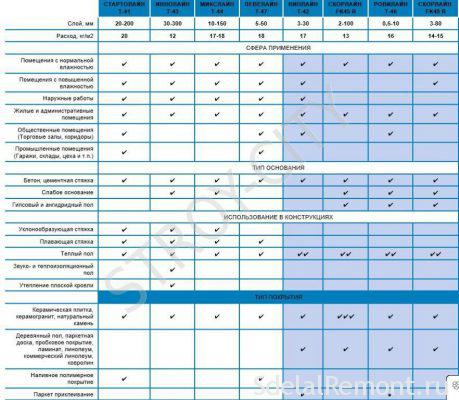

consumption

Very important mix, used in the work of self-leveling floor. It may include various components and additives, facilitating display of certain properties and qualities of the finished solution. When a self-leveling floor basis consumption will depend on various factors, which includes not only the very foundation, but the slope of the floor area. One can not deviate from the minimum solution performance ready for a final coating thickness. These data should be recorded at the lowest point. Often the minimum parameters prescribed mixture directly on the packaging manufacturer.

If finances allow to buy additional bags of ready mix above the amount owed, this should be done. If time does not to purchase the missing amount and pour self-leveling floor, the costs will be much more, bag than once. In short top coat will be ruined and it will have to perform again.

Among mixtures for self-leveling floor basis skorlayn T45 allocated fast drying after installation. Its minimum layer may not be less than 2 mm, and the maximum reach 10 cm. The mixture was applied under any floor covering, including in the device underfloor heating.

For fast setting self-leveling floor Basics skorlayn packed in separate bags 20 kg. If the average thickness select indoors 1 cm, then for each m2 It takes about 13 kg of dry substance. Each kilogram is sufficient to fill 0.35 liters of water. These indicators are optimal and most applicable in the.

When choosing a specific embodiment of the inlet floor should assume, where he will get, as well as any amounts allocated to it. After all, you can make a rough draft for floor covering, and can also act as a finish coating, various decorative elements decorated. It is important to take into account the range of mixtures for device self-leveling floor, which is prepared in strict proportion with all components and water. The most important thing, that in the end will turn out really smooth surface, which is able to serve for several decades.