In the market you can find a huge number of tools for leveling floors, interior decoration. All their old patterns over time begin to leave by the wayside, superseded by new developments, that deserve more attention. The same applies to the self-leveling finishing self-leveling floor, having a large number of positive qualities. The main thing with their device do not violate the technology and strictly follow the instructions from the manufacturer.

dignity

If you run the floor finishing alignment at a high level, it will provide a sufficient number of advantages, which include:

- Confronting external action. They are not afraid temperature changes, vibration, exposure to chemicals during operation or cleaning.

If you use a cleaning agent, a part of which has the abrasive material, You can easily damage the self-leveling floor. To a greater extent this applies to the glossy surface.

- Long life. If you perform all the manual and Technology, observing the requirements of, self-leveling floor finish is able to last for decades. You do not have to do this at no repairs.

- Environmentally friendly. At the time of purchase is not superfluous to require a certificate for production. Only this material is not expected to have any negative impact in the use, after pouring. Isolation of harmful substances is focused only on the drying process.

- executed self-leveling floor It does not burn and does not support this process yourself. The level of fire remains high.

- Appearance. His device in any room will be combined with the interior. The main thing to pick up the correct version of the floor, adding the needed components and additives.

The budget can be saved, if you do the work of their own hands. Installation does not take a lot of time and money. If the room is fairly large in area, it attracted mates.

Composition mixture

As the main component of the finished cement mixes usually acts. This is due to its large number of positive traits and qualities. It is not uncommon use and plaster mixtures.  If you pay attention to the appointment of the mixture used, that they have and the different fractions of aggregates. They can act as ground limestone, quartz sand.

If you pay attention to the appointment of the mixture used, that they have and the different fractions of aggregates. They can act as ground limestone, quartz sand.

We can not forget about builders. Their use in the mixture provides a certain advantage when the casting inlet floor finishing layer. Among the additives included:

- plasticizers.

- substances, improving spreadability on the surface.

- dyes.

- Components to enhance the strength, speed drying of the finished coupler.

Some think that, self-leveling floor screed, or that it is better? It is assumed these basic characteristics. Screed on the basis of sand and cement wins due to the low cost and quick installation. But this gives a rather thick layer, which is not very applicable in rooms with low ceilings, as well as long-term surface drying. All these details allow smooth pouring process of self-leveling floor.

Cooking surface

It is worth noting, the best self-leveling floor leveling will only, if complied fully mount technology, performed properly preparing the floor for pouring self-leveling floor. It is at the initial stage and will be based topcoat.

Used for pouring the foundation must be cleaned of old coatings, however it was not: old screed, tile, a wooden support, etc.. Except there may be only a surface without flaws, which is not necessary to spend forces for dismantling. This also applies to strong tiles attached to the base.

If there are tabs, bugorki, they should be cut with a special tool. Minor cracks on the surface of first embroidered, then primed and sealed with a solution prepared. You can even use self-leveling compounds, which will dry in no time.

Having a door sills, skirting and other elements in the room should be removed, so as not to create obstacles to finish the fill layer.

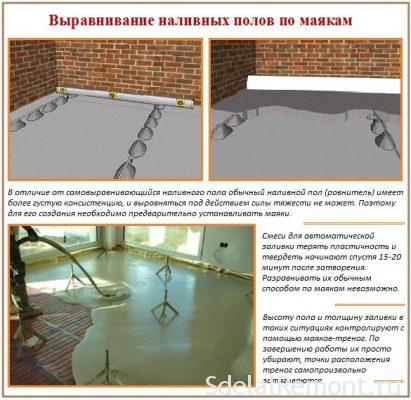

Despite, that mixture have such a property, as the ability to independently to spread over the area in a room, experts nevertheless recommend the use of beacons. In the industry of construction applicable beacons-frames, on which you can put a certain height of the future layer self-leveling floor.

Lighthouses are exposed throughout the area of the room, when they are located at a minimum distance from the back room 50 cm. What is the number - to solve each. Too much would be superfluous when leveling solution. Suffice it to select the step lighthouses 1.5-1.8 m. It is based on the length of the rule, applicable in the. Typically generally selected with a length of about 2.0 m.

Preparing the solution

Based on the properties of the kneaded solution, quickly harden and dry after the addition of water, to this stage should be approached only after all the preparatory activities. To start paying attention to the instructions on the packaging out of the mixture. The recommendations from the manufacturer all the prescribed requirements for the preparation of the solution, proportions, drying time and other subtleties.

To pour the self-leveling self-leveling floor Work must be carried out sequentially and swiftly. There is a self-leveling feature of the mixture is, in a specially prepared container to start a certain amount of water is poured, after which the finished mixture is added.  It is in this sequence will avoid lumps, from which subsequently will be difficult to get rid, time-consuming. Here time here plays essential, depart from it in any case impossible.

It is in this sequence will avoid lumps, from which subsequently will be difficult to get rid, time-consuming. Here time here plays essential, depart from it in any case impossible.

The process consists of mixing a solution of two phases. After obtaining a homogeneous mass, should stop for a few minutes, then repeat the stirring. there are cases, it is necessary to give a solution of certain qualities. To this was added substances and additives. Their addition should be repeated only for stirring the solution.

floor leveling stages include mixing a solution of, as its quality can affect the final surface. If you add more water, than it is necessary and recommended, after drying, strength and durability will not quite worthy.

The process of filling floor includes kneading a specific amount of solution. It should last for minutes 30-40 work. Otherwise, it will start to harden prematurely and lose its quality, primarily on their own strength and ability to be distributed across the surface. If you need a certain amount of, Assistants are available in the right quantity, kneading the mixture, and the water must occur in the appropriate volume of the container. No breaks should not be allowed, if you want to get a smooth and level surface.

The process of filling

To align the floor with their hands step by step instructions must be observed in full and on time.  After mixing the solution, we must immediately begin to fill. To this end poured from the container on the basis of ready mix, then no harm will razravnyat using a rule. It is not always the solution will be able to spill out evenly throughout the room space. Even the corners are still intact, where it is necessary to perform a fill.

After mixing the solution, we must immediately begin to fill. To this end poured from the container on the basis of ready mix, then no harm will razravnyat using a rule. It is not always the solution will be able to spill out evenly throughout the room space. Even the corners are still intact, where it is necessary to perform a fill.

The beginning of all work carried out on the far corner of the room. Subsequently the entire solution is distributed by means of a rule to the input. No harm will be used at the same time assistants, hired to work. So sex increases pouring guarantee in the whole house while preserving its qualities.

There's even a question in order, whether it is possible to re-fill self-leveling floor. It should not do it for the reason, then what will poor-quality surface. If already perform a second layer on the floor of the inlet filler floor, then the base to prepare, removed all extraneous elements, applied primer layer.

self-leveling floor or dry screed, it is better to opt for a high-quality surface finishing layer. With the help of ties is impossible to obtain a smooth surface, and it does not always get a perfectly flat screed. Completion of the floor of the finished casting solution mixtures can only be painted or decorate decorative elements. layer minor, that over time it allows for simple repairs using the recasting. The distance between the floor and ceiling with virtually no change.  So instead of a floor screed is best to arrange a finishing self-leveling floor, It has a huge number of positive qualities, that brings it to market leadership.

So instead of a floor screed is best to arrange a finishing self-leveling floor, It has a huge number of positive qualities, that brings it to market leadership.

But all will count, that allows a topcoat to receive a thin layer of the floor. But is it possible to align the floor self-leveling floor? Doing this can and should be, but are used in the self-leveling mixture to reduce costs. They can simultaneously become a topcoat.

Please note

To align the floor with his hands self-leveling floor, should follow certain tips from the experts, with vast experience in this area.

- For the application of the finishing layer can not use such a base, as a reinforced concrete slab or monobeton. Traction is minimal. Due to the thin layer of solution, it over time begins to break away. Will have to carry out all the work again.

- To know, exactly how to fill self-leveling floor, It is qualitatively prepare the mixture and dilute it with water. The consistency of the mortar should resemble a thick cream. Easy control is carried consistency by adding water or the dry mixture. All depends on the state of the solution after mixing. About any "liquid milk" speech should not be. Here only get a large number of cracks after drying.

- Applying the solution should be performed only after, as a completely dry substrate after cleaning, if screed. The same applies to the primer. It should be dry before applying the fill.

- Manual alignment is performed in solution anyway. For this purpose the needle roller. If the layer is less than 2 mm, that everything is done carefully with a spatula.

- If performed topcoat inlet floor, the base should be primed at least 2 fold. All will depend on the moisture level and the desired level of adhesion.

During the works should be maintained not only a certain temperature in the room, but also the level of humidity. These indicators will play a role in the manifestation of the properties and quality of the final solution.