Neither technology is not necessary on the spot, and is constantly being improved. You can not ignore the construction area, and in particular - self-leveling floors, who constantly bring new options for execution. Popularity spread not only in old buildings during renovation, but also in new buildings, when it is necessary to align the slabs. But few people know about the time frame drying self-leveling floor in certain circumstances and depending on the specific type of. Much will depend on the used floor covering.

Effect on drying

In each case, different drying time self-leveling floor. The reason for all of this - a huge number of factors, among which the most common:

- Layer thickness and its.

- the temperature and the humidity in the room, where the installation is carried out self-leveling floor.

- The number of layers, which are applied to the base.

- The presence of certain additives in the composition of the finished solution. An important then their characteristics.

- Manufacturers mixture to fill the base of.

- The type of coating.

In this case they can have optimum average timeframe, and sometimes necessary to wait a little longer. Everything will depend on the operating topcoat self-leveling floor, indoor conditions and other factors.

Grasps solution may already one hour after pouring, but it is able to dry out after a minimum 6-8 hours. These data are focused on the most popular mixture, most applicable in the.

The conditions for drying

It is important to comply with certain requirements, which are necessary, to the drying process took place in favorable conditions,. Himself ready solution of the mixture should be as evenly distributed across the area of the premises.  Indicators temperature within the room should remain within +22-25 degrees, without creating surges.

Indicators temperature within the room should remain within +22-25 degrees, without creating surges.

If you use a special film, it will be able to protect the surface from ultraviolet rays hit. better course, when the sun does not get into the room, which is made self-leveling floor. From this will also depend, as drying self-leveling floor. Must be supported and the optimal level of humidity in the facility - within 60-65%.

Best of all the room very close to the drying time. You can protect it from the appearance of drafts, wind and other conditions of the environment fluctuations. The same applies to the temperature, which must be kept at the same level. It makes no sense to use a variety of equipment to increase the temperature and rapid drying. It can only hurt, surface will dry unevenly.

If each of these items will be met from the beginning to the end, the drying uniformity is guaranteed. Thus it is necessary to pay attention to the drying time, which is usually specified by the manufacturer on the finished mortar to prepare a solution for self-leveling floor.

When, such as moisture will be more, than necessary, then dry the floor can, but it will take some more time, than standard.

Setting and complete drying

Not always people can distinguish these two very important concepts, as the setting speed and fill the drying time. In the first case, the surface will be easy to move around, and the second carry decoration and if necessary perform decking flooring. Preliminary setting is achieved after a few hours. But it should be remembered, much will depend on the mixture used to fill the inlet floor. Full moisture withdrawal from the composition of the mixture is achieved at a mean 4-7 days after the installation work. Everything will depend on, which layer is formed.

Warm floor It can be switched on only in the event, when the surface is completely dry. the whole "pie" up to this point may be damaged and cracked. It is better not to risk, and wait the extra time.

Taken separately floor also makes demands to humidity filler layer. You have to understand, as dry bulk floor under the laminate, since such a material has the ability to absorb moisture. If the surface remains even slightly damp, the laminate elements will be deformed due to high humidity. It hurts all the material, which have perestilat, spend the extra money and effort to work.

options coatings

It is worth noting, that slurries require the artist more time waiting to dry completely.  But their application is aimed at garages, industry objects, outbuildings. Complete drying self-leveling floor is carried out only after at least a week after the installation.

But their application is aimed at garages, industry objects, outbuildings. Complete drying self-leveling floor is carried out only after at least a week after the installation.

High quality and enormous strength polyurethane coatings characterized by. After pouring on it is possible to move later 14-18 hours. Fully it can dry out only after two days. Time will vary, including the thickness of the screed layer.

Slightly more drying epoxy Self-leveling floors. At least five days will have to wait until the complete drying of the surface. In this embodiment the finished foundation able to withstand various types of external mechanical influences.

The drying process different polymerization mixtures are called. It should select other variants mixtures, which will have a different deadline own polymerization.

- The polymeric surface on an industrial scale typically dries within 2-6 day. On timeframe will affect available in the additive and impurities.

- gypsum (anhydrite). One has only to remember here, that this surface is very afraid of excess moisture in the room. That was enough foot traffic to the base self-leveling floor, it will be enough time for two days to complete drying. To further put the furniture - expect at least 10 days. Previously place all possible, but then it will suffer a surface finishing layer.

- quick-drying surface. When a small period in the drying surface 2-5 hours, All specifications are at a very high level.

Each manufacturer specifies in their mixtures estimated time to complete the polymerization of compounds. This can be followed, but that has to be confident in the final result - to be added 10-12 hours. Only after that you can easily carry out laying flooring.

Drying 3d floor

Should know about, how many floors dry after casting, made in 3d format.  Here in many respects it depends on the layer, used for planarizing. It does not play a small value and pattern, parameters of its application. By paper or picture can be applied immediately and wait ready solution it dries. If the pattern is made with paint, it bides its time for drying, and only then executed laying self-leveling floor.

Here in many respects it depends on the layer, used for planarizing. It does not play a small value and pattern, parameters of its application. By paper or picture can be applied immediately and wait ready solution it dries. If the pattern is made with paint, it bides its time for drying, and only then executed laying self-leveling floor.

Each individual polymer coating, as mentioned earlier, It has its own timeline until dry. These are the ones to be followed in determining the time, as dry drenched floors. In addition to this is added a drying glossy surface, at the base of which protrudes lacquer substance. true, Varnish is not always used when dealing with 3floors, d.

Conventional leveling floors dry much less, what made 3d floor in the volume. The minimum term is usually a week. quick mixture used to accelerate.

Comparison of different solutions

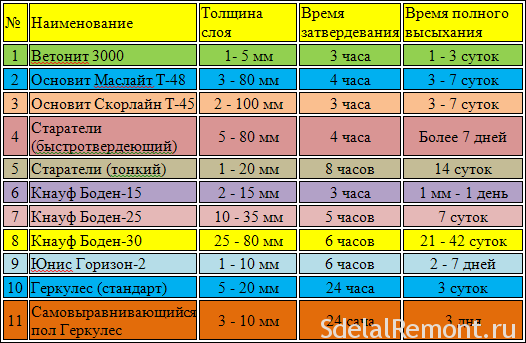

If there is no understanding of, which fills the floor dries much, you should contact the manufacturer. Each package is a mixture of information on averages surface drying until ready. It is impossible to categorically look at the structure and navigate through it. Manufacturer uses during the development of the various mixtures and mixture components, their quality and quantity. There is an exemplary table of parameters, where the relevant information is available.

All this shows us only what, that the spread of time, as self-leveling floor dries very extensive. The most nimble in this direction leveling floors - bystrotverdeyushchie (eg, «Guardians»).

In addition, watch the video on bulk floors.