Arrange quality and durable flooring currently is not difficult. This is achieved due to the presence of modern building technologies. Acts as the main filling inlet floor. This is due to its large number of advantages, as well as an excellent result. Moreover, it can be used not only as a finish coating, but the draft of the laminate for subsequent laying, parquet, tiles. The most important thing - to strictly follow technology devices, to obtain high-quality base.

Types of self-leveling floor

As I mentioned above, leveling floors may have a coarse structure and be rough draft. But there is a finishing coat - finishing. It is smooth, light and is used for subsequent painting or decorative flooring elements. If at the same time to connect them into one and perform consistently, the floor is the perfect option. All deficiencies are eliminated, is added and the beauty.

Floor stand composition:

- gypsum.

- cement.

- epoxy.

- polyurethane.

- methyl methacrylate.

- combined.

Each of these options self-leveling floor has its own qualities, distinguish it from other. Of particular interest is the last kind of, which can include components of different mixtures. This is necessary for a particular room, depending on the preferences and requirements.

Best floor for pouring

There are certain criteria, that will focus on the choice of self-leveling floor. It is very important appointment premises, where the work will be carried out. If it comes to an apartment or private house, then choose the best polyurethane Self-leveling floors. They also act as an alignment surface, smoothing of irregularities, as well as to give room design notes of beauty. It is a kind of decorative covering.

When the casting polymer floors require minimal amount of knowledge in a given direction, as well as physical labor. Handyman may carry out installation without difficulties. Slightly more skill will have to make at the device 3d sexes, which differ elegance and attractiveness. If desired, the result will be easy for beginners, trying and seeking such knowledge.

Any outcome will depend on the initial work, of preparations. If someone thinks, that all the errors in the subfloor can be subsequently hidden, what exactly is wrong. conversely, they all come out and be visible to everyone.

In the absence of professional knowledge, a job best done by a specific floor covering, to cover all the possible shortcomings. Otherwise, not to waste their strength and resources, once, you can seek help from the experts, who will perform all types of work from start to finish.

Decorative floors can be of the following categories:

- monochrome;

- With an image;

- 3d picture;

- frosted;

- glossy.

Looking at reviews, You can make a definite conclusion, that if you pour the floor on their own and at the same time choose a glossy finish, with the scratches may appear for a short time, which detracts from the appearance. But much will depend on the technology of the work, as well as mixtures of the acquired. Each manufacturer even consistency of the final solution obtained by different.

choice of instruments

The equipment used in the operation will depend on the particular type self-leveling floor. Greater number will have to be found in the device 3d floor. In general, in addition to the standard list hammer, bead, brush, a certain volume of containers, It should include drill with paddle (mixer), special shoes for moving the wet solution, aeration roller, damper tape, primer, etc.. A specific list will depend on the situation. By carrying out the work must be approached individually.

hammer, bead, brush, a certain volume of containers, It should include drill with paddle (mixer), special shoes for moving the wet solution, aeration roller, damper tape, primer, etc.. A specific list will depend on the situation. By carrying out the work must be approached individually.

Do not be amiss to select and ready-mix for subsequent mixing. On its quality and the quality of the final grade will depend on, strength.

Composition mixture

Virtually all mixtures include certain components:

- fillers. Some materials - sand, lime chips. Depending on the composition will depend on the fraction. If the base layer is arranged screed - 1.2 mm, a topcoat having a fraction component to 0.5 mm.

- supplements. They give a solution to the future better flow to the base, plastic, increase the degree of adhesion, What is particularly important for concrete floors.

- binders. Here, the main component - cement. He gives a mixture of gray shade. Also it can be used gypsum (beige shade). Foreign manufacturers used as the binder polymers.

If you wish to receive a particular floor color, the mixtures are selected from dyes. To mix all the ingredients are well connected to each other during solidification, use microfibre. They also help to reduce the appearance of cracks to zero.

For subfloor mixture used in gypsum-based. The cement foundation finds its use in kitchens, toilets, Bathrooms. In the latter case we are talking about high humidity, permanent hygienic care, with which almost can not handle plaster.

When the device underfloor heating It needs a ready solution, having increased elasticity. bystrotverdeyushchie purchased mixture to speed.

Options for self-leveling floor

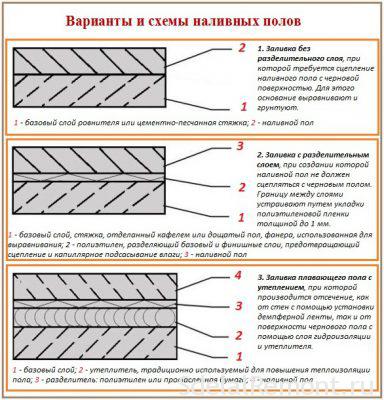

Before, how to pour self-leveling floor with their hands, select it for specific variant. It is about the thickness of the layer, which is required in the room. Also play a role material and the degree of exposure to external.

- Final coating with a small thickness to 2-3 mm. Screed can only be carried out on this basis, which fully complies with the technical regulations and has a flat surface. In this case the solution must adhere well to the surface, on which poured. To increased adhesion to base, Recently, should be treated with a primer composition.

Before the primer also perfectly suited for surface grinding work, to make the surface roughness. These measures will also improve the adhesion.

Before the primer also perfectly suited for surface grinding work, to make the surface roughness. These measures will also improve the adhesion. - Floor, severed by a separating layer on the base. Often used on wooden base. The same applies to the screed, having a thickness 10-20 mm. Bit worth a stop on the separation layer. Here, in his capacity as advocates oilpaper, roofed under self-leveling floor overlapped sheet on the sheet. To concrete or cement is not clinging to topcoat, between greasy waterproofing impregnation. Paul will not deteriorate due to the fact, that wood is a "move" over time. Cement and thus a will not pick up moisture from the inlet floor, because of which the latter can acquire crumble and negative qualities (shell). In this way, by the way, made 3d floor. They act as a separator banners with pictures, any other image, sticker.

- floating type. It is used when laying the floor covering need (laminate, linoleum, parquet). After said material over time may vary, change its quality and size of the temperature difference, because of the different levels of humidity in the room. The thickness of the floating floor is taken within 25 mm. In this case, self-leveling floor will solidify or acquire themselves any defects. As the separation layer serves polyethylene (alternative - parchment, waterproofing rolls).

But that's not the whole list of schemes, which can be poured self-leveling floor. Everything will depend on the specific conditions and circumstances, under which the installation of. But, despite all the variety of options, principle of the device in each of them one.

Stages substrate preparation

Preparation for subsequent pouring self-leveling floor plays essential. On the quality of work will depend on the quality of the final version. To get started is to decide on the basis, with its irregularities and problems.

With large height differences or protrusions arranged separately, they are best removed with a hammer. Otherwise it is necessary to spend a lot of money on the mixture for a solution.

Checks screed filling strength under floor. any areas, which exfoliate and crumbled, They should be eliminated and removed. Each change will manifest itself in the future.  All portions of the surface deformation is primed and lubricated mixture screed. Enough to buy it ready-made options. Drying is very fast. Also eliminates any cracks, chipped, where can get fill.

All portions of the surface deformation is primed and lubricated mixture screed. Enough to buy it ready-made options. Drying is very fast. Also eliminates any cracks, chipped, where can get fill.

In the process of drying the prepared solution it may deform due to changes in temperature, and as a result little shrinkage. To avoid this, the perimeter of the wall mounted damper tape. It softens any possible distortion. Subsequently, after drying, self-leveling floor is trimmed.

The room temperature should be minimum 15 degrees. This is the optimal temperature for. Windows and doors required to be closed. Especially avoid drafts. Low temperatures promote the slow reaction in the kneaded mixture. This should be avoided. The same applies to higher temperatures.

Humidity is very important foundation, which should not exceed 4%. When the humidity is difficult to fight, You have to use a layer or even several waterproofing. To increase the adhesion of the self-leveling floor with a concrete screed, use primer. If you do not, self-leveling floor will acquire various defects. Primer is applied with a roller. After that, you should wait a day to dry.

Features wooden base

Some wonder about, how to pour self-leveling floor on a wooden base in a private house. Here the main thing to observe a few important aspects, without which a good result is not obtained:

- The maximum level of moisture content of wood - 10%.

- Absence of varnish or paint on the basis of.

It is removed in the presence sander or other possible properties. Subsequently, the surface is ground using sandpaper. This procedure contributes to the appearance of furrows, increase the degree of coupling self-leveling floor.

It is removed in the presence sander or other possible properties. Subsequently, the surface is ground using sandpaper. This procedure contributes to the appearance of furrows, increase the degree of coupling self-leveling floor. - After removal of the dust and dirt, the surface is wiped with a damp cloth.

Should pay attention, that even experts can not give an absolute guarantee, that over time, self-leveling floor is not cracked due to changes in the parameters of wood. There is a risk of. In this case it is best to use not in direct contact with wood, and apply the separating layers, selecting a suitable option from possible schemes. Screed thickness also play a role.

Pouring the base layer

Not difficult to find out about, independently pour self-leveling floor, people, aspiring to this. All skills can be purchased in a short time and do the work with his own hands, not to spend money on professionals.

The first - the base layer. Using a bar of metal, spilled on the floor solution is leveled across the floor space. Special tool then performs a squeegee, having a gap, Capable of handling up to the required thickness of the self-leveling floor.  Under the battery or in other places, where it is difficult to get, can be used roller.

Under the battery or in other places, where it is difficult to get, can be used roller.

From the mixture must be removed when mixing bubbles formed. This helps aeration roller. He has special thorns, facilitating rapid removal. spines will depend on the length of the screed itself.

Since the finished solution should be evenly distributed, then we have to move independently around the room. To accomplish this, you must buy kraskostupy, have spikes on the soles. If the room is large in size, then fill to better fulfill several people at the same time and in a staggered manner.

finishing layer

But how to pour self-leveling floor afterwards? It is important to wait a few days to complete drying of the base layer. Despite the different thicknesses of the base layers and the finishing, techniques completely analogous to the device of.

After drying and finishing layer, the surface is covered with polyurethane varnish, Allows you to save shine, but at the same time to increase the service life of the filling of the finished floor. In each case it is important to maintain the temperature at a certain level in the room to dry surface. floor moisturizing at the same time no one ever carries.

Future floor surface can be given a non-slip effect, using a very simple way - sprinkle a little washed sand. Besides the removal of air bubbles is carried aeration roller. All of the crater, which will appear from the disposal of air and will not give slide.

Everyone will be able to understand the technology of self-leveling floor, regardless of the conditions and grounds, which he poured. It is important to plan all actions, to perform the work at one time, for a predetermined time.