Self-leveling floor is gaining popularity not only in industry, but also for the repair of premises. This indicates, that this floor device technology is available to everyone for the development of. Therefore, that not only the builder, but also a beginner needs to know about, that will affect the durability of its minimum and maximum thickness. In no case can not be arbitrary, as it is influenced by certain factors.

From what thickness depends

there are options, from which the full thickness of the future will depend layer self-leveling floor:

- Alignment the subfloor, its level, height.

- Mechanical load during operation. Very important here voltage coefficient: vibration, surface durability, external mechanical action, pounding.

- Mountable maximum washcoat. However, he must comply with the binder material.

If the layer of self-leveling floor will be less than the desired value, does not reach the optimal setting, and then not be able to last for a long time. Operational characteristics push it and immediately begin to emerge defects and inaccuracies. In this case, a very large filling layer does not give a positive result over, but only will be spent extra money from the budget.

types of coatings

There are many blends, applied to the device self-leveling floor. At the same time they have very different parameters thickness, which are necessary for quality flooring coatings. Among them are:

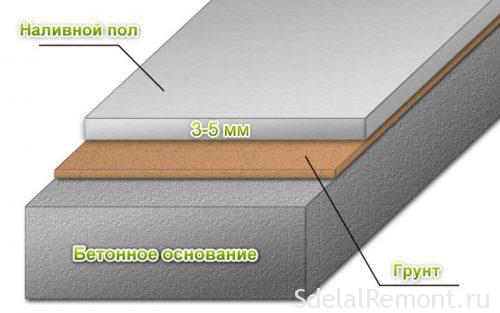

- Thin-film. Layer wherein the thickness does not exceed 5 mm. The main function of the floor - base protection from environmental factors. Its amount will depend on the type of mixture, producer, received quality. If you add some more, make higher consistency, the strength increase slightly.

- Samoniveliruющiesя. Such a layer can reach adjustment 20 mm. It has excellent anti-static characteristics, and easily cope with numerous mechanical loads.

- highly filled. It can not be stacked layer less 20 mm. The composition of such mixtures are the most common quartz sand, magnesite, expanded clay, etc.. This slightly reduces the cost of the finished mixture for dilution.

Thickness depending on the composition

Depending on the material, which is used for mounting different thickness and surface. So before, how to obtain such a mixture, should examine its characteristics, Purpose and properties.

- The polymer coating has the optimal values of thickness 40 mm. But never one manufacturer does not recommend self-leveling floor from such a mixture is less than 25 mm. Reduction can occur only in the event of a subsequent surface staining. But the reduction should not be more 0.3 mm.

- methyl methacrylate. As the concrete surface serves as the basis or steel for him. Average thickness 6 mm can withstand load, reaching by weight 15 tonnes.

The optimum thickness of the inlet floor - The cement-polymer composition is used in self-leveling floor device on wood or ceramics. Adhesion to the surface of his great, and the thickness may be up to 50 mm without loss of quality and functions.

- Low-temperature rooms. The basis of such resin mixtures methylmethacrylic, including also the components against frost. The maximum thickness is in any case should not exceed 7 mm.

- Acrylic cement. This is a classic option for filling self-leveling floor. The average values are within the thickness of 10-20 mm. After installation, the surface can withstand the mechanical loads, and easily resists various chemicals.

If the room is a large load, the layer should not be less than 10 mm. From this it should be used in selecting a particular embodiment for a mixture of.

In addition, there are a mixture of damp room. Also the presence of water permanent floor surface can be continuously flushed with water. No seams in acrylic cement mixture did not form, while it remains hygienic, does not require alignment of the surface to fill.

fill rules

During the execution of pouring self-leveling floor should adhere to certain rules, without which it is impossible to manage any professional in this field, any newcomer. This will help avoid problems during installation, during operation surface. Every mistake takes not only time and effort, but also a lot of money.

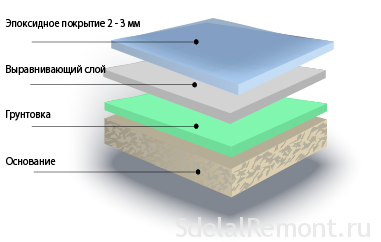

Before pouring polyurethane self-leveling floor You should allow at least 12 hours after the preparatory activities.  The primer should be thoroughly dry. In contrast, the epoxy resins require longer drying foundation - at least 18 hours.

The primer should be thoroughly dry. In contrast, the epoxy resins require longer drying foundation - at least 18 hours.

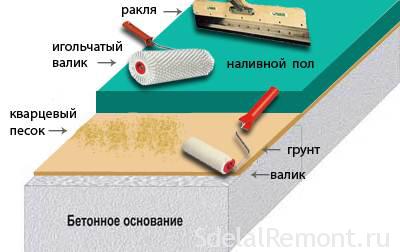

The finished solution is practically very few people are ready to fight in the same capacity. Thus it is necessary to take into account the proportion of water addition, not to receive a different mixture in one room. Properties and strength characteristics they differ, and the clutch will not be uniform. After that, as practiced by pouring self-leveling floor parts, the whole solution has to be distributed over the surface in the room. To do this, use the metal bar. If it is difficult to enroll in certain places, You can apply the roller.

During the mixing of the solution are formed in it bubbles. They are also in the casting room. To use them to get rid of the aeration roller. Depending on, what will be the thickness of the filling self-leveling floor, different and the length of the spikes on the roller.

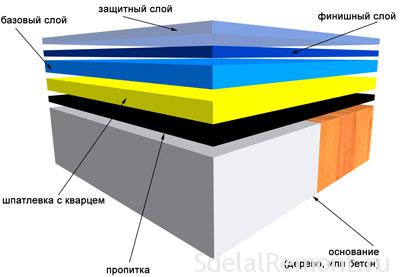

Initially, the base layer is poured, but only after a certain time - topcoat. The principle of the technology and devices they have is no different. The main difference - the thickness of the self-leveling floor, that the latter is only a few millimeters. So that after installation the floor surface remains shiny and can serve for a long time, it is coated with a special varnish.

casting technology self-leveling floor with their hands is very simple and will be clear to a novice builder. It is important to comply with all requirements and pay attention to the nuances of. This is useful not only for the individual preparation of, and for supervising the team of specialists.

thin technology

Before, how to make self-leveling floor, It should stay on its concrete embodiment. In this case, everyone should understand, that every millimeter is essential. Especially in this direction have advanced polymer coating, where even 1-2 mm will be enough, to withstand a certain load on the surface. true, not everyone can make such qualitative thin layer. The screed will be even minor recesses, where the solution comes to self-leveling floor.

In this case, it is important to be aware of, as do self-leveling floors. After a thin layer of finishing coating is typical for.  When he has, then there will be some intermediate. That is, the base layer and allows smooth unevenness or concrete screed, very foundation. These mixtures also are not expensive due to the peculiar structure: gypsum, sand, Cement, plasticizers. Polymers are almost completely absent, and if it is available in a small size, then only the surface to impart fortress.

When he has, then there will be some intermediate. That is, the base layer and allows smooth unevenness or concrete screed, very foundation. These mixtures also are not expensive due to the peculiar structure: gypsum, sand, Cement, plasticizers. Polymers are almost completely absent, and if it is available in a small size, then only the surface to impart fortress.

Maximum thickness of self-leveling floor, rather the base layer, can reach 80 mm. If at the same time in the mixture and the polymers were, their final price would have been beyond the clouds. If you have to make even greater screed, it is best to apply the fill of the other components, such as expanded, and only then proceed further. Cheapness also contributes to their replacement by semi-dry screed. The surface becomes very smooth and can be used under any floor covering. Base layers can be topcoated, as very easily abraded and have less strength in operation.

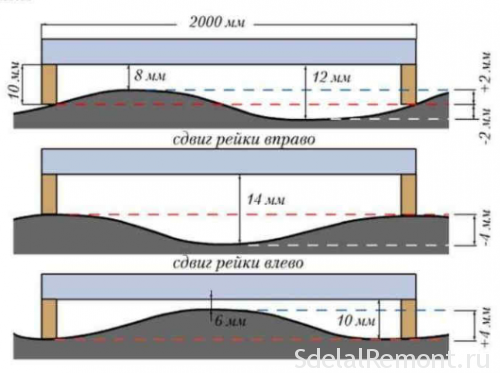

The work can be carried out using mixtures of fast. Particular attention is paid to lighthouses and their placement. If it does not control, then the parameters of the manufacturer's thickness will be broken.

Optimum layer

Despite the high cost of self-leveling floors of polymers, are provided for a minimum thickness. Optimal formulations sometimes extend to a few millimeters, such as polyurethane compositions. On top of this structure can be applied even with Colorants, not more than a thickness 0.3 mm. Even giving gloss and surface beauty does not take a lot of space on the entire surface.

Nobody does such floors for more than five millimeters, since all the characteristics still remain at the same level. Only the money goes down the drain. These parameters are typical for the thickness epoxy compounds. true, if you want to paint a surface, the layer should be made large due to the great brittleness of epoxide.

Quickly dry methyl methacrylate compounds, and wherein the layer can be carried out in 1 mm. This height will be enough for the minimum load. When there is a cement-based mixture, the layer will be optimal in 8 mm.

heavy loads

Specialists can answer the, self-leveling floor thickness which can be filled. However, they all repeat, that self-leveling floor screed with a large thickness should not be used. In this case, it is best to use a special mixture, able to align elevation changes. Quality at the same time in the mixture will be different depending on the manufacturer. To this should be taken carefully.  Such compositions can not be used as a finish coating due to small strength characteristics.

Such compositions can not be used as a finish coating due to small strength characteristics.

Very much filler layer solution floor, exceeding the optimum performance, It will be a long time to freeze. During this time, a problem creating favorable climatic conditions for drying: humidity in the room, temperature, no drafts, etc..

If no thick layer can not be avoided, it is necessary to perform the work in installments: Pour one layer, and after drying start to the second.

Thickness at low temperatures

If there is the desire to perform self-leveling floor with his hands step by step guide will help accomplish this. But it is important to look at individual cases of work, such as, in the case of constant low temperatures. It is important to choose the appropriate option for the mixture, based methylmethacrylate resin. There is in them, and special components, promoting anti-frost. To self-leveling floor is actively opposed to low temperatures, its thickness should be within 5-7 mm, not less. Cold rooms - this is a great option for devices such floor.

Saving Appliances

Many people know about, how to make a self-leveling floors with their own hands, but not everyone can boast the ability to save a solution while working. There may be cases, even when the ground under the base layer is not entirely curved, you can work grinding machine. In this case, the irregularities are smoothed, and on the surface will be less then, which require fewer coats.

Should eliminate every crack and pothole, as it can to get the composition of the finished solution is self-leveling floor. instead of leveling, everything goes into the void.

The primer can not buy, and do it yourself. To this mixture was taken for self-leveling floor and diluted to the point, to remind the paint consistency. After applying it to the surface roller floor, quite a few hours to dry, then you can begin to implement the "pie" self-leveling floor.

You can save on the base layer. To this is added to the mixture sifted sand and very fine. After drying this layer it is further aligned pure composition for the base layer (enough and one millimeter). The paper also takes an active part roller or rule. In each case it is necessary to comply with the technology and individual approach.

In this way, the height of self-leveling floor will be fully depend on the particular premises, its parameters, as well as the environment conditions. Maximum casting thickness of the filling the floor must not exceed the specified parameters from the manufacturers. Not always the height will give excellent performance. When pitting with Polymer Flooring, higher layer only take money from the pocket, and all the characteristics and the quality will remain the same.