Any subfloor for subsequent finishing floor covering should be carefully align. For this there is a lot of variants, among which it is worth paying attention to laying plywood. But here it is necessary to take maximum measures for the perfect base for. Otherwise, you may experience negative symptoms - creaking, covering destruction, deformation, etc.. In addition, the use of plywood is not consuming high finance, and the installation process takes a shorter period, in comparison to other options.

types of alignment

plywood laying on the floor may be different. If it comes to a wooden base, it will most often be enough to fasten sheets of material to the old base.  In this case, the very foundation and should be prepared to give it the maximum horizontal level. The same applies to the floorboard, that no harm will all be dismantled for packing.

In this case, the very foundation and should be prepared to give it the maximum horizontal level. The same applies to the floorboard, that no harm will all be dismantled for packing.

Is selected and certain plywood size for repair. It usually should not be less than 1 cm. Some of the used lag, after which the stacking devices produce veneer sheets. In the following various possible to produce flooring flooring - tiles, linoleum, laminate, etc..

The choice of plywood

Depending on the acquired flooring and veneer should be chosen embodiment for laying on the subfloor. For linoleum carpeting is sufficiently small sheet thickness. True and align major defects are unlikely to succeed.

about 10 mm thicker veneers to be, have staged under the laminate and parquet. In residential areas are mainly used such material grade, FK FSF or any. In the former case it does not contain any harmful substances (eg, phenol), which may adversely affect human health and others during operation. According to the level of water resistance refers to the average, but it is able to withstand even a substantial external mechanical influences.

The FSF based plywood grade - phenol-formaldehyde resin. This immediately suggests toxicity material. In this case, much higher water resistance performance, and a wear level using.

In DIY stores presented plywood grades, which only emit 4:

- 1-grade. It refers to the number of best quality material, which has no defects, other than minor surface cracks and deformation. Sometimes they are not even visible. Him, of course, recommend to align each subfloor, but the cost will be very high.

- 2-grade. Of the defects can be found even glue, timber insert, and dents.

- 3-grade. Also traces on the surface of wormholes noticeable slight swirls parameters.

- 4-grade. His few uses because of very poor quality. During the processing and creation of materials exhibit all the negative qualities, defects, inherent plywood. This variety can not be used at all.

Ideal for floor arrangement and creating a flat surface - Class II. It has all the advantages and qualities, which are necessary in the work and during the operation.

Thus it is necessary to pay attention, that plywood can be ground on one side, on both sides, or be general unground. Each of these options are also immediately reflected in the cost and scope of the.

Benefits

With the help of plywood can be as fast as possible to create a flat floor surface, which subsequently is used for flooring or floor covering for processing. But the merits should also include other features of each sheet used in the work:

- Despite the large size sheets of plywood, they are very easy to transport.

- Finished ground is not only durable, but also safe to use.

- Each can independently carry out installation of plywood subfloor.

- Of all the possible odor materials may be mentioned only the fragrance of wood. But if you do the flooring floor covering, it will be the complete absence of any foreign odors.

- Laying plywood floor can be carried out even in environments with high humidity levels.

- During execution mounting sheet material it is very easy to cut, customized for the required dimensions, and covering any kind of protective means. At the same time it does not remain almost no construction waste.

- Sheets kind of very hard, but they can be bent to the desired setting.

When the device floor of plywood, it acquires further heat insulating qualities. Heat to a lesser extent leaves the premises. Furthermore draft of plywood on wooden base, and it is used as a finish coating. It all depends on the level of grinding and selected varieties.

Substrate Quality

Any basis for further alignment must be carefully prepared for. The room itself must have a valid level of humidity. To do this, made all the necessary measurements. Most often, this also applies to concrete floors.

To check the moisture level of the concrete floor should be three days put on it a piece of polyethylene film. The edges of her at the same time should be carefully pressed against the base. After this period the film is checked. If there is condensation inside, the humidity level is high.

To reduce the humidity level in the room and grounds, It should cover it with special means, and antiseptics. Subsequently, it will contribute to the fight against mildew or fungi. For rough leveling the cheapest option - 4th grade plywood.

Particular attention is paid to the wooden base floor. All the available space around the perimeter of the plinth should be removed. You can face the floor hanging out, creaks.  To do this, initially learn, where it's all happening. Most of all - it's a bad fixation of wooden planks. Nails with operating bumped over time. Getting rid of this problem is very simple - the duplication of nails on the site of the wooden floor, as well as additional scrolling them with screws. Each lag, boards must be fixed. Conventional screws length in this case - 50-100 mm. the main thing, that they did not reach the ceiling panels when available.

To do this, initially learn, where it's all happening. Most of all - it's a bad fixation of wooden planks. Nails with operating bumped over time. Getting rid of this problem is very simple - the duplication of nails on the site of the wooden floor, as well as additional scrolling them with screws. Each lag, boards must be fixed. Conventional screws length in this case - 50-100 mm. the main thing, that they did not reach the ceiling panels when available.

If there are irregularities on the wooden floor, îíè stesыvayutsya plane. This will allow in the future to get rid of the appearance of the mounds on the sheet of plywood.

Alignment with the grooves

You may encounter when working with significant recesses. This is due to the constant presence in a given place of massive objects or constant load. For this sequence of actions provided, which includes the following items:

- We define cavities with a long level.

- In designated locations at a distance 20 cm apart are screwed screws. They will be a kind of beacon. For precise calculation of cap rate level applied.

- Data on the screws and will be laying sheets of plywood. But even in this case it is possible deflection plates in the recesses.

- To get rid of the negativity, void under the sheets filled with fine sawdust, are mixed with PVA glue. Plywood coated with PVA glue and on the reverse side. Complete drying adhesive typically 5-7 days. This period must be maintained until the next work.

In general, to determine the height differences based on gender should be used not only water, but also laser level. This will get the most accurate results.

Scheme

there is 4 the basic scheme, Guided by which you can make stacking of plywood on the floor with their hands:

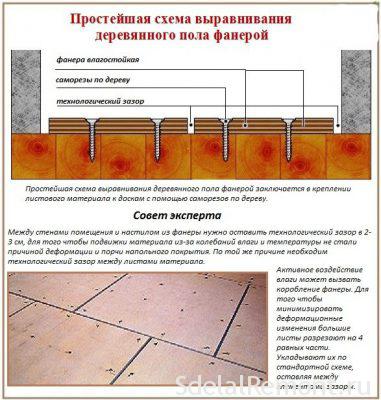

- Without lag device. No additional boards does not apply. This option can be called a very simple in terms of installation. Of each wall must be held in the indentation 20 mm. The distance between the plywood sheets should be about 5 mm. The variant floor leveling without lag in the two layers of plywood. In this case, to make installation on the principle of stacking bricks, ie in a staggered manner. Since the installation is carried out on the plywood boards curved bumps, the fixing is carried out to the highest point and evenly over the entire surface.

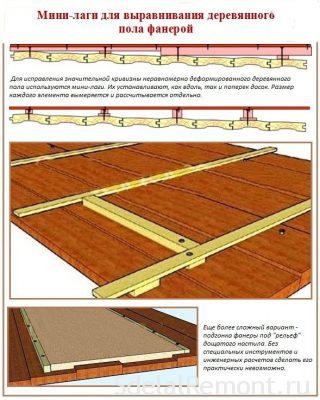

- Replacing the Mini-lag. It allowed of plywood aligning apparatus in the case, when the elevation changes make up 80 mm. installation process is fairly complicated and involves fixing rails, and wooden planks. With their help, we performed a single network supports for future sheets. It is important in this case to produce accurate estimates, to the task set was performed with maximum efficiency. Each element has its height and size, which is also calculated in the process of preparing.

- Fixing lag longitudinal cross-boards. Of each wall joists are attached to the base at a distance 30 mm. In the following will only make laying plywood for floor leveling.

- Turned support as lathing. Of boards or veneer sheets cut separate support, the thickness of which will depend on the floor height differences. That will have as a single mesh, over which the plywood on the floor laying.

Each of these requires attention and patience during the preparatory activities, and during mounting of the material sheets. But in the end to get a really smooth surface, which can produce flooring flooring.

It is worth noting, that drilling should be carried out in two stages. To start making a hole for himself fasteners, and then - to the screw cap. Hat should ultimately completely drown in a sheet of plywood and have projections. To the nearest edge of the veneer is located must be located at a minimum distance 20 mm.

If the veneer sheet has a unilateral grinding, the unpolished side must stay upward, subsequent to planarization layer could have better adhesion. For a simple masking caps screws rotated upside polished side, which subsequently is sealed with sealant and painted.

alignment technology

Installing plywood on the subfloor includes three consecutive basic steps:

- specimen sheets.

- installation lag. This step can be omitted, if the process is to do without them.

- Fixing to the floor.

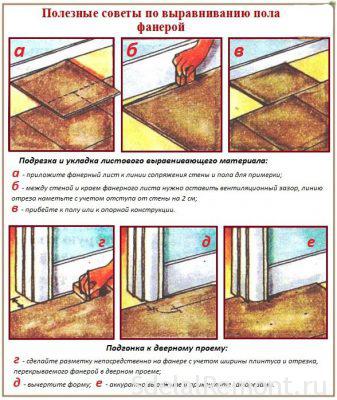

Plywood is cut-to-size rooms. This takes into account the seams of the walls in the room, as well as the distance between all the sheets from each other. Otherwise you are encountered with deformation of plywood after installation, which also contributes to changes in the level of humidity and temperature indicators. Even after cutting should be checked each item. If found to be defective in the form of bundles or cleavage, then it is better not to use the.

Further there is a sheet unfolding of the floor area and no harm will be number each of them in order, not to confuse. It is worth noting, that if there is a lag, all joints of plywood sheets should be placed in these areas.

As the lag can act as pieces of wood, plywood boards. The width is taken at least 30-40 mm. Fastening occurs to the base with screws or with an adhesive. special filler used to fill the space between joists. It is possible to further arrange a layer of thermal and sound insulation.

When all the above is satisfied, can Line floor plywood. For fixing sheets selected one of the schemes above. Do not be amiss to each element of plywood handle antiseptic. Fixing is usually done with the help of self-tapping screws with plastic plugs. It is in order, to a sheet of plywood does not crack, pre-drilling a hole occurs.

In some cases, a glue for plywood. The most important thing, that it is based on pine resin was. To tie the base sheet used dowel screws. The adhesive is applied not only on the basis of, but also on the inner side of the veneer. After laying on the surface of them immediately bolted screws. Once completed installation of all sheets in the floor area of the room, it is necessary to do the work with seams. They are treated filler, plaster or acrylic sealant. It will only seal at the top of the mounting strip.

polishing

On the surface of the plywood can be deburred and cuts. To get rid of them, produced grinding. The event also allows you to get rid of possible minor and invisible areas with elevation changes. For grinding is used not only sander, which can be rented, but also ordinary sandpaper.

As a result of this stage is the dust. It shall be resolved by the end of the grinding.

Checking the results

After completion of work, inspect the entire plane in the room. If the plywood sheets implemented qualitative alignment, then everything should look like this:

- There is no touch sheet walls in the room, and there is a gap left by the sheets.

- using the rule, defined horizontal. Checking is carried out in several locations throughout the area, constantly changing the direction of measurement. The slight deviation within 0.2 percent.

Using a wooden block, rattles surface. The resulting sound should be firm and the same on each of the sites. If you meet dull sound, it is likely that the plywood peeled off from the base. According to the building regulations, acceptable peeling veneer from the base on an area of less than 20% of the total leaf area. If this figure is greater, you will have to carry out the replacement of a new.