Often in multi-storey buildings to create a huge amount of noise from neighbors. This makes it difficult not only to fully sleep, and perform household chores. The optimal embodiment in this case will serve as a noise reduction apparatus. All the noise may take place not only between the walls, but also in the intermediate floors. This indicates, that particular attention is paid to the floor. Floor sound insulation in the apartment under the screed can be performed independently without extra effort.

options for noise insulation

To reduce noise in the apartment there are several options subfloor device. One simple can be called "soft floor". But he gets only by having a base, eg, wood floor. As materials usually act on the linoleum based felt, carpet, etc.. Among the disadvantages are the inability to mount in areas with higher humidity level.

Another option - use when laying laminate gasket, linoleum or hard, eg parquet. There must always be a sound-insulating substrate, capable of absorbing high levels of noise. Laying it does not take much time and is very easy. The most suitable material - polyethylene foam. Excellent fit and fibrous materials.

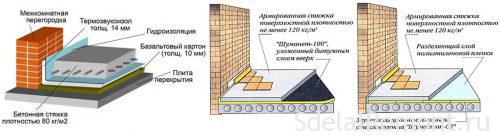

Impact noise can also be eliminated. This is usually arranged "floating" floors, with the main feature - no connection with any kind of floor covering. Consequently, the vibration of the sound does not get inside the apartment. In this way it is executed floor soundproofing in the apartment under the screed.

What work?

The paper can be used entirely different materials for sound absorption. This is due primarily to the use of different methods for soundproofing. The construction of the market represented a huge range, both domestic, and foreign production. It may be boards for sound insulation, mats on a basalt or glass, mineral wool and its varieties, bung, types of rubber, chipboard, slag with fine fraction, screenings of expanded clay, used to dry floor screed and many others.

LECA is most often the first device with soundproofing a tie on a wooden base. There is also a classification of materials as a function of the main components:

- mineral. They are based on using such components, as cement, mineral wool or expanded clay.

- plastic (polymer). Basically presented in liquid form, it can also be a foam or other reflective materials.

- silicate. The hottest - glass wool.

- Particleboard. plates, plywood sheets, as well as the usual chips.

Depending on, which has a material hardness, they are divided into:

- soft. Presented mineral wool, fiberglass.

- solid. May be mineral wool, but granulated.

- Semi-rigid. Wool has a honeycomb structure for use as a sound absorption element.

There is also a sound-reflecting materials, It is also actively used in the device in the flat floor screed. It is often hard materials in the form of plasterboard, brick and mortar, stone and other things. Some components can absorb a noise, but do not let it further. Thus the quality of materials have, have fibrous, cellular or granular component.

Each of these materials are poured in several layers, each of which is generally 40 mm. It is this "pie" will be enough, to fully comply with building regulations on the level of absorption of noise in the apartment.

modern materials

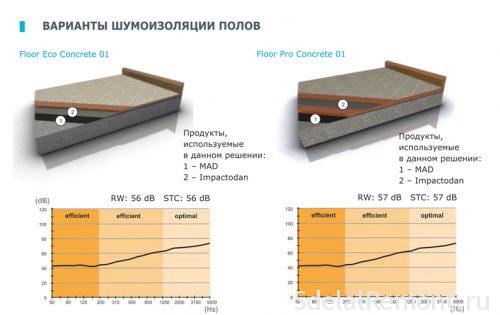

Technology does not stand still and is constantly offering the market multiple materials news, able to eliminate extraneous sounds indoors. Among them the popular "Shumanet", represented as a complex structure of elastic material. Most often it is implemented in rolls with a thickness 3 mm. It is able to protect from impact type noise. If you choose a tie in this case,, such a noise reduction is performed under the "floating" version. During the flooring to the subfloor must be held overlap, as well as to climb the wall to the desired level. The latter will depend on the filling level of the solution. All joints between the sheets themselves must be taped using construction adhesive tape.

Another option - Tescound. At its heart - the mineral aragonite. Despite the small thickness 2-3.7 mm, the effect of the use made known to maximum performance. subfloor construction with screed thus it remains virtually unchanged. In no way affects the height of the ceiling in the room to equip.  Thanks to the flexible membranes, installation process is straightforward and conducted as soon as possible. This material also has other positive attributes - the ability to withstand low temperatures, the appearance of mold and mildew during operation. Besides, further, any type can be laid floor covering. Sound insulation under screed get high quality apartment and meets the stated requirements.

Thanks to the flexible membranes, installation process is straightforward and conducted as soon as possible. This material also has other positive attributes - the ability to withstand low temperatures, the appearance of mold and mildew during operation. Besides, further, any type can be laid floor covering. Sound insulation under screed get high quality apartment and meets the stated requirements.

By "floating" screed can be used "Vibrostek-V300". In addition, it fits perfectly for finishing subfloor.  The thickness of the elastic rolls is usually 4 mm. They are quite laid back to back to each other, then lay on top special tape Vibrostek. Any difficulties during installation usually does not occur, if arranged floor screed with sound insulation. If floors are lags, then to create a protective layer against noise and sounds can be using such material, like Isover. They are distinguished by ease of construction.

The thickness of the elastic rolls is usually 4 mm. They are quite laid back to back to each other, then lay on top special tape Vibrostek. Any difficulties during installation usually does not occur, if arranged floor screed with sound insulation. If floors are lags, then to create a protective layer against noise and sounds can be using such material, like Isover. They are distinguished by ease of construction.

When insulation is needed in the apartment floor under the screed materials can be very different. Everything will depend on the specific conditions of work, as well as the option selected floor screed pouring.

Creating a floating floor

some think, what strainer soundproofed floor apartment requires special knowledge and waste time, forces to carry out installation. But to study in detail the technology, to perform on their own the entire scope of work.

To begin to prepare the basis for a floating floor, meet the following requirements, the purity, dryness and evenness.  From the quality will depend on the final result and the life of the resulting construct, protects from increased noise level. We should make every effort and do not rush.

From the quality will depend on the final result and the life of the resulting construct, protects from increased noise level. We should make every effort and do not rush.

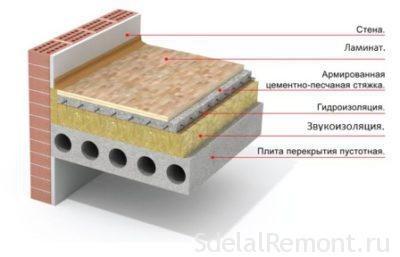

Any flooring, that was previously, must be removed. Then established the existence of height differences, which should be brought to the horizontal plane. projections astray, and potholes are sealed. As a material for generally used screed of sand and cement or self-leveling mix.

The next stage - the formwork device. After completion of the work should not form the so-called acoustic bridges. With this help cope insulating sheathing from all existing partitions and walls. For this purpose, a temporary formwork made of plywood, plasterboard or thin boards. It is mounted on the perimeter of the room, which hosts works. As soon as the screed will be frozen, formwork is removed, and all the space is filled with foam or the available balance of the material for soundproofing.

Once the base is ready to work, it was disintegrating soundproofing material. It is worth paying attention to, that there are no gaps between the elements, and slots. All this can lead to the leak sound. Consequently, all work will be reduced to zero utility. To waste at stacking was the minimum number, the beginning of work carried out by the selected angle in the room. If necessary, the joints of the sheets or plates are glued additionally.

At this all work completed, and can start casting solution prepared using. Further arranged reinforcing layer. Due to this, the screed thickness is obtained at least 50 mm. If we make a thinner layer, it is unlikely to succeed to hide the reinforcement elements.

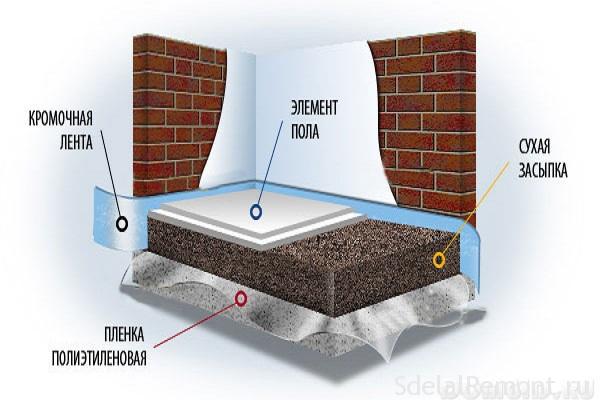

Floating dry screed

Singled out dry floating floors. Originally the selected quality material for noise absorption. The most effective of them will be a mineral wool, having a high index of noise reduction. When the thickness of the plate in 2 cm, it is able to extinguish 46.5 dB noise.

Special nuances there is no. The case concerns only the filling floor screed, which is carried out after laying the material minarelovatnogo. After careful tamping backfill, she leveled on beacons exposed. We must not forget about this when the edge band, which is fixed around the perimeter of the room. It is also attached along the existing decorative elements, posts, columns and other. The tape runs as a material for soundproofing screeds in apartment. Typically, the thickness is taken in 20 mm. If there are excess and protruding elements, they can be easily cut with a sharp knife. But to do this it is recommended after, all kinds of work to be completed.

After that, formed as a filling, stacked on top of the plate in two layers gipsovolokna. Connecting joints in this case should not coincide with each other. Between the sheets are glued with glue PVA, then further fastened with screws.

The popularity of this phase noise insulation under dry screed is the absence of "wet" steps. Each element of the resulting "cake" ties exhibit sound insulation quality. After that, both sheets stacked gipsovolokonnyh, you can begin to work on the flooring floor covering. Total thickness of the entire structure is 30-40 mm.

Sound insulation under laminate

When carried out under the floor insulation laminate, you should think about choosing a high-quality material to work. From him, and will depend on the absorption of sound (cork, of polymer film). He, in turn, will be the substrate.

If the tube is chosen as a main component, you can be sure, it's really a natural material. It is much more effective than struggling with soundproof floor apartment under the laminate. Some misses cork because of the high cost of. But as there is not worth saving, since the structure is able to serve for a long period.  Installation of the plug takes a minimum of time and involves stacking bales on a base close to each other, then all joints are held together by duct tape. This indicates, that the sound insulation floor in an apartment without a tie has enough advantages, especially for novice builders and repairers.

Installation of the plug takes a minimum of time and involves stacking bales on a base close to each other, then all joints are held together by duct tape. This indicates, that the sound insulation floor in an apartment without a tie has enough advantages, especially for novice builders and repairers.

There are ample and modern materials for sound insulation under the laminate, including rezinoprobka, substrate Teksaund. This method is suitable for the chosen floor covering for the reason, that create a flat surface of the rough concrete screed is practically impossible. That's what runs the floor insulation in the apartment without ties.

Alternative material - an elastic foam, having a closed cell system. The same applies to cellulosic sheet materials or foam polystyrene. They also act as a substrate, but, in turn, have a much lower level of sound absorption, than cork material.

Regardless of, exactly what material is used as sound insulation subfloor, further fastening moldings should be administered to only one surface. This may be a wall or a floor. When additionally must be applied between the wall of the gasket or rubber stoppers. Nails should be removed, as they may be to perform the conductors of sound into the room.

rules laying

Noise insulation under the floor screed must be performed in strict accordance with the requirements of. There are certain subtleties, to which you should pay attention when installing. This is primarily As for the noise insulation material. Too soft it is not worth taking, because it can prosest to tie itself over time. For premises optimal rate - 5 mm. To do this on the packaging there is an abbreviation from "CP5" figure.

If the design will have several layers, the first should be placed soft mats, and on top of them - more durable compression material for insulation. Thus it is necessary to pay attention to the seams of each layer, as they do not coincide with each other.