The floors in any structure can be attributed to the number of seats a large heat loss. This applies especially to the concrete floor, since the surface itself without sufficient insulation has low temperature. High-quality insulation in multiple layers will get rid of the problems. All types of work are not of particular difficulty, but will vary depending on the material used in. It is only necessary to strictly follow technology, to get warm concrete floor.

Features warming

Before you begin warming the concrete floor, should dwell on the specifics of the technology, and selecting a particular material for mounting. The work included some very important step, which must be performed in succession.

- The first step is carried out prior to pouring the concrete floor solution.

- In the process of creating a concrete floor.

- When the stack of any type of floor covering.

To start work on creating a warm concrete floor from the outset. Only then you can get a really high quality results. insulation level will be at an altitude of.

There are quite a number of methods for insulating concrete floor. Each of them can be made at a certain stage of the floor installation. They can be used in combination with each other, as well as individually. Everything will depend on the specific situation. If you can not make laying insulation under screed, it should stay on the use of the expanded clay, and later - the final coating in multiple layers. But when we are talking about warm floor, the warm coating on the finish can not do.

Material requirements

The insulation material has the features. But at the same time to it must meet certain requirements. Its quality will depend on the period of operation, as well as all possible characteristics, properties. The following basic points, that should be inherent to that used in the insulation for concrete floor:

- Compressive strength.

In operation, external pressure is exerted on the floor. Consequently, insulation itself must remain intact even under pressure, any load.

In operation, external pressure is exerted on the floor. Consequently, insulation itself must remain intact even under pressure, any load. - moisture permeability. The material must be able to pass through a certain amount of moisture. Any savings it should not be, or this item is reduced to the minimum figure. Otherwise, all the properties of the insulation will be lost at all.

- Density. Strength is higher, if the above is this characteristic. But immediately begin to suffer material porosity, resulting in an increased degree of heat conductivity. To happen at the proper level insulation of concrete floor in a private house, should choose insulation with a density of 50 kg per square meter.

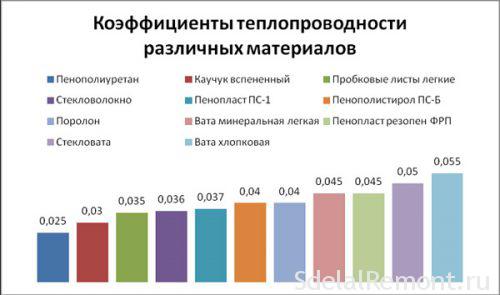

- Thermal conductivity. Quality material would be the case, when the coefficient of heat passage below. There is a minimum level limits - 0.110 W /(m * K).

- water vapor permeability. A higher rate indicates a better quality of the material. When skipping the pair regulated air exchange between the environment and the building itself. Consequently, for the people inside the room are optimal conditions for living.

Scheme insulating floors

DSP

Many think that, how to insulate concrete floor in a private house. Where you can pick up a lot of material to work. Among them, the particle board released. It is perfect for the concrete base. Located in a part of the insulation to the concrete floor shavings able to minimize noise. But this in itself it holds the required level of heat.

On the final quality is influenced by the layer thickness from the chip. Minimum rate - 22 mm. If the layer is less than, the result will be null and void.

installation process is very simple and does not take much time. To start plank waterproofing layer, which may be a conventional plastic film, and thereafter tightly fit to each other chipboard sheets. Next will only implement the selected option deck flooring.

Raised floor and plywood

Another option for insulation concrete floor - creation of the false floor boards or veneers.  Sex becomes noticeably warmer, but becomes one major drawback - the room is reduced in height by about 20-25 cm. If the room is already low ceilings, then this option is best put aside and consider other available.

Sex becomes noticeably warmer, but becomes one major drawback - the room is reduced in height by about 20-25 cm. If the room is already low ceilings, then this option is best put aside and consider other available.

Created by wood joists, which are subsequently stacked plywood. The resulting space below the plywood can be completely filled with any material for insulation. This option of creating a warm base facilitates the application of any further coating on the floor. Limitation does not appear.

Izolon

Not so long ago there was such a material for insulation concrete floor, how izolon. It can be called the new technology, presented in the form of foam bases.  Izolon perfectly suited as a substrate for such floor coverings, as laminate or parquet.

Izolon perfectly suited as a substrate for such floor coverings, as laminate or parquet.

Laying process does not take a lot of time and requires a minimum of knowledge in the construction industry. It is spread onto a concrete floor from a roll of material. It only remains to stick it on the basis of using the adhesive tape foil. It is in this manner and it occurs on the surface of fixation.

Styrofoam

Enormous popularity of the insulation to concrete floor. In addition to the foam has an absorption properties of sound. It's very easy and convenient to stack, processed and cut into the required size. The density of this material is to say about the compressive strength. This should be maintained all the other useful properties. When installing the foam should comply with certain conditions:

- Careful preparation of the base. Is cleansed of debris and dirt, then arranged waterproofing layer of polyethylene film. The film should have an appropriate thickness and each subsequent sheet is laid overlapping the previous approximately 100 mm. For fixing the films used scotch.

- After that, close to each other, as well as to the walls and other structures stacked sheets of foam. To subsequently during the operation at the base of the floor did not get wet, after the foam layer is laid another layer of the film for waterproofing.

- Creating a reinforcing layer and filling floor screed, wherein the thickness is generally at least 50 mm.

Scheme foam insulation

Maximum efficiency material inherent concrete floors, are arranged directly on the ground. Wherein each insulation sheet thickness must be at least 100 mm. Only in this case the result is the best and there is no further question arises, how to insulate the concrete floor.

The foam can be used on ground. For this purpose, initially the base is filled with gravel layer in the 40 cm. "Cushion" should be carefully tamped. Next poured 100 mm layer of sand. It has to be pressing of the "pie".

When all of these activities are completed, arranged rough base of reinforced concrete. Once the solution has dried, of polyethylene film is laid and foam insulated all.

Quality is immediately noticeable: heat will leave less, increase the level of sound insulation, live and be in the room to be comfortable.

cork

Environmentally friendly insulation of concrete floor stands cork. Besides, it possesses such qualities, how practical, ease, the high degree of heat retention and moisture repulsion.  Stacking of cork material may be performed directly on a concrete base, without additional layers of waterproofing.

Stacking of cork material may be performed directly on a concrete base, without additional layers of waterproofing.

After installation of the plug perfectly decorated. The material can be processed, varnish, paint. The thickness of the cork plate will depend on the requirements of, which are shown by the level of thermal insulation. That will have a warm floor in the concrete slab.

Insulating paint

When I arranged a concrete floor, it can be easy to insulate, using a heater to a concrete floor, as an insulating paint. Many will wonder once, how to insulate a concrete floor in the building in such a way. The prepared surface of the base (stain removal, mud, dust) It leveled with cement mortar. To fill cracks, voids and crevices uses liquid Penoizol, which is incorporated into the building by means of a syringe.

As soon as the screed after pouring grab and completely dry, can be painted. Usually the coating is at least 2-3 layer. Everything will depend on the requirements and the need for insulation. But there is very important condition - a coat of paint to the next application should dry for at least days. Only in this case will turn out good thermal insulation. So what you should know about, how to insulate the concrete floor.

"Warm floor" system

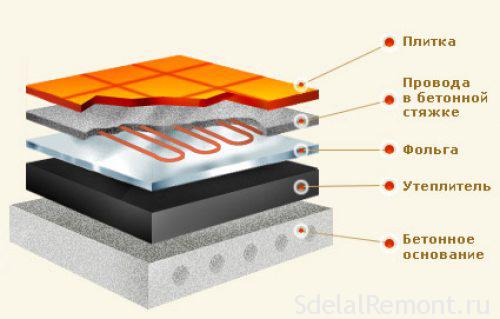

Another very popular option to make insulation in the concrete floor house - creation of a "warm floor" system. According to this base can move around comfortably even barefoot. There are two versions of the device - a water and electric warm floor. Each of them has its own characteristics and nuances. It is considered more difficult concrete water floor. There is further carried out the installation of equipment for heating, and forced circulation. This is reflected in the labor costs and the amount of work done.

The entire system can be placed on the layer of insulation. At the same time we must not forget about the important feature, how to arrange warm concrete floor - the material must be coated with a foil, to be able to reflect the heat coming into the room. No heat should not occur. If the use of any other material, the further barrier foil is laid on top of.

Once the system is arranged and stacked on the base, launched and tested, possible to arrange the reinforcing layer and the fill solution for floor screed. It is worth noting, Concrete solution that can do without adding expanded clay or gravel.