Self-leveling floor got its name due to the fact, that are able to independently distributed over the surface, effortless. Also used herein Self Leveling mixture. In spite of all this large area of the room, as well as a sufficient layer 10-15 mm requires attention and control on the part of the Executive. For this reason, when installing self-leveling floor is used for various kinds of beacons, allow to obtain a perfectly flat surface.

notion

When used for lighthouses self-leveling floor, it not only simplifies the operation process, but also helps to reduce labor during installation. With their help, the floor is determined by the thickness of the future and is set its height.

But there is one feature - the need to have some knowledge on beacons, the rules of their billing and type of construction, depending on the situation. In addition to the factory equipment, they can be performed independently. On hand only should be the appropriate materials and tools. Consider the basic details 8 ways lighthouses installation under screed.

types of lighthouses

There are two types of lighthouses, used for mounting self-leveling floor:

- rack accessories. They will be useful not only for the "wet" ties, but also "dry". In the second case, it is about to fall asleep quartz sand.

- Professional benchmarks.

It is worth noting, they can be made of various materials. All will depend on the version of the device self-leveling floor, installation process and requirements.

rack design

It is very difficult to make installation of self-leveling floor and it does not use beacons. They should be prepared to start work, so that in the future no difficulties and distractions. The following types of rack designs:

- of solutions. Are used for the thin layer of self-leveling floor. The screws are screwed into the floor at a certain level, to the upper part of which is attached cord. Produced under this cord laying solution thus, that he formed after drying guide. It will contribute to the quality management thickness.

- wooden. The oldest method of performing a beacon of bars, section about 2.5 cm. To adjust the height, enough bars wedges under a certain size. When they increased humidity change their dimensions and parameters, that referred to the serious shortcomings.

- Of the steel pipes. Used indoors, having sufficient area. In addition, there is provided and sufficient the inlet floor thickness - least 4-5 cm. The cross section tubes may be different, not only round, but square. Even under pressure, they are able to retain its original appearance.

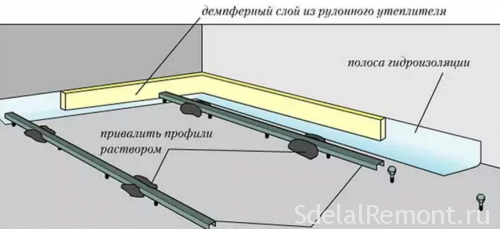

- metal. This standard metal profiles. Scope - compact room. The screws are screwed into the profile DATA, used as height adjustment and thickness of the tie layer, that does not exceed 2.5-3 cm. at higher load profile, structure can deform. The result will not really nice.

- mortar slide. The amount will depend on the circumstances and requirements. Most suitable as a guide for dry packing. The solution is distributed over the surface of slides to a level using rules.

Installation diagram slatted beacons

Shtыrevыe beacons

If the specialist has sufficient experience in Self-leveling floors indoor, they can be used in pin landmarks. They are used in casting due to the properties of the final solution, capable of self spread over the surface and at the same time have a sufficient power level dry surface.

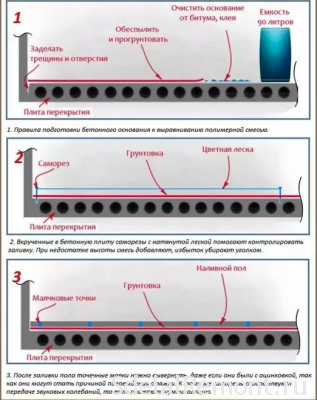

Pin beacons - conventional screws with hex cap, intended for screwing the respective screw driver. Screws are screwed into the base, and it comes pouring solution for the self-leveling floor. more precisely, It happens pulling the fishing line, which is used as a reference.

Such a method can only be used on a concrete base. Otherwise waterproofing layer is broken, tightness. And it is necessary for the base of the timber. In the latter case the screws simply are not allowed.

Selection of screws length will depend on the power of the floor. There is also a kind of sequence of actions when using pin lighthouses:

- Near the wall, opposite the entrance hole is made at a distance 30 mm. They inserted the plug of polymer material. Alternative to it - a piece of wood of the appropriate size.

- Screwing the screws to a certain extent by landmarks, established by means of a laser leveling.

Rules setting pin lighthouses - Between the screws tightened fishing line or other sturdy and reliable lace, parallel to the floor of the future.

- As noted above line fishing line screws screwed similarly to step 50-60 cm. More experienced it will be sufficient to apply the step 100-140 cm. the main thing, to the appropriate length was typically. It should fall on the available support.

- Further, the fixing of beacons across the floor space, where the wire mounting self-leveling floor.

Pouring on the floor pin beacons

To sound insulation level was not reduced, after work screws are turned out, and the available slots are sealed ready solution.

Use rapper

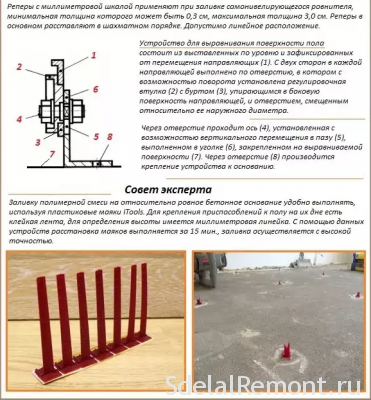

No master will not rely on all the qualities of a polymer rovnitelya in terms of a good yield and ability to independently distributed evenly over the entire surface. In this case, the reference points for self-leveling floor. With their help, kept horizontal with a precision to fractions of millimeters.

Fine frame determines the level of the inlet for pouring the floor and is a structure in the form of three legs. In its central part there is a rod made of metal. This pin and help to establish the height of the next floor in the whole house. In their upper part in the future, you can set the level of hydraulic, from which will be determined by the zero point.

An alternative reference points are the beacons for pouring plastic floor, also having a scale division in millimeters. They can be attached to the base using adhesive tape on the bottom or screws. The truth in the latter case will be somewhat difficult to remove the device after the casting. Alignment of lighthouses plastic is very fast - within 15-20 minutes. The most important thing, with the result that the maximum smooth surface is obtained because of the high accuracy of elements, as plastic beacons for pouring the floor.

Step data setting beacons of one meter. But an inexperienced worker can hardly qualitatively put them into practice. This requires a certain skill and careful preparation. The frames are removed immediately after, as will razravnen solution across the floor space.

installation rules

Mounting beacons on the floor surface must be performed carefully. Otherwise, the problem will get even surface. To start determines the zero point, which is considered ideal for all other beacons installed. Between them should exhibit the same distance over the entire area.

Installation of lighthouses is best done with a laser level. With the help of notes on the wall level curve by control points, interconnected.

In every corner of the room it is necessary to determine the distance from the floor to the control point. Not rare, where the highest point is located roughly in the middle of the wall.  Because of this cable should be carried out at a metered point to the opposite wall on the control points level. When it will not cling to the process of transition, then you can begin to fill self-leveling floor a beacon. Otherwise, you will bring down the protruding elements using chisels or put new zero (if the hill can not be eliminated).

Because of this cable should be carried out at a metered point to the opposite wall on the control points level. When it will not cling to the process of transition, then you can begin to fill self-leveling floor a beacon. Otherwise, you will bring down the protruding elements using chisels or put new zero (if the hill can not be eliminated).

mount technology

When the set point beacons to fill the floor, should follow a specific sequence of actions:

- Minimum height screwed screws must not be less than the thickness of the solution. However, their average spacing should be 50 cm.

- Distance from the nearest beacon to the wall - 30 mm.

- One lighthouse (reference point) the second from the top level is set, on which it is set the required height. Similarly, the fixation of all other elements in the room.

- Step screws can be increased, if you use the two-meter level. Truth and experience in casting self-leveling floor on beacons with distance should be.

- The height of the screws between the end elements adapted to eye, to the level of line or cord spanned.

Beacon for floors should not remain in solution after solidification. This applies to the cases and their location points on the upper level of the solution. subsequently,, if necessary, grinding, they will create a lot of problems.

After reviewing all the recommendations, everyone will know that, how to use beacons at floor filling. They will provide quality performance as a result of a perfectly flat surface over the entire area in the room. The use of beacons to self-leveling floor It is not a prerequisite for the holding assembly. But in the end they contribute to getting fitted at the base of all the parameters. Their cost minor, and the result justifies the spent force. The main thing - the right to determine the zero level in the room and from the start installing beacons.

If there is no confidence, that such work must be entrusted to specialists. Payments will be nicer, than the subsequent dismantling of the entire construction self-leveling floor.